Boiler safety valve setting pdf

Depending upon the design pressure of boiler, the various safety valves in the boiler are set to open at a particular pressure called the “set pressure.” Until the system pressure reaches the set pressure, the valve will not open or leak.

1 1 Overall information 1.1 Overall View Fan Safety thermostat Burner Ignition electrodes Gas valve Control panel Automatic air purger Pump D.h.w. temp. probe D.h.w.

The discharge capacity of a safety valve must be equal to or greater than the output of the boiler or system it is protecting. To ensure To ensure that the correct method of sizing is used, reference should be made to the relevant BS specification for the design of the boiler or

Boiler with super heater, normally three safety valves are fitted; two to the boiler drum and one to the superheater. The superheater must be set to lift first to ensure a flow of steam through the superheater.

The boiler’s safety or relief valves are designed to help protect the boiler from damage should an over pressure condition develop. But, the first line of defense is the company’s inspection activities to ensure the boiler and its component parts

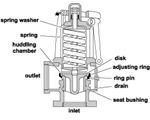

In the case of adjusting the spring type of relief valve, usually there is a screw adjustment at the top of the safety valve allowing the spring to be either compressed to exert more pressure on the ball and hence inside the boiler, or released to allow the boiler pressure to be maintained at a lower level.

Boiler Safety compliance oiler is an important utility in factories. It is used to generate steam. The generated steam is distributed through pipes to feed various equipment in the factory. Poorly maintained boilers can be a potential source of serious accidents. There are several examples of boiler explosion and loss of lives and assets. In a recent boiler explosion in a South Asian country

Design and Setting of the Marine Boiler Safety Valve. Safety valves are fitted to protect the boiler from the effect of over pressure. At least two safety valves are fitted to each boiler steam drum, but if there is a super heater, another safety valve should be fitted on it.

pressure of not less than the safety valve setting of the boiler but never less than 100 PSI. (B31.1 Para. 122.1.2). 2. Each Boiler must be fitted with a steam stop valve located at an accessible point in the steam-delivery line and as near the boiler nozzle outlet as is convenient and practical. (B31.1 Para. 122.1.7). A check valve is normally recommended installed close to the outlet of the

Boiler Safety Valves protect the boiler from over pressurisation. As per the requirements, at least two safety valves should be fitted to the boiler and both are mounted on a common manifold with a single connection to the boiler.

The pressure at which safety valve just opens is known as the set pressure of safety valve and it is set at the pressure not exceeding 3% above the working pressure of boiler for marine boilers. The safety valve will close once the system pressure reduces to reset pressure.

23/07/2013 · On the boiler the safety valve and its components will all have expanded with the temperature, and different components have different co-efficients of thermal expansion, so a hot safety valve will not lift at the same pressure as a cold one.

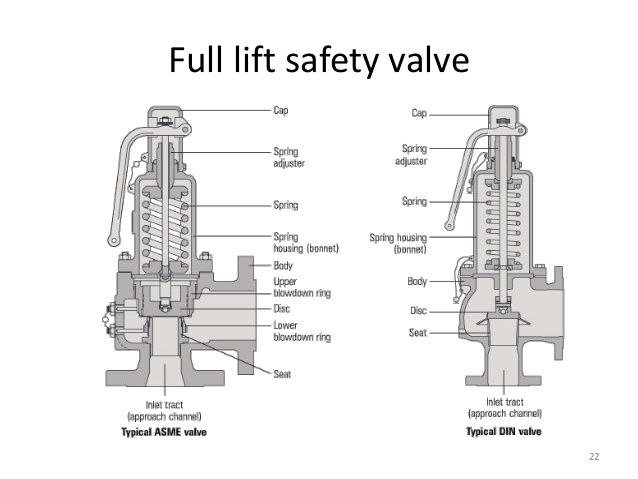

D. Safety Valve: A pressure relief ANDERSON GREENWOOD CROSBY • TECHNICAL SEMINAR MANUAL 4©2001 Tyco Valves & Controls There are two kinds of direct-acting type PRVs, weight- loaded and spring-loaded. Weight-Loaded The direct-acting, weight-loaded PRV was the first type of PRV to be used. They were employed to protect steam boilers from overpressure. The design of these …

17/05/2011 · The pressure setting of the superheater safety valve should be less that the designed pressure of the boiler, i.e. less than that of the steam drum safety valve, to ensure flow of steam through the superheater under blow off conditions. The pressure setting of one steam drum safety valve should be same as the design pressure of the boiler. The pressure setting of another safety valve …

Usually for High pressure Boiler , on its steam drum , two safety valves are placed. But of different pressure setting. Suppose the working pressure is 60 kg/cm2, then one safety valve will be set at around 65 kg/cm2 and the other one at 67.5 kg/cm2.

Installation Operation Service Manual Bryan Steam

boiler safety valve setting Archives Marine Engineering

published and continues to update the Boiler and Pressure Vessel codes for safety valves. It is the responsibility of plant personnel—primarily the plant’s steam team—to know which codes apply to the different parts of the steam system. 2. SIZING GUIDELINES FOR SAFETY VALVES The set point for the safety valve shall be at least 10% between the operating system pressure and the safety

The pressure existing at the outlet of a safety relief valve caused by flow through the valve into the disposal system. Differential Set Pressure This is the difference between the set …

For each boiler, one (1) or more safety valves on the boiler shall be set at or below the maximum allowable working pressure. If additional valves are used, the highest pressure setting shall not exceed the maximum allowable working pressure by more than three (3) percent.

If existing, open the heating supply valve and the heating return valve. If existing, open the cold water valve and the DHW valve. When using ZBR..-3A appliances with …

Fig 542 APPLICATIONS The Fig 542 Safety Valve is an extremely versatile valve, suitable for use on hot water, steam or air. Although designed primarily for the protection of hot water boilers, it’s wide range of applicants make it an ideal valve for stocking as a general purpose safety valve. CONSTRUCTION The Fig 542 is of gunmetal construction, with diaphragm protected working parts …

Talk to the experts. NABIC has a rich history dating back to the Industrial Revolution and Victorian Age and is a brand name you can trust. We manufacture in the UK a range of safety and pressure relief valves as well as control valves in gunmetal and stainless steel suitable for a wide variety of fluids including steam, hot water and air.

Pressure Safety valve or PSV Valve is the most important valve on a boiler used to relief excess pressure to atmosphere let’s see how psv valve is important, Let’s discuss about Pressure safety valve theory installation rules and PSV valve mechanism, Sv setting, testing and the types.

safety, the National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation , and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulations .

Traditionally the safety valves downstream of the boiler (or drum) will be set to lift at a lower pressure than those on the boiler/drum. This is to allow continued steam flow through the superheater and other piping for cooling.

Boiler safety valves are installed in pairs with one valve set at a little higher pressure to ensure boiler does not explode of overpressure in the event of failure of any one boiler safety valve. 4) Boiler level gauge glass : Boiler gauge glasses are fitted in pairs for manually checking the water level inside the boiler …

A boiler safety valve is a spring loaded valve, which is always fitted in pairs on a common valve chest. The valve is so set that it releases all the steam generated by the boiler if the boiler pressure increases 10% above the pre-set level. The main advantage of a boiler safety valve is that it is the utmost form of reliable safety measure that a boiler can have, and which also shows positive

12/05/2018 · This video from Thermodyne Engineering Systems, explains- How you can set the Safety Valve Pressure in a Boiler and open the Safety valve to understand its parts & Safety Valve, Working.

Safety unit with straight body for water heater, complete with safety valve, shut-off valve (to isolate the water heater from the supply line), inspectable check valve (to prevent return of contaminated water in the supply line), lever for manual discharge via the safety valve.

T&P and ASME Safety Relief Valves Watts Water

In connection with the superheater, the safety valves on the boiler drum are to be set at a pressure not less than the superheater-valve setting plus 0.34 bar (0.35 kgf/cm 2, 5 psi), plus approximately the normal-load pressure drop through the superheater.

safety valve and a relief valve and may be used in either application. Temperature and Pressure Safety Relief Valve – This device is typically used on potable water heaters.

the boiler at a pressure of three (3) percent higher than the highest setting of any safety valve on the boiler. 018. Power boilers fired by gaseous, liquid, or solid fuel in suspension may be equipped with a single means of feeding water provided means are furnished for the immediate shutoff of heat input prior to the water level reaching the lowest permissible level. The feed-water shall be

Boiler safety valve setting detailed calculation – 10-10-2010, 15:57 Boiler safety valve is set to lift at any pressure, but not more than 3% above working pressure. Also the safety Valve re-sits at 5% below working pressure.

1 General safety instructions and explanation of symbols 3 1.1 Explanation of symbols 3 1.2 Safety instructions 3 2 Product description 4 2.1 Intended use 4 2.2 Certification and testing mark 4 2.3 Disposal 4 2.4 Product description 4 3 Commissioning the heating system 5 3.1 Turning the heating system on 5 3.2 Checking the operating pressure, topping up the boiler water and bleeding air from

Superheated steam safety valves should be set as close to operating temperature as possible as expansion can alter the relationships between valve trim and guide/nozzle rings which can effect the correct operation of the valve.

WRITEUP ON SAFETY VALVE & ERV OF POWER PLANT Download as PDF, TXT or read online from Scribd

OBSERVING BOILER SAFETY RULES The rules that follow are brief reminders of the possible consequences in a boiler plant of inappropriate operator response or questionable action in maintaining the boiler …

and the safety relief valve setting for high-temperature water boilers be selected substantially higher than the desired operating pressure so as to minimize the times the safety relief valve must lift.

The pressure at which safety valve just opens is known as the set pressure of safety valve and it is set at the pressure not exceeding 3% above the working pressure of boiler for marine boilers. – electro steam model lg boiler manual (2) The final setting of boiler safety valves shall be checked and adjusted under steam pressure and, if possible, while the boiler is on the line and the steam is at operating temperatures, in the presence of and to the satisfaction of a marine inspector who, upon acceptance, shall seal the valves.

In case of economiser safety valves the valves are set by the chief engineer at sea and the surveyor is informed. Safety valves are provided to prevent over pressurisation of the boiler, which would cause it to explode and can be harmful and fatal for personnel. Easing gear is fitted basically to allow for manual operation of the safety valve, in case of failure to open when the boiler has

Pressure increase over the set pressure, at which the safety valve attains the lift specified by the manufacturer, usually expressed as a percentage of the set pressure. It is the overpressure used to certify the safety valve. Relieving pressure (p1) Pressure used for the sizing of a safety valve which is greater than or equal to the set pressure plus overpressure. Lift Actual travel of the

Under no circumstances should the relief valve setting of the valve exceed the working pressure of the tank, as this would violate all heater warranties and codes.

The safety v/v must be set at a pressure not exceeding 3% of the approved boiler working pressure. It is normal to set the suphtr safety below that of the drum to ensure an adequate flow of stm for cooling purposes under fault conditions. Similarly the superheater should be set to close last.

That means safety valve is set correctly and working. Maximum permissible working pressure can be obtained from the Certificate of Fitness. (d) If the safety valve does not open when the steam pressure reaches the m.p.w.p., boiler should be stopped immediately, and the easing gear operated to release steam and lower the boiler pressure. Call the Appointed Examiner for examination immediately

open the valve to atmos phere, thus reducing pressure and balancing the boiler operation. When When the preset low pressure is reached, the controller signals the actuator to close the valve.

24/01/2007 · Boiler Set Sizing RHO SHO Drum Total Relieving Capacity of all Code valves must be RHI equal to or greater than the maximum continuous rating

However, the range of the setting of all the safety valves on the boiler should not exceed 10% of the highest pressure to which any valve is set. Each safety valve should reseat tightly with a blowdown of not more than 2 psig or 4% of the valve setting, whichever is greater.

Valve Opening. In an upset situation a safety valve will open at a predetermined set pressure. The spring force F s is acting in closing direction and F p, the force created by the pressure at the inlet of the safety valve, is acting in opening direction.

For valves set above 100 psig, blowdown shall be between 2% and 4%. For valves set at or below 100 psig, blowdown shall be between 2 and 4 psi. Single Valve Multiple Valves Superheater Reheater Boilers less than 500 sq. ft. heating surface and generates less than 4000#/hr. (PG-67.1) At least one valve must be set at or below the design pressure. At least one valve shall be installed on the

the boiler to the set pressure of the relief valve. The relief valve will discharge, so that the boiler will not be able to generate pressure

Then set the superheater safety valve lower than the designed pressure of the boiler in same procedure. Then screw down all the safety valves higher than the setting pressure at which you are going to set. 7. Recheck the setting pressure and gag the valve.4. when it blows off at designed pressure then note this opening pressure and check the closing pressure also. 8. . Pressure setting should

Safety valves fitted into boiler. It is important that the Boiler Operator have a thorough knowledge and understanding of the purpose of the following valves, controls and fittings, as required on steam boilers:

Marine Boiler Safety Valve Checks Overhaul and Settings

Boiler_Safety_valves.pdf Valve es.scribd.com

Selection and Sizing of Pressure Relief Valves PDHonline.com

Neb. Rev. Stat. John A. Gale

EXCERPTS FROM ASME CODE TUBACERO

FIG 542 SAFETY RELIEF VALVE Nabic Valves Online

Residential Gas Condensing Boiler Greenstar

Boiler Mountings marineengineering.org.uk

weil mclain gold oil boiler model wgo 3 installtion manual 2019 – Boiler Mountings A Comprehensive List Marine Insight

Model Steam Safety Valves Relief Valves

CoC Oral Exam Preparation (Part – 17) Boiler Safety Valve

Boiler Safety Valve Setting Boiler Pressure Thermodyne

11 replies on “Boiler safety valve setting pdf”

Leave a CommentFig 542 APPLICATIONS The Fig 542 Safety Valve is an extremely versatile valve, suitable for use on hot water, steam or air. Although designed primarily for the protection of hot water boilers, it’s wide range of applicants make it an ideal valve for stocking as a general purpose safety valve. CONSTRUCTION The Fig 542 is of gunmetal construction, with diaphragm protected working parts …

Boiler Mountings marineengineering.org.uk

24/01/2007 · Boiler Set Sizing RHO SHO Drum Total Relieving Capacity of all Code valves must be RHI equal to or greater than the maximum continuous rating

Boiler operation control

Safety valves fitted into boiler. It is important that the Boiler Operator have a thorough knowledge and understanding of the purpose of the following valves, controls and fittings, as required on steam boilers:

marine boiler safety valve blackhatmarine

CoC Oral Exam Preparation (Part – 17) Boiler Safety Valve

That means safety valve is set correctly and working. Maximum permissible working pressure can be obtained from the Certificate of Fitness. (d) If the safety valve does not open when the steam pressure reaches the m.p.w.p., boiler should be stopped immediately, and the easing gear operated to release steam and lower the boiler pressure. Call the Appointed Examiner for examination immediately

46 CFR 52.01-120 Safety valves and safety relief valves

Boiler with super heater, normally three safety valves are fitted; two to the boiler drum and one to the superheater. The superheater must be set to lift first to ensure a flow of steam through the superheater.

Design and Setting of the Marine Boiler Safety Valve

POWER BOILERS ASME SECT. I & POWER PIPING ANSI/ASME B

Marine Boiler Safety Valve Checks Overhaul and Settings

(2) The final setting of boiler safety valves shall be checked and adjusted under steam pressure and, if possible, while the boiler is on the line and the steam is at operating temperatures, in the presence of and to the satisfaction of a marine inspector who, upon acceptance, shall seal the valves.

Safety Valve Setting Boiler scribd.com

Boiler Safety compliance oiler is an important utility in factories. It is used to generate steam. The generated steam is distributed through pipes to feed various equipment in the factory. Poorly maintained boilers can be a potential source of serious accidents. There are several examples of boiler explosion and loss of lives and assets. In a recent boiler explosion in a South Asian country

Boiler Safety Valve Setting Boiler Pressure Thermodyne

Depending upon the design pressure of boiler, the various safety valves in the boiler are set to open at a particular pressure called the “set pressure.” Until the system pressure reaches the set pressure, the valve will not open or leak.

Residential Gas Condensing Boiler Greenstar

Pressure Safety valve or PSV Valve is the most important valve on a boiler used to relief excess pressure to atmosphere let’s see how psv valve is important, Let’s discuss about Pressure safety valve theory installation rules and PSV valve mechanism, Sv setting, testing and the types.

marine boiler safety valve blackhatmarine

Section I Boiler Safety Valve Sizing & SelectionSizing

WRITEUP ON SAFETY VALVE & ERV Valve Boiler

Pressure increase over the set pressure, at which the safety valve attains the lift specified by the manufacturer, usually expressed as a percentage of the set pressure. It is the overpressure used to certify the safety valve. Relieving pressure (p1) Pressure used for the sizing of a safety valve which is greater than or equal to the set pressure plus overpressure. Lift Actual travel of the

Pressure safety valve theory and PSV valve mechanism

D. Safety Valve: A pressure relief ANDERSON GREENWOOD CROSBY • TECHNICAL SEMINAR MANUAL 4©2001 Tyco Valves & Controls There are two kinds of direct-acting type PRVs, weight- loaded and spring-loaded. Weight-Loaded The direct-acting, weight-loaded PRV was the first type of PRV to be used. They were employed to protect steam boilers from overpressure. The design of these …

PROPER SIZING AND INSTALLATION FOR STEAM SYSTEM SAFETY VALVES

marine boiler safety valve blackhatmarine

Design and Setting of the Marine Boiler Safety Valve

Comments are closed.