Circulating fluidized bed boiler pdf

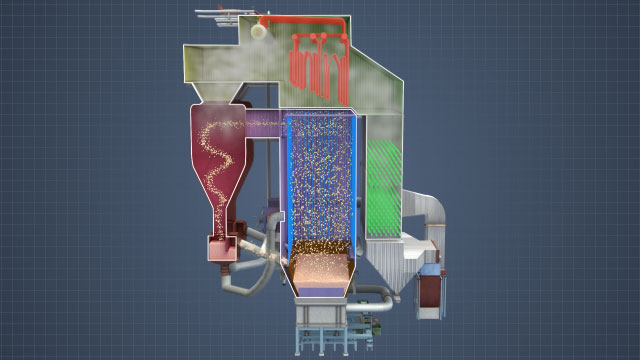

CYMIC is an advanced circulating fluidized bed (CFB) boiler developed by Valmet. It combines high-efficiency combustion of various solid fuels with low emissions, even when burning fuels with completely different calorific values at the same time.

Comprehensive Simulator (CSFMB) Applied to Circulating Fluidized Bed Boilers and Gasifiers Marcio L. de Souza-Santos* University of Campinas (UNICAMP), Faculty of Mechanical Engineering, Department of Energy, CP 6122, Campinas, SP 13083-970, Brazil Abstract: A comprehensive simulation program of bubbling fluidized beds (CSFB or CSFMB) has been able to repro-duce operations of circulating

2 The quality is the test of the character . It is our mission to satisfy our customers. DHX series circulating fluidized bed boiler absorbs the advantages of circulating fluidized bed boiler both at home and abroad,

coal-fired circulating fluidized-bed boiler, based on hydrodynamics, heat transfer and combustion, is presented. This model predicts the flue gas temperature, the chemical

circulating fluidized-bed boilers involves a two-stage combustion process: the reducing combustion at the fluidized-bed section, and the oxidizing combustion at the freeboard section.

Towards Better Understanding of Circulating Fluidized Bed Boilers: A Data Mining Approach Mykola Pechenizkiy 1, Antti Tourunen 2, Tommi Kärkkäinen 1,

There are two main types of fluidised bed combustion boilers: Bubbling fluidized bed (BFB) and circulating fluidised bed (CFB) boilers. In the bubbling type, because the velocity of the air is low, the medium particles are not carried

vertical circulating fluidized bed (VCFB) boiler was developed (Yue et al., 2005). Due to the fuel flexibility, Due to the fuel flexibility, circulating fluidized bed combustion has proven to be effective way of converting biomass wastes into clean

The feedstock, as well as the bed material, has a wide size distribution in CFB boilers. As shown in Fig. 1, the flow pattern in the furnace is composed of the bubbling or turbulent bed formed by

“ (FBC) Fluidized bed combustion is a combustion technology used to burn solid fuels in steam boilers.” In Fluidized Bed Combustion Boiler technology When air or gas is passed through an inert bed of solid particles such as sand supported on a fine mesh or grid, the air initially will seek a path of least resistance and pass upward through the sand. With …

fluidized bed boiler design and retrofits Challenges Today the goals typically are to meet new emission limits and to replace fossil fuels by bio fuels and waste. The increasing use of low quality fuels sets high demands on the understanding and control of the furnace processes in order to ensure satisfactory operation and furnace availability. Increasing use of renewable energy sources with

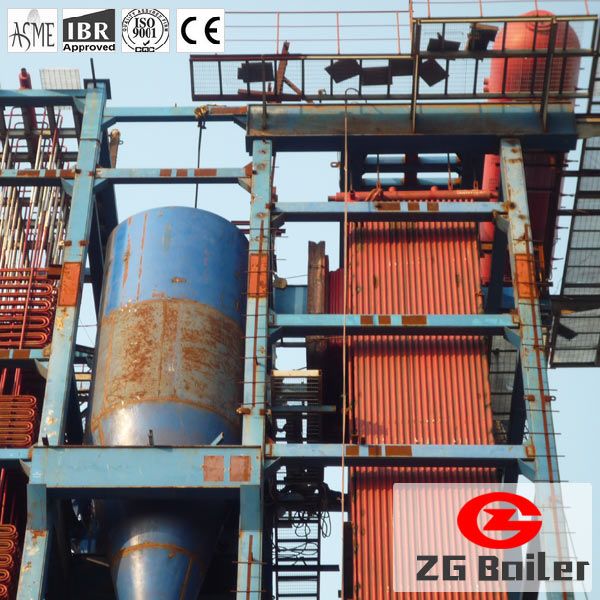

280 ton CFB boiler for Metallurgical Plant When the ZG power plant began commercial operations in late June 2009, it marked a new era in the evolution of circulating fluidized bed (CFB) technology. At the heart of the 460 megawatt electric (MWe) ZG power plant is the worldâs largest CFB boiler, which is also the worldâs first once-through unit (OTU) supercritical CFB boiler. Large enough to

Circulating Fluidized Bed Boiler Design: Gain a thorough understanding of the best design methods of circulating fluidized bed boilers. Design of Circulating Fluidized Bed Boiler Components and Systems : Learn all the techniques used to design CFB boiler equipment and systems including furnace, cyclones, economizers, superheaters, reheaters, loop seals, expansion joints, refractory, …

A circulating fluidized bed boiler including a furnace, a separator which is connected to the furnace to separate fluidized bed material from a flow leaving the furnace, as well as a return duct between the separator and the furnace to return the separated fluidized bed material into the furnace.

3 The quality is the test of the character . It is our mission to satisfy our customers. Parameters Circulating Fluidized Bed Power Plant Boiler

Overview of Wear Problems in Circulating Fluidized Bed Boilers

Circulating Fluidized Bed Boiler Industrial BoilerOil

IEA Clean Coal Centre– Operating experience of low grade fuels in circulating fluidised bed combustion (CFBC) boilers 3 Preface This report has been produced by IEA Clean Coal Centre and is based on a survey and analysis of published

NORMAL OPERATION • • • • • • Bed temperature The SO2 emissions the fluidized beds for even fluidization the fluidized bed level Water Chemistry and Steam Purity SootBlowing . leave the FD and ID fans in operation for at least five minutes to purge boiler.

Abstract: The key driver for choosing a Circulating Fluidized Bed (CFB) Boiler is the ability to burn a wide range of fuels with highly efficient combustion while meeting low emission requirements. Reduced sorbent and water consumption compared with Pulverized Coal (PC) plants and the ability to

The circulating fluidized bed boiler, as in one of claims 3-7, wherein said film divider is formed at said separator space at a position according to a need of said boiler, wherein said film divider is provided at one of positions that said film divider is provided at the middle of said rear wall of said boiler furnace and said front wall of the vertical tunnel, said film divider is located

THERMAL ENGINEERING Vol. 54 No. 6 2007 CIRCULATING FLUIDIZED BED BOILERS ABROAD 503 heat exchangers. Anthracite will be used as fuel. The minimum load of the boiler …

Circulating Fluidized Bed (CFD) is a process of providing boilers and power plants maximum flexibility in burning variety of fuels. The CFB boilers market has seen a significant growth over the past three years due to increased need for power.

DESIGN OF CIRCULATING FLUIDIZED BED BOILERS 09 -11 MAY 2018, MANILA, PHILIPPINES www.poweredgeasia.com joints, refractory, and L Several studies have confirmed that CFB boilers are the best method for power generation.

The circulating fluidized bed (CFB) is a developing technology for coal combustion to achieve lower emission of pollutants. By using this technology, up to 95% of pollutants can be absorbed before being emitted to the atmosphere. Introduction. Circulating fluidized bed is a relatively new technology with the ability to achieve lower emission of pollutants. Extensive research has been conducted

top o the fluid bed reactor results in a “circulating fluid bed” reactor, because the largest particles carried out by gas flow of the reactor are separated from the flue gas and returned back to the reactor.

POWERFLUID circulating fluidized bed boilers are used for steam and power generation from coal and biomass – and for co-incineration and incineration of …

A steady state model of a coal-fired circulating fluidized-bed boiler, based on hydrodynamics, heat transfer and combustion, is presented. This model predicts the flue gas temperature, the chemical gas species (O 2, H 2 O, CO, CO 2 and SO 2) and char concentration distributions in both the axial and radial locations along the furnace including

Abstract−The performance of a commercial circulating fluidized bed boiler in the Yeosu thermal power plant, which has been operating since October 2011 by KOSEP, has been evaluated by using the IEA-CFBC model.

Furnace Design of 210 MW Circulating Fluidized Bed Boiler-Numerical Investigation, International Journal of Mechanical Engineering and Technology , 8(3), 2017, pp. 442– 455.

Basu has been associated with the development of fluidized bed boilers in industry, government laboratories and universities since 1972. His research at TUNS and Dalhousie University on circulating fluidized bed has allowed him to consult for boiler and energy companies in …

The Coordinated Control of Circulating Fluidized Bed Boiler with Intelligence Feedforward Control Xiao-Feng Li, Shi-He Chen, Qing Zhong *Guangdong Power Test and Research Institute.

Performance Analysis of 250 MW Lignite Fired Circulating Fluidized Bed 79 Fig.3 Heat losses and efficiency of CFBC boiler In this special type of boiler there are heat credits apart from heat losses.

patentsaler t ix 5513488 5513599 power process ut il iz ing humidif ied combusted a ir to gas turbine pressurized internal c irculat ing fluid ized-bed boiler fan zhen parsippany,…

The regions CIRCULATING FLUIDIZED BED COMBUSTION BOILER AND VARIANTS IN are high velocity combustion region, low velocity heat transfer region and medium velocity suspension region. The differential velocity CFBC combustor improves the efficiency of the combustion. Circulation of bed material is by discrepancy of entrainment at differential air velocity. The velocity is in the order of 3 …

FURNACE DESIGN OF 210 MW CIRCULATING FLUIDIZED BED BOILER

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels. In its most basic form, fuel particles are suspended in a hot, bubbling fluidity bed of ash and other particulate materials (sand, limestone etc.) through which jets of air are blown …

ABSTRACT: A Circulating Fluidized Bed Combustor (CFBC) is a highly efficient combustor. It can handle It can handle various types of solid fuels such as coal, biomass or agricultural wastes.

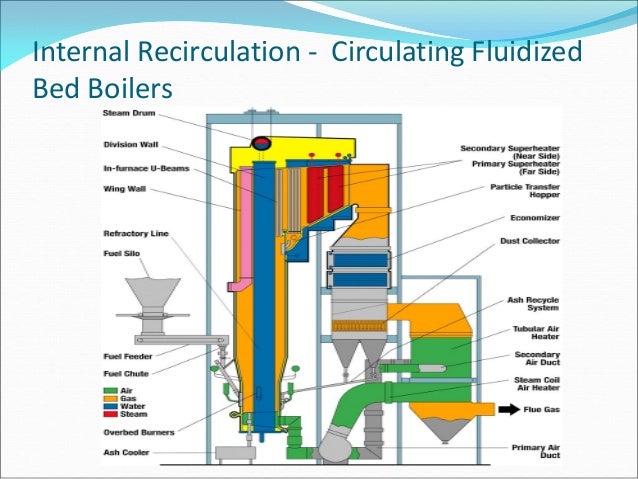

Internal Circulating Fluidized-bed Combustion Technology (ICFBC) For the fluidized-bed boiler, desulfurization takes place mainly in the furnace. However, ICFBC does not have a heat transfer tube in the fluidizing section, so the boiler does not cause wear on the heat transfer tube in the bed. Because of this, silica sand can be used as the fluidizing material for ICFBC, instead of soft

157 Overview of Wear Problems in Circulating Fluidized Bed Boilers Jelena Priss, Ivan Klevtsov Tallinn University of Technology jelenapriss@gmail.com

Care and Maintenance of Circulating Fluidized Bed Boilers Among the numerous maintenance items encountered with the operation of circulating fluidized bed boilers refractory failure may be the most problematic, time consuming, and costly. Refractory used in circulating fluidized bed boilers includes brick, block, tile, plastic rammed, castable and “gunned” refractory. Two of the most – wordpress plugin boilerplate tutorial Karppanen, Erkki, Advanced control of an industrial circulating fluidized bed boiler using fuzzy logic Department of Process Engineering, University of Oulu, FIN-90570 Oulu, Finland

circulation fluidised bed (CFB) boiler equipped for research purposes but also in a full- scale CFB boiler. The results were evaluated by means of IACM (on-line measurements

The conditions for CO 2 reduction in a circulating fluidized bed (CFB) oxy-boiler are studied, that is, operation with pure oxygen, diluted by recirculated flue gases to moderate the combustion process.

STUDY OF CIRCULATING COAL FLUIDIZED BOILERS Sugato hajra1, the boiler and the bed particles are re-circulated to the combustion chamber through fluidised bed heat exchangers. There are four such fluidised bed heat exchangers namely Super heater I, super heater II, evaporator, and reheater. The combustion chamber is enclosed with water-cooled tubes and a gas-tight membrane. …

coal-fired circulating fluidized-bed boiler, based on hydrodynamics, heat transfer and combustion, is presented. This model predicts the flue gas temperature, the chemical gas species (O 2, H 2 O, CO, CO 2 and SO 2) and char concentration distributions in both the axial and radial locations along the furnace including the bottom and upper portion. The model was validated against experimental

Composition of Oil Shale Ashes from Pulverized Firing and Circulating Fluidized-Bed Boiler… 341 November the 5th, 2008. According to the information from the Narva TPPs,

Transients in a circulating fluidized bed boiler firing biomass are considered. An attempt is made to describe transients with the use of concepts applied in the automatic control theory. The parameters calculated from an analysis of unsteady heat balance equations are compared with the experimental

Combustion Power entered this market with a hybrid circulating fluidized bed boiler. The system The system uses the positive attributes of a bubbling/turbulent bed combined with a bed-solids circulating

· Explains operation and scientific fundamentals of circulating fluidized bed (CFB) boilers· Outlines practical issues in industrial use· Teaches how to optimize design for maximum reliability and efficiency · Discusses operating and maintenance issues and how to troubleshoot them This book

Characterization of 30 MW th Circulating Fluidized Bed Boiler under Oxy‐Combustion Conditions 3rd Oxyfuel Combustion Conference, September 10 ± 13, 2013

Circulating Fluidized Bed Combustion (CFBC) boiler, unaware of the existing patents and without applying for own patents. He became inspired by a lecture of Prof. Arthur Squires at Stockholm and by experience as supplier of classical roaster boiler equipment for Lurgi in Finland. In 1979 they were the first company to start up a plant with 15 MWth to burn bark, wood waste and coal (Suomen

Fluidized bed-combustion features a) direct contact of particles withintensivemass and heat exchange, b) uniform temperature in the fluidized bed c) high heat capacity of fluidized bed makingitpossible to burn fuels of low quality, wet and with high content of ash d) effectiveness of bed temperature control by supply of fuel, air and heat extraction. COMBUSTION AND FUELS Major features of

6. FBC Boilers 6. FBC BOILERS Syllabus The fluidized bed boilers have a wide capacity range- 0.5 T/hr to over 100 T/hr. 6.2 Mechanism of Fluidised Bed Combustion When an evenly distributed air or gas is passed upward through a finely divided bed of solid particles such as sand supported on a fine mesh, the particles are undisturbed at low velocity. As air velocity is gradually increased, a

(PDF) Design Theory of Circulating Fluidized Bed Boilers

PDF. About this book. Introduction · Explains operation and scientific fundamentals of circulating fluidized bed (CFB) boilers · Outlines practical issues in industrial use · Teaches how to optimize design for maximum reliability and efficiency · Discusses operating and maintenance issues and how to troubleshoot them . This book provides practicing engineers and students with insight into

Global circulating fluidized bed (CFB) boilers market has experienced a steady growth over recent years and is expected to witness significant expansion over next seven years owing to growing concern over strict adherence to toxic standards and policies.

CHARACTERISTICS OF THE INTERNALLY CIRCULATING FLUIDIZED BED BOILER T. HIROTA, T. OHSHITA, S. KOSUGI, S. NAGATO, T. HIGO, AND N. INUMARU Plant Engineering Division

Circulating Fluidized Bed Boilers 3 Circulating Fluidized Bed Boilers Product Evolution 1978: The first fluidized bed boiler became operational

Heat Transfer in Circulating Fluidized Bed Pavel Rusheljuk Tallinn University of Technology Abstract Heat transfer in the circulating fluidized bed is, apart from the particle and gas mixing, the most important process contributing to the intensity of the physical and chemical processes. In fact, several different processes can be distinguished: particle-gas heat transfer, heat transfer

Studies on circulating fluidized bed (CFB) boilers have being conducted at the Tsinghua University (TH) for about two decades and much of works are done to link the fundamentals with practical

fluidized bed boiler, fluidized air supply system, start-up burners, lower and upper overfire air supply system, fuel fill chute, sand fill chute, bubble caps (spargers), economizer and steam drum. At the beginning, fluidized air should be send into boiler through bubble caps, and the sands, limestone

Circulating Fluidized Bed Boilers – Design & Operations, Butterworths, Stoneham, USA, 1991 [PDF – 11 MB] Circulating Fluidized Bed Boiler (In Chinese language) Science Press, Beijing, China, 1995 [PDF …

The Coordinated Control of Circulating Fluidized Bed

Circulating Fluidized Bed Boilers Furnace Boiler

Salah satu boiler yang dibedakan atas jenis-jenis sistem pembakarannya adalah Circulating Fluidized Bed Boiler. )8( Circulating Fluidized Bed Boiler )8( Circulating Fluidized Bed Boiler Boiler CFB adalah boiler stoker (unggun fluidisasi) dimana batu bara dibakar diatas rantai berjalan (Belt Con eyor) dan diberi hembusan udara dari sisi ba!ah sehingga batu bara membara diatas rantai berjalan

Pulverized combustion vs Circulating Fluidized Bed combustion boiler efficiency comparison Pavel Rusheljuk Tallinn University of Technology Pavel.Ruseljuk@nj.energia.ee Abstract The thermal efficiency of steam generators can be usually determined using the Input-output method (efficiency is determined as the ratio of heat absorbed by the working fluids) and Heat loss method (determination …

Circulating Fluidized Bed Combustion System (CFBC) Due to the presence of shortcomings in traditional bubbling bed combustion, it is the need of time to develop

Computational Fluid Dynamics (CFD) for fluidized bed

Pulverized combustion vs Circulating Fluidized Bed

6. FBC BOILERS EM & EA

STUDY OF CIRCULATING COAL FLUIDIZED BOILERS

(PDF) Design theory of circulating fluidized bed boilers

– US20120240870A1 Circulating fluidized bed boiler with

Simulation of a Circulating Fluidized Bed Combustor with

COMMERCIAL APPLICATION OF WASTE-FUEL FIRED HYBRID

Evaluation of the performance of a commercial circulating

33 replies on “Circulating fluidized bed boiler pdf”

Leave a CommentNORMAL OPERATION • • • • • • Bed temperature The SO2 emissions the fluidized beds for even fluidization the fluidized bed level Water Chemistry and Steam Purity SootBlowing . leave the FD and ID fans in operation for at least five minutes to purge boiler.

COMPOSITION OF OIL SHALE ASHES FROM PULVERIZED FIRING AND

Computational Fluid Dynamics (CFD) for fluidized bed

Heat Transfer in Circulating Fluidized Bed Pavel Rusheljuk Tallinn University of Technology Abstract Heat transfer in the circulating fluidized bed is, apart from the particle and gas mixing, the most important process contributing to the intensity of the physical and chemical processes. In fact, several different processes can be distinguished: particle-gas heat transfer, heat transfer

Oxy-fuel combustion in circulating fluidized bed boilers

The circulating fluidized bed (CFB) is a developing technology for coal combustion to achieve lower emission of pollutants. By using this technology, up to 95% of pollutants can be absorbed before being emitted to the atmosphere. Introduction. Circulating fluidized bed is a relatively new technology with the ability to achieve lower emission of pollutants. Extensive research has been conducted

6. FBC BOILERS EM & EA

(PDF) Design Theory of Circulating Fluidized Bed Boilers

Pulverized combustion vs Circulating Fluidized Bed

Furnace Design of 210 MW Circulating Fluidized Bed Boiler-Numerical Investigation, International Journal of Mechanical Engineering and Technology , 8(3), 2017, pp. 442– 455.

Characterization of 30 MWth Circulating Fluidized Bed

ACHIEVABLE COMBUSTION EFFICIENCY with ALSTOM CFB BOILERS

Circulating Fluidized Bed Boilers 3 Circulating Fluidized Bed Boilers Product Evolution 1978: The first fluidized bed boiler became operational

Evaluation of the performance of a commercial circulating

ABSTRACT: A Circulating Fluidized Bed Combustor (CFBC) is a highly efficient combustor. It can handle It can handle various types of solid fuels such as coal, biomass or agricultural wastes.

Performance Analysis of 250 MW Lignite Fired Circulating

Open Access Comprehensive Simulator (CSFMB) Applied to

circulation fluidised bed (CFB) boiler equipped for research purposes but also in a full- scale CFB boiler. The results were evaluated by means of IACM (on-line measurements

Circulating Fluidized Bed Boilers Abroad Springer

Heat Transfer in Circulating Fluidized Bed ttu.ee

Basu has been associated with the development of fluidized bed boilers in industry, government laboratories and universities since 1972. His research at TUNS and Dalhousie University on circulating fluidized bed has allowed him to consult for boiler and energy companies in …

Brief Introduction of Fluidized Bed Boiler

Fluidized Bed Combustion FBC Boiler boilersinfo.com

US20120240870A1 Circulating fluidized bed boiler with

· Explains operation and scientific fundamentals of circulating fluidized bed (CFB) boilers· Outlines practical issues in industrial use· Teaches how to optimize design for maximum reliability and efficiency · Discusses operating and maintenance issues and how to troubleshoot them This book

CYMIC boilers using CFB technology – Valmet

circulation fluidised bed (CFB) boiler equipped for research purposes but also in a full- scale CFB boiler. The results were evaluated by means of IACM (on-line measurements

CYMIC boilers using CFB technology – Valmet

ACHIEVABLE COMBUSTION EFFICIENCY with ALSTOM CFB BOILERS

Circulating Fluidized Bed Boilers SpringerLink

fluidized bed boiler design and retrofits Challenges Today the goals typically are to meet new emission limits and to replace fossil fuels by bio fuels and waste. The increasing use of low quality fuels sets high demands on the understanding and control of the furnace processes in order to ensure satisfactory operation and furnace availability. Increasing use of renewable energy sources with

Evaluation of the performance of a commercial circulating

Simulation of a Circulating Fluidized Bed Combustor with

The circulating fluidized bed (CFB) is a developing technology for coal combustion to achieve lower emission of pollutants. By using this technology, up to 95% of pollutants can be absorbed before being emitted to the atmosphere. Introduction. Circulating fluidized bed is a relatively new technology with the ability to achieve lower emission of pollutants. Extensive research has been conducted

COMPOSITION OF OIL SHALE ASHES FROM PULVERIZED FIRING AND

Circulating Fluidized Bed Boilers 1st Edition – Elsevier

fluidized bed boiler, fluidized air supply system, start-up burners, lower and upper overfire air supply system, fuel fill chute, sand fill chute, bubble caps (spargers), economizer and steam drum. At the beginning, fluidized air should be send into boiler through bubble caps, and the sands, limestone

A coal combustion model for circulating fluidized bed

Open Access Comprehensive Simulator (CSFMB) Applied to

Pulverized combustion vs Circulating Fluidized Bed

Abstract−The performance of a commercial circulating fluidized bed boiler in the Yeosu thermal power plant, which has been operating since October 2011 by KOSEP, has been evaluated by using the IEA-CFBC model.

US7194983B2 Circulating fluidized bed boiler – Google

Open Access Comprehensive Simulator (CSFMB) Applied to

Oxy-fuel combustion in circulating fluidized bed boilers

There are two main types of fluidised bed combustion boilers: Bubbling fluidized bed (BFB) and circulating fluidised bed (CFB) boilers. In the bubbling type, because the velocity of the air is low, the medium particles are not carried

US7194983B2 Circulating fluidized bed boiler – Google

Circulating Fluidized Bed Boilers 1st Edition – Elsevier

Studies on circulating fluidized bed (CFB) boilers have being conducted at the Tsinghua University (TH) for about two decades and much of works are done to link the fundamentals with practical

COMMERCIAL APPLICATION OF WASTE-FUEL FIRED HYBRID

THERMAL ENGINEERING Vol. 54 No. 6 2007 CIRCULATING FLUIDIZED BED BOILERS ABROAD 503 heat exchangers. Anthracite will be used as fuel. The minimum load of the boiler …

STUDY OF CIRCULATING COAL FLUIDIZED BOILERS

CHARACTERISTICS OF THE INTERNALLY CIRCULATING FLUIDIZED BED BOILER T. HIROTA, T. OHSHITA, S. KOSUGI, S. NAGATO, T. HIGO, AND N. INUMARU Plant Engineering Division

Simulation of a Circulating Fluidized Bed Combustor with

Circulating Fluidized Bed Boilers Abroad Springer

Circulating Fluidized Bed Boiler Industrial BoilerOil

The Coordinated Control of Circulating Fluidized Bed Boiler with Intelligence Feedforward Control Xiao-Feng Li, Shi-He Chen, Qing Zhong *Guangdong Power Test and Research Institute.

Circulating Fluidized Bed Boilers 1st Edition – Elsevier

CYMIC boilers using CFB technology – Valmet

Characterization of 30 MWth Circulating Fluidized Bed

Heat Transfer in Circulating Fluidized Bed Pavel Rusheljuk Tallinn University of Technology Abstract Heat transfer in the circulating fluidized bed is, apart from the particle and gas mixing, the most important process contributing to the intensity of the physical and chemical processes. In fact, several different processes can be distinguished: particle-gas heat transfer, heat transfer

COMMERCIAL APPLICATION OF WASTE-FUEL FIRED HYBRID

Performance Analysis of 250 MW Lignite Fired Circulating

DESIGN OF CIRCULATING FLUIDIZED BED BOILERS

IEA Clean Coal Centre– Operating experience of low grade fuels in circulating fluidised bed combustion (CFBC) boilers 3 Preface This report has been produced by IEA Clean Coal Centre and is based on a survey and analysis of published

STUDY OF CIRCULATING COAL FLUIDIZED BOILERS

PDF. About this book. Introduction · Explains operation and scientific fundamentals of circulating fluidized bed (CFB) boilers · Outlines practical issues in industrial use · Teaches how to optimize design for maximum reliability and efficiency · Discusses operating and maintenance issues and how to troubleshoot them . This book provides practicing engineers and students with insight into

ACHIEVABLE COMBUSTION EFFICIENCY with ALSTOM CFB BOILERS

Towards Better Understanding of Circulating Fluidized Bed

3 The quality is the test of the character . It is our mission to satisfy our customers. Parameters Circulating Fluidized Bed Power Plant Boiler

A coal combustion model for circulating fluidized bed

Composition of Oil Shale Ashes from Pulverized Firing and Circulating Fluidized-Bed Boiler… 341 November the 5th, 2008. According to the information from the Narva TPPs,

Numerical Analysis of Coal Combustion in Circulating

Computational Fluid Dynamics (CFD) for fluidized bed

Circulating Fluidized Bed Boilers 3 Circulating Fluidized Bed Boilers Product Evolution 1978: The first fluidized bed boiler became operational

US7194983B2 Circulating fluidized bed boiler – Google

CYMIC boilers using CFB technology – Valmet

· Explains operation and scientific fundamentals of circulating fluidized bed (CFB) boilers· Outlines practical issues in industrial use· Teaches how to optimize design for maximum reliability and efficiency · Discusses operating and maintenance issues and how to troubleshoot them This book

Design and Analysis of Air Distributors and Bed Materials

280 ton CFB boiler for Metallurgical Plant When the ZG power plant began commercial operations in late June 2009, it marked a new era in the evolution of circulating fluidized bed (CFB) technology. At the heart of the 460 megawatt electric (MWe) ZG power plant is the worldâs largest CFB boiler, which is also the worldâs first once-through unit (OTU) supercritical CFB boiler. Large enough to

The Coordinated Control of Circulating Fluidized Bed

COMPOSITION OF OIL SHALE ASHES FROM PULVERIZED FIRING AND

ABSTRACT: A Circulating Fluidized Bed Combustor (CFBC) is a highly efficient combustor. It can handle It can handle various types of solid fuels such as coal, biomass or agricultural wastes.

Brief Introduction of Fluidized Bed Boiler

circulation fluidised bed (CFB) boiler equipped for research purposes but also in a full- scale CFB boiler. The results were evaluated by means of IACM (on-line measurements

Circulating Fluidized Bed Boilers 1st Edition – Elsevier

Circulating Fluidized Bed Boiler Industrial BoilerOil

Circulating Fluidized Bed Boilers SpringerLink

Basu has been associated with the development of fluidized bed boilers in industry, government laboratories and universities since 1972. His research at TUNS and Dalhousie University on circulating fluidized bed has allowed him to consult for boiler and energy companies in …

Towards Better Understanding of Circulating Fluidized Bed

Fluidized Bed Combustion FBC Boiler boilersinfo.com

A coal combustion model for circulating fluidized bed

Comprehensive Simulator (CSFMB) Applied to Circulating Fluidized Bed Boilers and Gasifiers Marcio L. de Souza-Santos* University of Campinas (UNICAMP), Faculty of Mechanical Engineering, Department of Energy, CP 6122, Campinas, SP 13083-970, Brazil Abstract: A comprehensive simulation program of bubbling fluidized beds (CSFB or CSFMB) has been able to repro-duce operations of circulating

STUDY OF CIRCULATING COAL FLUIDIZED BOILERS GIAP

Circulating Fluidized Bed Boilers Furnace Boiler

top o the fluid bed reactor results in a “circulating fluid bed” reactor, because the largest particles carried out by gas flow of the reactor are separated from the flue gas and returned back to the reactor.

Operating experience of low grade fuels in circulating

Circulating Fluidized Bed Boilers SpringerLink

Performance Analysis of 250 MW Lignite Fired Circulating

2 The quality is the test of the character . It is our mission to satisfy our customers. DHX series circulating fluidized bed boiler absorbs the advantages of circulating fluidized bed boiler both at home and abroad,

Towards Better Understanding of Circulating Fluidized Bed

COMMERCIAL APPLICATION OF WASTE-FUEL FIRED HYBRID

Comments are closed.