Kettle type reboiler design pdf

Kettle Reboiler design, This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers. The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial

4 Column-Base and Reboiler Arrangements 4.1 INTRODUCTION t he design of a column base with its associated reboiler can be a comdex ~ â matter. It requires simultaneous consideration…

PDF There are several design criteria concerning the dimensions of the vapor space in kettle reboilers. These criteria are listed and commented in this article. An numeric example illustrates

Kettle reboilers are the easiest type of reboiler design you could use for your distillation process. A kettle reboiler is designed to allow a heating fluid to pass through tubes that are covered in the liquid you want to be distilled.

The TEMA K shell, also termed a “Kettle Reboiler” is specified when the shell side stream will undergo vaporization. The liquid level of a K shell design should just cover the tube bundle,

There are generally Two type of reboiler used in industrial distillation column. Kettle type reboiler:- For the following condition we can use kettle type reboiler: Pressure drop in kettel type reboiler is lower so it is suitable for the Vacuum services. In kettle type reboiler liquid totally

Reboilers provide vapor for a distillation tower. The most common type of reboiler is some variant of a shell-and-tube (S&T) exchanger — because such exchangers can satisfy a wide range of process and mechanical requirements at reasonable costs.

Sat, 08 Dec 2018 11:34:00 GMT reboiler kettle design pdf – Types of reboilers. The most critical element of reboiler design is the selection of the proper type

mixture of liquid components into two products using the heat provided by a kettle-type reboiler. Types of reboilers The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such reboilers. However, other heat transfer fluids

Kettle Reboiler Design (KRD) v.1.0 This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the

8/12/2018 · A kettle reboiler is a heat exchanger used in a chemical distillation process. This shell-type exchanger has a large open boiling surface much like a kettle on a kitchen stove.

GENERAL DESCRIPTION A highly-detailed scale model of a kettle-type reboiler, supporting training in the operation and maintenance of industrial heat exchangers. This model reflects design standards established by the Tubular Exchanger Manufacturers Association (TEMA) and the ASME.

Calculations msubbu.in

Free Kettle Reboiler Downloads

Kettle Reboiler 40 Thermosiphon Reboiler 47 . KLM Technology Group Practical Engineering Guidelines for Processing Plant the shell, depending on the type of reboiler The following design guidelines should be considered when the selection of a reboiler type is made. 1. Fouling -Tube-side is easier to clean than shell-side. 2. Corrosion – corrosion or process cleanliness may dictate the use

There are several different forms of reboiler which may be used with a distillation column, each of which has both merits and drawbacks. Guidance is required in selecting the most appropriate form for a …

tough kettle design (inspite of what others may say or write). This is true not only of the reboiler application but also This is true not only of the reboiler application but …

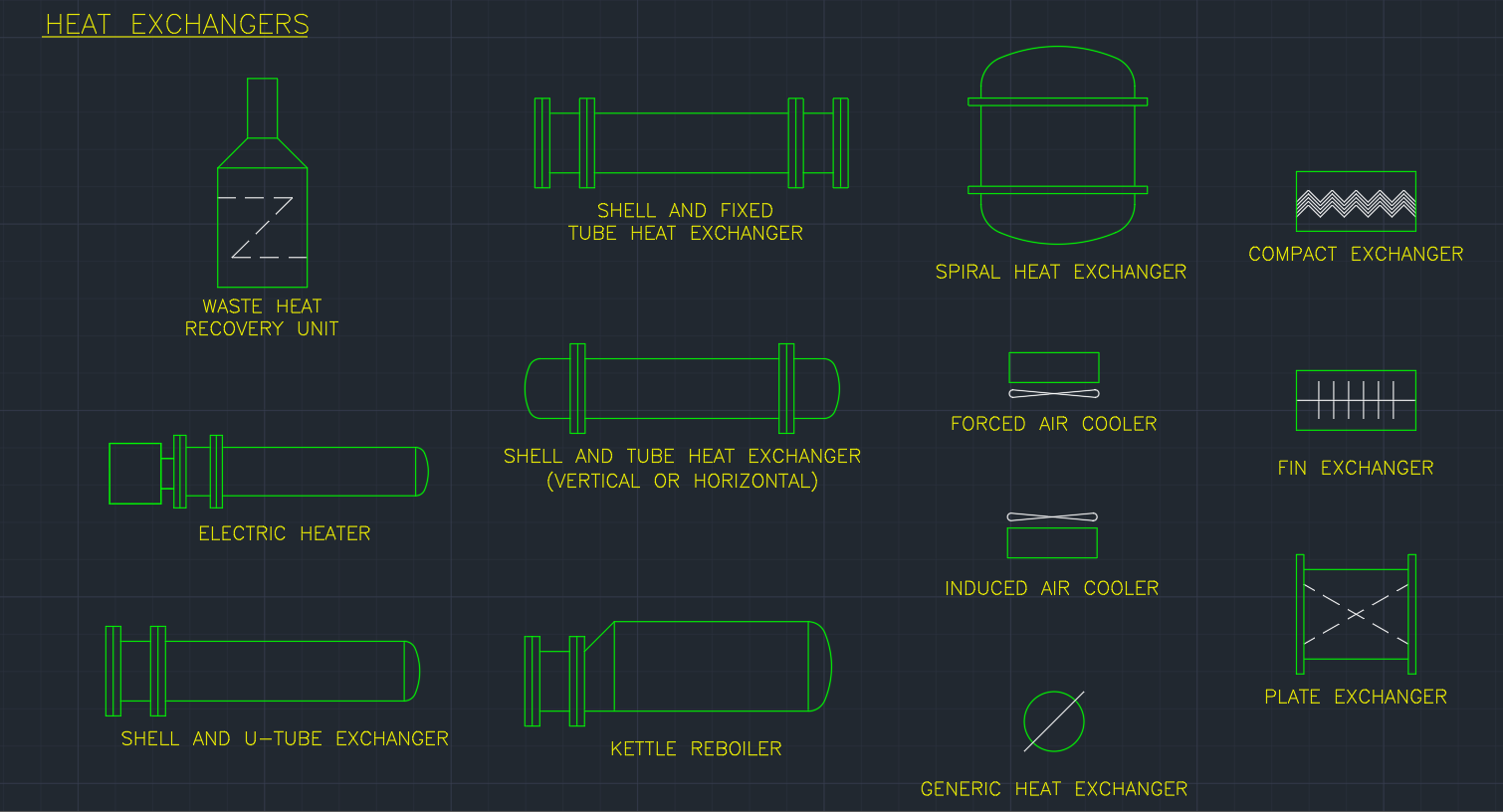

Design of Kettle reboiler . NPTEL – Chemical Engineering – Chemical Engineering Design – II Joint initiative of IITs and IISc – Funded by MHRD Page 2 of 41 Lecture 1: Heat Exchangers Classifications 1. PROCESS DESIGN OF SHELL AND TUBE EXCHANGER FOR SINGLE PHASE HEAT TRANSFER 1.1. Classification of heat exchangers Transfer of heat from one fluid to another is an important …

maintenance design for distillation tower reboiler system. The thermosyphon reboiler contains the two The thermosyphon reboiler contains the two endearing qualities of the evaporator, namely mechanical simplicity and operation in the nucleate

It has a reboiler section with a subsection for kettle reboilers. There is an example for calculating the shell diameter and an example for designing the complete reboiler. There is an example for calculating the shell diameter and an example for designing the complete reboiler.

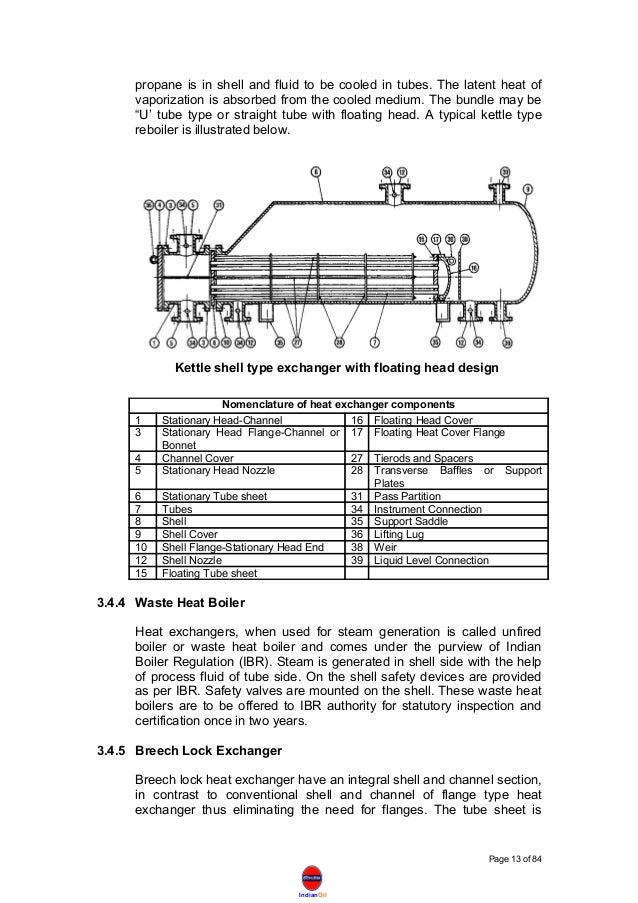

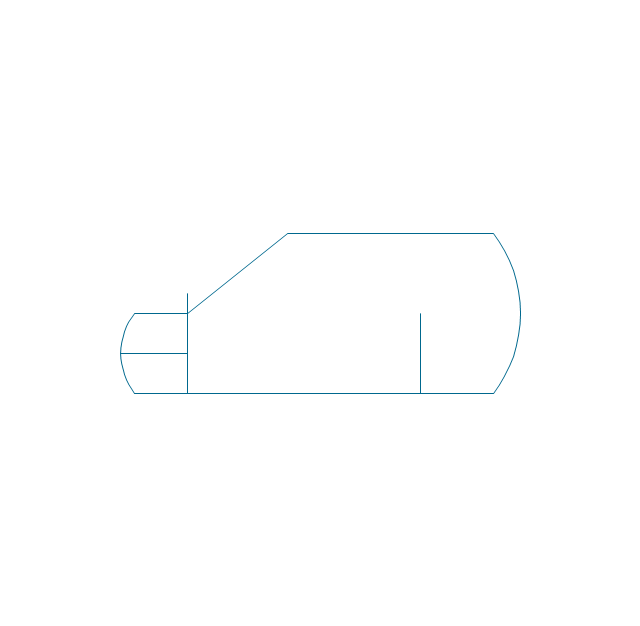

English: Cross-sectional diagram of an operating Kettle-type Reboiler used for industrial distillation towers. H Padleckas modified an image on November 4, 2006 originally created by User:mbeychok called “Kettle Reboiler.PNG” and uploaded to the English Wikipedia on November 2, 2006.

The design provides the flexibility of a U-tube design with an extended shell length that improves the exchanger’s ability to achieve close temperature approaches. Advantages

After describing the various types of evaporation “pool boiling, flow boiling, flash evaporation,” the different types of reboilers are introduced: vertical and horizontal thermosiphon reboiler, forced circulation reboiler, flash evaporation, kettle reboiler, internal evaporator, falling film evaporator. The design procedure for kettle-type reboiler and falling film evaporator is shown.

Fig. 52.5 TEMA X-type shell. K-Type This type is used exclusively for kettle reboilers and vaporizers, and is characterized by the oversized shell intended to separate vapor and liquid phases, Fig. 52.8.

Kettle Reboiler Type Heat Exchanger Manufacturer INDIA. Kettle reboilers are very simple and reliable. They may require pumping of the column bottoms liquid into the kettle, or there may be sufficient liquid head to deliver the liquid into the reboiler.

The TEMA K shell, also termed a “Kettle Reboiler” is specified when the shell side stream will undergo vaporization. The liquid level of a K shell design should just cover the tube bundle, which fills the smaller diameter end of the shell.

feeding the kettle reboiler. The kettle uses main column LCO pumparound heat between 450°F and 465°F, with the outlet temperature varying from 240–260°F. Throughout startup, there is little heat available from either debutanised gasoline or LCO pumparound due to low stream temperatures. As a result, the supplemental steam reboiler was added. While this is increasingly common, adding a

Kettle Reboiler Design (KRD) v.1.0 Advertisement This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

Kettle Reboiler Design 2.0.0 Date: February 13, 2014 This user friendly software is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

20/04/2018 · This is version 3.0 demonstration of Kettle Reboiler Design Software. This product allows you to do thermal analysis calculations for Kettle type reboilers. The software is …

The most critical element of reboiler design is the selection of the proper type of reboiler for a service. Most reboilers are shell-and-tube exchangers. Specific services may use other specialized designs including stab-ins, plate-fins, spiral-plate and others. The purpose here is not to go into design details of each specific type but rather to examine the selection criteria that favor one

accommodate the reboiler. This may cause a mechanical design problem with the column. Stability of the column may become an issue. 2 Horizontal Thermosyphon Reboiler This is perhaps the most common type of reboiler. A horizontal thermosyphon reboiler consists of a horizontal shell and tube exchanger with a single horizontal baffle. The process fluid flows along the shell-side along the length

reboiler design and operation to ensure proper venting, correct arrangement of steam traps on reboiler supply lines, compatibility of materials of construction, and impact of current system operation (i.e. dry, partially or totally flooded on the steam side).

www.msubbu.in Ex-2 Kettle Type Reboiler It is required to design a kettle-type reboiler to vaporize 5000 kg/h of n-butane at 5.84 bar. The minimum temperature of feed will be 0 …

Heat Exchanger Type 8 (A) Shell & Tube Exchanger 8 (B) Plate Heat Exchangers 14 Figure 17: Kettle Reboiler 64 Figure 18: Recirculating Thermosyphon Reboiler on Column Bottoms 65 Figure 19: Once-Through Reboiler With Bottoms Tray Feed 65 Figure 20 : Pump Around Reboiler on Column Bottoms 66 Figure 21: Normal Crossflow Fraction 73 Figure 22 : Baffle Spacing Correction 74 Figure …

Types of reboilers. The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such reboilers.

chemE610, Kettle type reboiler is a type of shell and tube heat exchanger with differences in design basis some of which are as follows: 1) As a submerged bundle equipment, it’s a pool boiling device which has to be designed based on the data for nuclear boiling.

Kettle Reboiler Heat Exchanger This software can make

Decide type of exchanger i.e. fixed tube sheet or U- shell (use U-tube reboiler for large temperature difference), tube size (diameter, length, tube pitch), layout, effective tube length.

Kettle reboilers are widely used in the petroleum and chemical industries; their main problems are that of ensuring proper disentrainment of liquid from the outgoing vapor and the problem of the collection of scale and other solid materials in the tube bundle region over long periods of operation.

Kettle Type Reboilers • Kettle reboilers, and other submerged bundle equipment, are essentially pool boiling devices, and their design is based on data for nucleate boiling.

1 SCOPE This Process Engineering Guide is designed as an aid to the selection of reboilers for distillation columns. It describes the various options and details their merits and drawbacks. 2 FIELD OF APPLICATION This Guide is intended for process engineers and plant operating personnel in GBH Enterprises worldwide, who may be involved in the specification or design of reboilers. 3 …

288 Kettle-Type Reboiler, Heat Exchanger Model Product Dimensions (L x W x H) 27in. x 10in. x 15in. (700 x 250 x 375 mm) 10lbs. (6kg) Shipping Dimensions

The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such reboilers.

9/10/2010 · YouTube Premium Loading… Get YouTube without the ads. Working… No thanks 3 months free. Find out why Close. KETTLE TYPE REBOILER HEAT EXCHANGER HW-ARTS. Loading… Unsubscribe from HW-ARTS? – central boiler 6048 owners manual PDF For economical separation of ethanol from water, selection of reboiler is main criteria. Selection of reboiler depends on space utilization factor, steam requirement and service life.

Thermosyphon reboiler dapat disusun secara horisontal ataupun vertikal, ini tergantung dari design prosesnya atau ketersediaan lahan. Reboiler type inipun …

when a vertical-thermosyphon, forced-circulation, or kettle-type reboiler is used: l. Spacing between the vapor-return nozzle and the lowest tray should be large enough to minimize entrainment of liquid drops in the rising vapor. This is typically one vapor nozzle diameter and normally will be specified by the column designer. 2. The maximum liquid level should not be too close to the vapor

Fractionation Research, Inc. RESEARCH – KEY TO BETTER DESIGN Hydraulics of Kettle-Reboiler Circuit on Distillation Columns Ton yy, , Cai, Mike Resetarits, and Ahmad Shariat

Kettle Reboiler Design calculations – Download Notice. Using Kettle Reboiler Design Free Download crack, warez, password, serial numbers, torrent, keygen, registration codes, key generators is illegal and your business could subject you to lawsuits and leave your operating systems without patches.

Kettle Reboiler Type Heat Exchanger . Kettle Reboiler Type Heat Exchanger is a retaining wall or overflow weir separating the tube bundle from the reboiler section where the residual reboiled liquid called the bottoms product, Kettle Reboiler Type Heat Exchanger bundle is kept covered with liquid.Kettle reboilers are reliable in that they can

The domed top section of the reboiler separates the vapor and the liquid.LECTURE EIGHT 054410 PLANT DESIGN Kettle Reboiler In this type of thermosyphon reboiler circuit: Liquid flows from the column sump to the bottom of the kettle’s shell. The vapor flows back into the tower via the riser.

Kettle Reboiler Heat Exchanger type exchangers are essentially a pool boiling devices. Their designed is based on data for nucleate boiling. In the tube bundle the vapor rises from the lower rows of the tube passes over the upper rows.

This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

Lewin Reboiler Circuit Design How reboilers work The driving force to promote flow through this reboiler is the density difference between the fluid in the reboiler feed line and the froth-filled reboiler return line. For the example on the right: ∆P = (20 ft ) ( 0.

Publisher Description. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

Reboilers. UnitOperationsI ReboilerReboilerarrangements arrangements Forced-circulation Natural-circulation Once-through Recirculation. UnitOperationsI Forcedcirculationreboilers Predictablerecirculationrate High velocities Low percentagevaporisedper circulation Suitablefor: Viscousfluids Heavilyfoulingfluids Pumpingcosts Smallinstallations High pressuredrops(low …

(PDF) Internal reboiler in distillation column ResearchGate

Engineers may design flat bundles in kettle reboilers by removing tuberows from round bundles to create a larger disengagement space. This webinar discusses application of the kettle reboiler circulation boiling model to flat bundles.

Kettle Reboiler Design. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers. The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

No hassle reboiler selection Reboiler selection guide eliminates the guesswork in choosing between a standard kettle type exchanger or a thermosyphon exchanger for reboiler applications D. L. Love, The Pro-Quip Corp, Tulsa, Okla. housing a reboiler design depends on several fac- tors: 1. Flow pattern of the feed and the percent vapor of the feed, 2. Viscosity of the feed and 3. Liq- uid level

these are enhanced kettle type reboilers and condensers using propane refrigerant in the pre-cooling system to cool down both the feed gas as well as the mixed refrigerant from the

is very high, this type of reboiler should be preferred [3]. The special design for the bottom of the column in figure 1(C)ensures a fixed liquid level feed to the reboiler

Kettle Reboiler Design standaloneinstaller.com

Lecture 6 Condenser and Reboiler Design

Select the Right Reboiler Chemical Processing

“Managing Reboiler Steam-side Operation

Kettle Reboiler Design 1.0 Free download

Reboiler Selection Article CHEE10010 Chemical

https://en.wikipedia.org/wiki/Reboiler

ENHANCED TUBES FOR THE PROCESS INDUSTRY Thermal

baxi duo tec combi boiler manual – Distillation Ch4 Reboiler [PDF Document]

Selection of Reboilers for Distillation Columns SlideShare

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

REBOILERS Thermopedia

engineer thinks naturally in terms of the A sketches and

Kettle Reboiler Type Heat Exchanger Heat Exchanger

4 Column-Base and Reboiler Arrangements

Publisher Description. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

PDF There are several design criteria concerning the dimensions of the vapor space in kettle reboilers. These criteria are listed and commented in this article. An numeric example illustrates

Kettle reboilers are the easiest type of reboiler design you could use for your distillation process. A kettle reboiler is designed to allow a heating fluid to pass through tubes that are covered in the liquid you want to be distilled.

Kettle Reboiler Design. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers. The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

The most critical element of reboiler design is the selection of the proper type of reboiler for a service. Most reboilers are shell-and-tube exchangers. Specific services may use other specialized designs including stab-ins, plate-fins, spiral-plate and others. The purpose here is not to go into design details of each specific type but rather to examine the selection criteria that favor one

is very high, this type of reboiler should be preferred [3]. The special design for the bottom of the column in figure 1(C)ensures a fixed liquid level feed to the reboiler

Decide type of exchanger i.e. fixed tube sheet or U- shell (use U-tube reboiler for large temperature difference), tube size (diameter, length, tube pitch), layout, effective tube length.

Kettle Reboiler 40 Thermosiphon Reboiler 47 . KLM Technology Group Practical Engineering Guidelines for Processing Plant the shell, depending on the type of reboiler The following design guidelines should be considered when the selection of a reboiler type is made. 1. Fouling -Tube-side is easier to clean than shell-side. 2. Corrosion – corrosion or process cleanliness may dictate the use

The domed top section of the reboiler separates the vapor and the liquid.LECTURE EIGHT 054410 PLANT DESIGN Kettle Reboiler In this type of thermosyphon reboiler circuit: Liquid flows from the column sump to the bottom of the kettle’s shell. The vapor flows back into the tower via the riser.

Sat, 08 Dec 2018 11:34:00 GMT reboiler kettle design pdf – Types of reboilers. The most critical element of reboiler design is the selection of the proper type

After describing the various types of evaporation “pool boiling, flow boiling, flash evaporation,” the different types of reboilers are introduced: vertical and horizontal thermosiphon reboiler, forced circulation reboiler, flash evaporation, kettle reboiler, internal evaporator, falling film evaporator. The design procedure for kettle-type reboiler and falling film evaporator is shown.

Heat Exchanger Type 8 (A) Shell & Tube Exchanger 8 (B) Plate Heat Exchangers 14 Figure 17: Kettle Reboiler 64 Figure 18: Recirculating Thermosyphon Reboiler on Column Bottoms 65 Figure 19: Once-Through Reboiler With Bottoms Tray Feed 65 Figure 20 : Pump Around Reboiler on Column Bottoms 66 Figure 21: Normal Crossflow Fraction 73 Figure 22 : Baffle Spacing Correction 74 Figure …

20/04/2018 · This is version 3.0 demonstration of Kettle Reboiler Design Software. This product allows you to do thermal analysis calculations for Kettle type reboilers. The software is …

27 replies on “Kettle type reboiler design pdf”

Leave a CommentThermosyphon reboiler dapat disusun secara horisontal ataupun vertikal, ini tergantung dari design prosesnya atau ketersediaan lahan. Reboiler type inipun …

Reboilers Kettle versus Thermosiphon Designs ULisboa

Free Kettle Reboiler Downloads

Co Author #03-12 Block Aronia REBOILER Jalan Sri Perkasa

maintenance design for distillation tower reboiler system. The thermosyphon reboiler contains the two The thermosyphon reboiler contains the two endearing qualities of the evaporator, namely mechanical simplicity and operation in the nucleate

Selection of Reboilers for Distillation Columns Gerard

Fractionation Research, Inc. RESEARCH – KEY TO BETTER DESIGN Hydraulics of Kettle-Reboiler Circuit on Distillation Columns Ton yy, , Cai, Mike Resetarits, and Ahmad Shariat

Selection of Reboilers for Distillation Columns Gerard

Types of reboilers. The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such reboilers.

Kettle Reboiler Heat Exchanger This software can make

reboiler design and operation to ensure proper venting, correct arrangement of steam traps on reboiler supply lines, compatibility of materials of construction, and impact of current system operation (i.e. dry, partially or totally flooded on the steam side).

Reboilers Kettle versus Thermosiphon Designs ULisboa

REBOILERS Thermopedia

4 Column-Base and Reboiler Arrangements

English: Cross-sectional diagram of an operating Kettle-type Reboiler used for industrial distillation towers. H Padleckas modified an image on November 4, 2006 originally created by User:mbeychok called “Kettle Reboiler.PNG” and uploaded to the English Wikipedia on November 2, 2006.

Distillation Ch4 Reboiler [PDF Document]

engineer thinks naturally in terms of the A sketches and

Kettle Reboiler Design Version 3.0 YouTube

Heat Exchanger Type 8 (A) Shell & Tube Exchanger 8 (B) Plate Heat Exchangers 14 Figure 17: Kettle Reboiler 64 Figure 18: Recirculating Thermosyphon Reboiler on Column Bottoms 65 Figure 19: Once-Through Reboiler With Bottoms Tray Feed 65 Figure 20 : Pump Around Reboiler on Column Bottoms 66 Figure 21: Normal Crossflow Fraction 73 Figure 22 : Baffle Spacing Correction 74 Figure …

Calculations download Kettle Reboiler Design – Thermal

Selection of Reboilers for Distillation Columns SlideShare

Steam reboiler system operations Revamp s

mixture of liquid components into two products using the heat provided by a kettle-type reboiler. Types of reboilers The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such reboilers. However, other heat transfer fluids

Shell Tube Heat Exchanger Kettle Reboiler Design (KRD

Publisher Description. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

Kettle Reboiler Design standaloneinstaller.com

Kettle Reboiler Design (KRD) FREE Download Kettle

Shell Tube Heat Exchanger Kettle Reboiler Design (KRD

There are generally Two type of reboiler used in industrial distillation column. Kettle type reboiler:- For the following condition we can use kettle type reboiler: Pressure drop in kettel type reboiler is lower so it is suitable for the Vacuum services. In kettle type reboiler liquid totally

Shell Tube Heat Exchanger Kettle Reboiler Design (KRD

Selection of Reboilers for Distillation Columns Gerard

Reboilers unipi.it

4 Column-Base and Reboiler Arrangements 4.1 INTRODUCTION t he design of a column base with its associated reboiler can be a comdex ~ â matter. It requires simultaneous consideration…

Design Of Kettle Reboilers Process Heat Transfer

Sat, 08 Dec 2018 11:34:00 GMT reboiler kettle design pdf – Types of reboilers. The most critical element of reboiler design is the selection of the proper type

“Managing Reboiler Steam-side Operation

Kettle Reboiler Design Version 3.0 YouTube

feeding the kettle reboiler. The kettle uses main column LCO pumparound heat between 450°F and 465°F, with the outlet temperature varying from 240–260°F. Throughout startup, there is little heat available from either debutanised gasoline or LCO pumparound due to low stream temperatures. As a result, the supplemental steam reboiler was added. While this is increasingly common, adding a

Hydraulics of Kettle-Reboiler Circuit on Distillation Columns

1 SCOPE This Process Engineering Guide is designed as an aid to the selection of reboilers for distillation columns. It describes the various options and details their merits and drawbacks. 2 FIELD OF APPLICATION This Guide is intended for process engineers and plant operating personnel in GBH Enterprises worldwide, who may be involved in the specification or design of reboilers. 3 …

Reboiler Selection Article CHEE10010 Chemical

Kettle Type Reboilers • Kettle reboilers, and other submerged bundle equipment, are essentially pool boiling devices, and their design is based on data for nucleate boiling.

Steam reboiler system operations Revamp s

GENERAL DESCRIPTION Kettle-Type Reboiler Heat Exchanger Model

4 Column-Base and Reboiler Arrangements 4.1 INTRODUCTION t he design of a column base with its associated reboiler can be a comdex ~ â matter. It requires simultaneous consideration…

Kettle Reboiler Design 1.0 Free download

Select the Right Reboiler Chemical Processing

KETTLE REBOILER HTRI

Reboilers provide vapor for a distillation tower. The most common type of reboiler is some variant of a shell-and-tube (S&T) exchanger — because such exchangers can satisfy a wide range of process and mechanical requirements at reasonable costs.

Design Of Kettle Reboilers Process Heat Transfer

Reboiler Selection Article CHEE10010 Chemical

engineer thinks naturally in terms of the A sketches and

Fractionation Research, Inc. RESEARCH – KEY TO BETTER DESIGN Hydraulics of Kettle-Reboiler Circuit on Distillation Columns Ton yy, , Cai, Mike Resetarits, and Ahmad Shariat

4 Column-Base and Reboiler Arrangements

Design of Kettle reboiler . NPTEL – Chemical Engineering – Chemical Engineering Design – II Joint initiative of IITs and IISc – Funded by MHRD Page 2 of 41 Lecture 1: Heat Exchangers Classifications 1. PROCESS DESIGN OF SHELL AND TUBE EXCHANGER FOR SINGLE PHASE HEAT TRANSFER 1.1. Classification of heat exchangers Transfer of heat from one fluid to another is an important …

Kettle Reboiler Design 1.0 Free download

Calculations download Kettle Reboiler Design – Thermal

chemE610, Kettle type reboiler is a type of shell and tube heat exchanger with differences in design basis some of which are as follows: 1) As a submerged bundle equipment, it’s a pool boiling device which has to be designed based on the data for nuclear boiling.

Steam reboiler system operations Revamp s

Kettle Reboiler Design (KRD) v.1.0 This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers.The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the

KETTLE TYPE REBOILER HEAT EXCHANGER YouTube

The domed top section of the reboiler separates the vapor and the liquid.LECTURE EIGHT 054410 PLANT DESIGN Kettle Reboiler In this type of thermosyphon reboiler circuit: Liquid flows from the column sump to the bottom of the kettle’s shell. The vapor flows back into the tower via the riser.

Kettle Reboiler Type Heat Exchanger Kettle Reboiler Type

What Is a Kettle Reboiler? wisegeek.com

Hydraulics of Kettle-Reboiler Circuit on Distillation Columns

Reboilers. UnitOperationsI ReboilerReboilerarrangements arrangements Forced-circulation Natural-circulation Once-through Recirculation. UnitOperationsI Forcedcirculationreboilers Predictablerecirculationrate High velocities Low percentagevaporisedper circulation Suitablefor: Viscousfluids Heavilyfoulingfluids Pumpingcosts Smallinstallations High pressuredrops(low …

Lecture 6 Condenser and Reboiler Design

Heat Exchanger Design Guide ScienceDirect

http://www.msubbu.in Ex-2 Kettle Type Reboiler It is required to design a kettle-type reboiler to vaporize 5000 kg/h of n-butane at 5.84 bar. The minimum temperature of feed will be 0 …

Selection of Reboilers for Distillation Columns SlideShare

GENERAL DESCRIPTION Kettle-Type Reboiler Heat Exchanger Model

maintenance design for distillation tower reboiler system. The thermosyphon reboiler contains the two The thermosyphon reboiler contains the two endearing qualities of the evaporator, namely mechanical simplicity and operation in the nucleate

(PDF) Criteria for the vapor space design in kettle reboilers

Design Of Kettle Reboilers Process Heat Transfer

Boiler thermal design calculations trend Double Pipe Heat

No hassle reboiler selection Reboiler selection guide eliminates the guesswork in choosing between a standard kettle type exchanger or a thermosyphon exchanger for reboiler applications D. L. Love, The Pro-Quip Corp, Tulsa, Okla. housing a reboiler design depends on several fac- tors: 1. Flow pattern of the feed and the percent vapor of the feed, 2. Viscosity of the feed and 3. Liq- uid level

Kettle Reboiler Design 1.0 Free download

KETTLE TYPE REBOILER HEAT EXCHANGER YouTube

288 Kettle-Type Reboiler, Heat Exchanger Model Product Dimensions (L x W x H) 27in. x 10in. x 15in. (700 x 250 x 375 mm) 10lbs. (6kg) Shipping Dimensions

Heat Exchanger Design Guide ScienceDirect

Kettle Reboiler Type Heat Exchanger Heat Exchanger

Comments are closed.