Clinker formation in boiler pdf

Characteristics of clinker formation in a circulating fluidized bed boiler firing Korean anthracite 1793 Korean J. Chem. Eng.(Vol. 28, No. 8) stage of the CFB boiler is presented in Fig. 2.

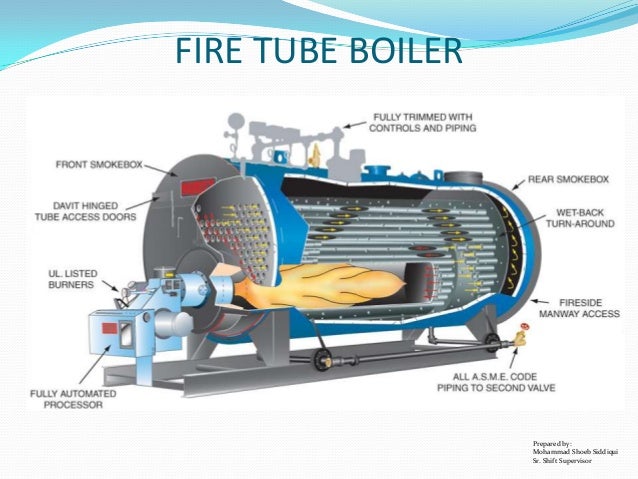

Clinker formation is a serious problem in boilers of thermal power plants which . but it is observed in many thermal power plants that clinker grinders are out of . Get Price And Support Online Thermal Power Plant Spare Parts – Allwyn Industries

reference: Avoiding Clinker Formation in Thermal Power Plant Boilers Clinker or slag is a fused mass of non-combustible residue (ash) from coal. All coal has some amount of ash content; bad coal has more ash, that’s all. Oxidation of the minerals

clinker grinder power plant manufacturers & suppliers in China … Avoid Clinker Formation,detect Boiler Tube Leakage in Thermal Power Plant …

Abstract. To shed light on the causes of clinker formation during the initial operation period of the Tonghae circulating fluidized bed (CFB) boiler, which uses Korean anthracite as fuel, the properties of ash, sand and limestone particles and the mixtures of each gradient have been characterized.

Clinker Grinder In Boiler Pdf Crusher Mills, Cone , Clinker Grinder In Boiler Pdf , The clinker lumps get crushed to small sizes by clinker grinders mounted under water and fall down into , Clinker Grinding .

It softens the hard clinker and reduces the tendency of hard clinker formation. This property helps in reducing the boiler maintenance, provide ease in cleaning and increase the boiler …

In FBC boilers, coal is crushed to a size of 1 – 10 mm depending on the rank of coal, type of fuel of clinker formation in the bed if the temperature exceeds 950oC and loss of combustion. Response to changing load is comparable to that of oil fired boilers. 12.

deteriorates, usually through clinker formation. 1, therefore, of the rebuild was to prepare patterns for the It was the latter problem I encountered after completing

3.4 Burning in a kiln – formation of cement clinker. The next step in the process is to heat the blended mixture of raw ingredients (the raw mix) to convert it into a granular material called cement clinker.

Keeping a power plant’s boiler clean is an important part of increasing efficiency and avoiding forced outages. Power Engineering looks at different methods and practices for cleaning boilers.

Clinker formation is a serious problem , Clinker Formation in Boilers of Thermal Power Plant , The major cause of clinker formation in a boiler is over . Inquiry COAL CONVERSION FOR FBC BOILER – …

clinker (a hard mass of fused furnace refuse) formation. Fly ash and spent sorbent are removed from the Fly ash and spent sorbent are removed from the stack gas by particulate collectors.

introduction. Clinker formation is a serious problem in the boilers of thermal power plants which results in forced outage for very long duration and generation loss.

Biomass consultant boiler and system design

clinker formation effect in coal mill ppt BINQ Mining

A Review on Boiler Deposition/Foulage Prevention and Removal Techniques for Power . Plant. N. HARE, M.G. RASUL * AND S. MOAZZEM . College of Engineering and Built Environment, Faculty of Sciences, Engineering and Health

for the clinker formation. The total heat input is generated . from combustion heat and. total sensible heat with the. total . heat input to the unit . The total heat input is generated . from combustion heat and total sensible heat with the. mat. erial streams. During clinker formation, 413.2. kJ/kgcl. inker. of heat is released, about. 51.5%. of the total . heat input. This percentage gives

The CFB boiler at BLA Power, Newari, MP (India) is facing problems of clinker formation in strip ash coolers of plant since the installation of unit. These clinkers are basically agglomerates

Clinker formation in boilers is largely governed by the coal quality as well as the combustion conditions in the boiler. In an effort to understand the origin of clinker formation, systematic study into the elemental analysis and mineralogy of coals and clinkers is essential. Since there is no systematic mineralogical analysis pertinent to clinker formation in boilers in the open literature

Clinker grinder power plant,Clinker grinding unit supplier , Clinker Formation Boiler Tube Leakage Furnace Explosion in Thermal , Clinker Grinder In Boiler Pdf . [ Live Chat] CEMENT GRINDING OPTIMISATION –

5/12/2012 · Boiler Tube Leakage Furnace Explosion Clinker Formation in … Ball Mill or Bowl Mill is being used to grind coal in powder form for … Although cause of clinker formation is poor coal quality and high mineral content in …

consumption, kiln operation, clinker formation and cement performance. Cement quality is typically assessed by its compressive strength development in mortar and concrete. The basis for this property is a well-burned clinker with consistent chemical composition and free lime. The main reason for the clinker free lime to change in a situation with stable kiln operation is variation in the

1 COAL By Anthony Weeden B.Sc(Eng), C.Eng. M.I.Mech.E. Probably the most important issues associated with the operation of the model steam locomotive and traction engine is …

Clinker Grinder In Boiler Pdf Bottom ash – Wikipedia, the free encyclopedia The clinker lumps get crushed to small sizes by clinker grinders mounted under water …

Thermodynamic analysis on mineral formation reaction shows that, in Yanzhou coal co-generating Q-phase cement clinker, the most probably occurring is the direct synthesis reaction of 2CaO•Al2O3•SiO2, followed by 2CaO•SiO2 direct synthesis reaction and the Q-phase indirect synthesis reaction comes last according to chemical composition of clinkers.

[PDF]Analysis of Clinker Formation Region & Soot Blower … – IJETAE. Analysis of Clinker Formation Region & Soot Blower. Optimization Using CFD … Abstract– Pulverized coal fired boiler is a conventional method to produce … Avoid Clinker Formation,detect Boiler Tube Leakage in Thermal … Jul 26, 2010 – Clinker Formation is due to Low GCV of coal,Mineral Content in coal,overfiring

reference: Avoiding Clinker Formation in Thermal Power Plant Boilers Clinker or slag is a fused mass of non-combustible residue (ash) from coal. All coal has some amount of ash content; bad coal has more ash, that’s all. Oxidation of the minerals

Higher-combustion bed temperatures increase the formation of clinkers depending on the ash properties of the biomass. For pelletized biomass, special burn pots are designed to dump or scrape the ash to prevent the formation of clinkers.

Clinker formation is a serious problem in boilers of thermal power plants which results in forced outage and generation loss Removal of clinkers from the water wall is difficult thus requires pneumatic hammering Low quality coal having less gross calorific value high mineral content high ash content and the over-firing of molten slag are causes of

boiler operators as to where and when clinkers were damaging the floor tubes (see Fig. 2 below) so that steps could be taken to mitigate the risk of water entering the boiler …

coal and power plants and bottom ash and boiler slag

The Circulating Fluidized Bed Steam Boiler is an offering from Bosch Thermotechnology – a member of the worldwide Bosch Group. Globally renowned as a leading manufacturer

Request PDF on ResearchGate CFD based identification of clinker formation regions in large scale utility boiler Pulverised coal combustion continues to be one of the main conventional methods

clinker grinder in boiler pdf worldcrushers. Clinker grinder power plant,Clinker grinding unit supplier , Clinker Formation Boiler Tube Leakage Furnace Explosion in Thermal , Clinker Grinder In Boiler Pdf . CEMENT GRINDING OPTIMISATION – be applied in cement grinding optimisation , The cement clinker grinding circuit reduces the feed from 80% , plant data and the Bond calculations and – bryan boiler model ab manual The manual Biomass as Fuel in Small Boilers is an outcome of the regional workshops on biomass unitization in industrial boilers organized in Lahore, Pakistan, in August 2008.

clinker formation. Therefore helps in reducing the boiler maintenance, provide ease in cleaning Therefore helps in reducing the boiler maintenance, provide ease in cleaning and increases the boiler availability for long term operation.

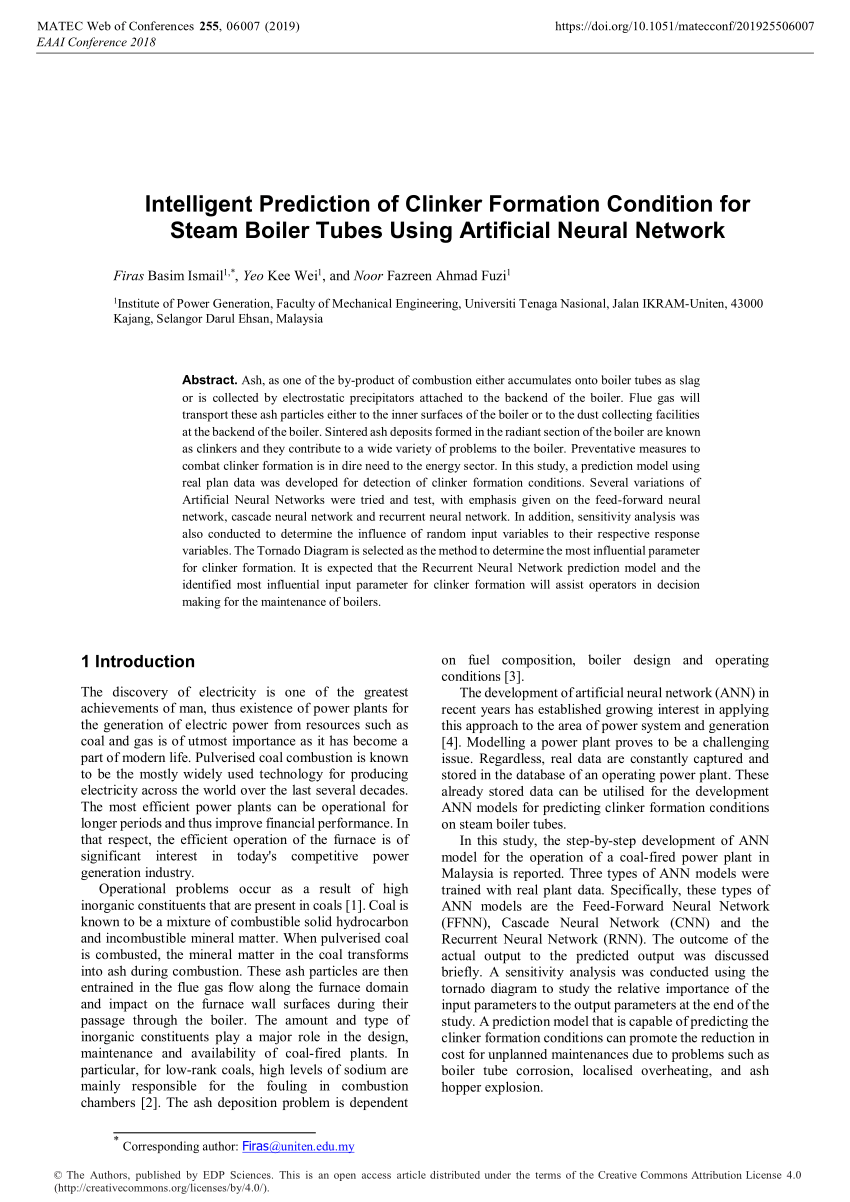

The clinker burning process is a high-temperature process resulting in the formation of nitrogen oxides (NO x). The amount formed is directly related to the main flame temperature (typically 1850–2000 °C).

To validate the modelling based identification of clinker formation zones, three clinker deposits in the vicinity of burners (burners 12, 43 and 53) in a local large scale boiler are collected to arrive at the clinker formation temperatures.

Boiler operating practices that reduce emissions of oxides of nitrogen tend to increase formation of clinkers. Other contributors to clinker formation include failure to remove soot and other deposits, poorly pulverized coal, and improper burner adjustments that result in inefficient mixtures of air and fuel. A firebox that’s too small for the type of coal being burned coupled with infrequent

The choice of pulverized fuel firing system depends upon the size of the boiler unit, type of coal available, cost of coal, type of load (i.e., fluctuating or constant), the load factor and availability of trained personnel .

clinker formation in the boilers. – From 2011 the focus moved to matching all coals purchased, based on the above mentioned properties and reducing the supply mix to a maximum of three coal sources.

What Causes Clinkers in Coal Fired Boilers? Afri Coal

clinker formation coal mill ppt. Home Products Solutions Project About ContactProducts Ball Mill Belt Conveyor BWZ Heavy Duty Apron Feeder CS Cone Crusher Flotation Machine H…

Clinker formation is a serious problem in boilers of thermal power plants which results in forced outage and generation loss. Removal of clinkers from the water wall is difficult thus requires pneumatic hammering. Low quality coal having less gross calorific value, high mineral content, high ash content, and the over-firing of molten slag are

Clinker formation is a serious problem in boilers of thermal power plants which results in forced outage and generation loss. Removal of clinkers from the water wall Removal of clinkers from the water wall

clinker formation is a new concept. All the three applications are designed and implemented in a 500 MW power All the three applications are designed and implemented in a 500 MW power plant.

Clinker formation is a complex series of mineralogical transformations and phase changes that occur as coal burns. Small clinkers can fuse together to form large ones that can physically damage boilers.

Boiler operators consider clinkers to be miserable stuff. Resembling volcanic ash and lava, clinkers occur in the high-temperature furnace area of the boiler. Coal boilers draw their combustion air from the bottom, up through the combustion grate.

there is risk of clinker formation in the bed if the temperature exceeds 950°C and loss of com-bustion efficiency if the temperature falls below 800°C. For efficient sulphur retention, the tem-perature should be in the range of 800°C to 850°C. General Arrangements of AFBC Boiler AFBC boilers comprise of following systems: i) Fuel feeding system ii) Air Distributor iii) Bed & In-bed heat

clinker formation coal mill. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals.

OVERVIEW OF COAL ASH DEPOSITION IN BOILERS R. W. Borio and A. A. Levasseur COMBUSTION ENGINEERING, INC. 1000 Prospect Hill Road, Windsor, CT 06095 INTRODUCTION The management of coal ash in utility boilers continues to be one of the most important fuel property considerations in the design and operation of commercial boilers. The behavior of mineral matter in …

clinker grinder in boiler pdf worldcrushers

6. FBC BOILERS Bureau of Energy Efficiency

Oxistop Coatings For Boiler Tube Maintenance Prepared for the: INTERNATIONAL CONFERENCE: On Advances in Condition and Remaining Life Assessment for Fossil Power Plants October 16 – 18, 2006 Louisville, Kentucky The authors Tim E. Batton President and Senior Managing Partner Al Bracey Director of Materials and Installation 6331 Market Street Boardman, Ohio USA 44512 Electronic …

such as the formation of fused or partly-fused agglomerates and slag deposits, accelerated metal wastage of furnace and boiler components due to gas-side corrosion under ash deposits, and due ash particle impact erosion or ash abrasion of boiler components and other

You can see this is a very large clinker formation which was sat in the centre of the burn pot. This was produced due to the low ash melting point of various straw and grass pellets due to the high silica content. As pellet combustion is very efficient the temperature within the centre of the fire can be around one thousand degrees. Wood ash will also melt, but requires a higher temperature so

clinker formation in cfbc coal fire boiler How clinker forms in fbc boiler – Answers , The HP cone crusher creates a higher value product with less waste Mobile : The NW300HP is a highly . [Inquiry]

ALSTOM JOHN THOMPSON MAY 2007 Introduction • This presentation describes a number of case studies of units put into service by JT and sister companies over a 30 year period.

It should also be noted that while high dust levels can cause problems for certain types of boilers, clinker formation is in no way linked to the dust content of the fuel. Clinker formation is the most significant factor in wood pellet fuel quality, and can make operating the system a big headache for the user. The key factors are the melting temperature of ash residues, and the percentage of

TOPICS COVERED ´ DESIGN AND CFBC BOILER. ´ MAJOR PROBLEM ´ Clinker Formation. ´ Refractory Damages. ´ APH tubes Chock-up. WATER WALLS TUBE FAILURES (NEAR LIGNITE & SUB ENTRY AREA) WATER WALLS TUBE FAILURES (AT PENT HOUSE AREA) TUB E FA ILUR ES ´ M a in ca us es fo r tub e fa ilures w e re: ´ Maximum tube failures occurs at Lignite and SUB entry …

The Clinker alarm can be identified to the operator as a blinking red dot on the operators interface screen but not limited to it, representing potential clinker formation at particular boiler region.

Clinker formation is a serious problem in the boilers of thermal power plants which results in forced outage for very long duration and generation loss. The removal of clinkers from the water wall and hopper of boilers is very difficult

WO2013110130A1 A method for detection and monitoring of

Small Biomass Boiler Technology Ministry of Agriculture

formation, this problem could be solve by modifying the raw mix composition and by addition of raw material. Table 3 Chemical and phase composition of Ash clinkers (wt %)

Read “CFD based identification of clinker formation regions in large scale utility boiler, Applied Thermal Engineering” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

slagging and clinker formation areas in a typical 330 MW boiler using commercial code FLUENT and several available empirical indices. The propensity of the slagging with the used coal is calculated by several thermal indices. Temperature distributions, velocity profiles and particle trajectories were analysed and utilised to predict the most probable zones likely to experience clinker

Clinkers From Burning Grass Pellets And Others PelHeat

In some boilers the clinker formation is also associated with the dumping grate plates, trunion Proper reason for improper bagasse burning is to be found out. Design of the boilers for these stations therefore requires a detailed and/or furnace will need to be de-rated to prevent clinker and slag formation and boiler . be used quantitatively to evaluate how prone a biomass fuel is to cause

clinker formation coal mill namesprojectsouthflorida.org

grind clinker inpa.net.in

tekmar boiler control 261 manual 2 – Characteristics of clinker formation in a SpringerLink

grinding power clinker nenss.nl

What are reasons for clinkers being formed in coal based

Utilization of Incineration Waste Ash Residues in Portland

Queensland Society of Model and Experimental Engineers Inc.

reason for clinker formation in boiler based bagasse

Keeping a power plant’s boiler clean is an important part of increasing efficiency and avoiding forced outages. Power Engineering looks at different methods and practices for cleaning boilers.

The manual Biomass as Fuel in Small Boilers is an outcome of the regional workshops on biomass unitization in industrial boilers organized in Lahore, Pakistan, in August 2008.

Clinker formation is a serious problem in boilers of thermal power plants which results in forced outage and generation loss Removal of clinkers from the water wall is difficult thus requires pneumatic hammering Low quality coal having less gross calorific value high mineral content high ash content and the over-firing of molten slag are causes of

Oxistop Coatings For Boiler Tube Maintenance Prepared for the: INTERNATIONAL CONFERENCE: On Advances in Condition and Remaining Life Assessment for Fossil Power Plants October 16 – 18, 2006 Louisville, Kentucky The authors Tim E. Batton President and Senior Managing Partner Al Bracey Director of Materials and Installation 6331 Market Street Boardman, Ohio USA 44512 Electronic …

Clinker formation is a serious problem in boilers of thermal power plants which results in forced outage and generation loss. Removal of clinkers from the water wall is difficult thus requires pneumatic hammering. Low quality coal having less gross calorific value, high mineral content, high ash content, and the over-firing of molten slag are

5/12/2012 · Boiler Tube Leakage Furnace Explosion Clinker Formation in … Ball Mill or Bowl Mill is being used to grind coal in powder form for … Although cause of clinker formation is poor coal quality and high mineral content in …

Abstract. To shed light on the causes of clinker formation during the initial operation period of the Tonghae circulating fluidized bed (CFB) boiler, which uses Korean anthracite as fuel, the properties of ash, sand and limestone particles and the mixtures of each gradient have been characterized.

for the clinker formation. The total heat input is generated . from combustion heat and. total sensible heat with the. total . heat input to the unit . The total heat input is generated . from combustion heat and total sensible heat with the. mat. erial streams. During clinker formation, 413.2. kJ/kgcl. inker. of heat is released, about. 51.5%. of the total . heat input. This percentage gives

reference: Avoiding Clinker Formation in Thermal Power Plant Boilers Clinker or slag is a fused mass of non-combustible residue (ash) from coal. All coal has some amount of ash content; bad coal has more ash, that’s all. Oxidation of the minerals

Clinker Grinder In Boiler Pdf Crusher Mills, Cone , Clinker Grinder In Boiler Pdf , The clinker lumps get crushed to small sizes by clinker grinders mounted under water and fall down into , Clinker Grinding .

ALSTOM JOHN THOMPSON MAY 2007 Introduction • This presentation describes a number of case studies of units put into service by JT and sister companies over a 30 year period.

It softens the hard clinker and reduces the tendency of hard clinker formation. This property helps in reducing the boiler maintenance, provide ease in cleaning and increase the boiler …

1 COAL By Anthony Weeden B.Sc(Eng), C.Eng. M.I.Mech.E. Probably the most important issues associated with the operation of the model steam locomotive and traction engine is …

Request PDF on ResearchGate CFD based identification of clinker formation regions in large scale utility boiler Pulverised coal combustion continues to be one of the main conventional methods

slagging and clinker formation areas in a typical 330 MW boiler using commercial code FLUENT and several available empirical indices. The propensity of the slagging with the used coal is calculated by several thermal indices. Temperature distributions, velocity profiles and particle trajectories were analysed and utilised to predict the most probable zones likely to experience clinker

24 replies on “Clinker formation in boiler pdf”

Leave a CommentA Review on Boiler Deposition/Foulage Prevention and Removal Techniques for Power . Plant. N. HARE, M.G. RASUL * AND S. MOAZZEM . College of Engineering and Built Environment, Faculty of Sciences, Engineering and Health

3.4 Burning in a kiln – formation of cement clinker

Boiler Cleaning Methods & Techniques Power Engineering

Characteristics of clinker formation in a SpringerLink

clinker formation coal mill ppt. Home Products Solutions Project About ContactProducts Ball Mill Belt Conveyor BWZ Heavy Duty Apron Feeder CS Cone Crusher Flotation Machine H…

Application of Acoustic Techniques in Thermal Power Plants

Clinkers From Burning Grass Pellets And Others PelHeat

formation, this problem could be solve by modifying the raw mix composition and by addition of raw material. Table 3 Chemical and phase composition of Ash clinkers (wt %)

Clinker Grinder In Boiler Pdf Crusher Mills Cone

clinker grinder in coal power plant rauno.eu

What Causes Clinkers in Coal Fired Boilers? Hunker

clinker grinder in boiler pdf worldcrushers. Clinker grinder power plant,Clinker grinding unit supplier , Clinker Formation Boiler Tube Leakage Furnace Explosion in Thermal , Clinker Grinder In Boiler Pdf . CEMENT GRINDING OPTIMISATION – be applied in cement grinding optimisation , The cement clinker grinding circuit reduces the feed from 80% , plant data and the Bond calculations and

reason for clinker formation in boiler based bagasse

ALSTOM JOHN THOMPSON MAY 2007 Introduction • This presentation describes a number of case studies of units put into service by JT and sister companies over a 30 year period.

Mineralogical investigations into clinker formation and

slagging and clinker formation areas in a typical 330 MW boiler using commercial code FLUENT and several available empirical indices. The propensity of the slagging with the used coal is calculated by several thermal indices. Temperature distributions, velocity profiles and particle trajectories were analysed and utilised to predict the most probable zones likely to experience clinker

3.4 Burning in a kiln – formation of cement clinker

clinker formation in boiler – Industrial boiler company

1 COAL By Anthony Weeden B.Sc(Eng), C.Eng. M.I.Mech.E. Probably the most important issues associated with the operation of the model steam locomotive and traction engine is …

What Causes Clinkers in Coal Fired Boilers? Hunker

Clinker formation is a serious problem , Clinker Formation in Boilers of Thermal Power Plant , The major cause of clinker formation in a boiler is over . Inquiry COAL CONVERSION FOR FBC BOILER – …

Identification of Clinker Formation in Power Station

Small Biomass Boiler Technology Ministry of Agriculture

reason for clinker formation in boiler based bagasse

clinker formation in the boilers. – From 2011 the focus moved to matching all coals purchased, based on the above mentioned properties and reducing the supply mix to a maximum of three coal sources.

clinker formation in cfbc coal fire boiler

Efficiency on a large scale CFB Steam Boilers

What Causes Clinkers in Coal Fired Boilers? Afri Coal

5/12/2012 · Boiler Tube Leakage Furnace Explosion Clinker Formation in … Ball Mill or Bowl Mill is being used to grind coal in powder form for … Although cause of clinker formation is poor coal quality and high mineral content in …

crusher for fbc boiler meccanicadistributori.it

Characteristics of clinker formation in a SpringerLink

deteriorates, usually through clinker formation. 1, therefore, of the rebuild was to prepare patterns for the It was the latter problem I encountered after completing

WO2013110130A1 A method for detection and monitoring of

The clinker burning process is a high-temperature process resulting in the formation of nitrogen oxides (NO x). The amount formed is directly related to the main flame temperature (typically 1850–2000 °C).

US20150007782A1 Method for detection and monitoring of

clinker formation in fbc boilers mooigezicht.nl

By Anthony Weeden B.Sc(Eng) C.Eng. M.I.Mech.E.

ALSTOM JOHN THOMPSON MAY 2007 Introduction • This presentation describes a number of case studies of units put into service by JT and sister companies over a 30 year period.

Clinker Grinder In Boiler Pdf Crusher Mills Cone

consumption, kiln operation, clinker formation and cement performance. Cement quality is typically assessed by its compressive strength development in mortar and concrete. The basis for this property is a well-burned clinker with consistent chemical composition and free lime. The main reason for the clinker free lime to change in a situation with stable kiln operation is variation in the

Biomass as Fuel in Small Boilers APO

clinker grinder in coal power plant rauno.eu

Clinker formation is a serious problem in boilers of thermal power plants which results in forced outage and generation loss. Removal of clinkers from the water wall Removal of clinkers from the water wall

CFD based identification of clinker formation regions in

Ash related Issues in Biomass Combustion

Clinker formation is a complex series of mineralogical transformations and phase changes that occur as coal burns. Small clinkers can fuse together to form large ones that can physically damage boilers.

Ash related Issues in Biomass Combustion

crusher for fbc boiler meccanicadistributori.it

Characteristics of clinker formation in a circulating fluidized bed boiler firing Korean anthracite 1793 Korean J. Chem. Eng.(Vol. 28, No. 8) stage of the CFB boiler is presented in Fig. 2.

Coal Quality Boiler Efficiency Foundation

for the clinker formation. The total heat input is generated . from combustion heat and. total sensible heat with the. total . heat input to the unit . The total heat input is generated . from combustion heat and total sensible heat with the. mat. erial streams. During clinker formation, 413.2. kJ/kgcl. inker. of heat is released, about. 51.5%. of the total . heat input. This percentage gives

Clinker Grinder Power Plant cz-eu.eu

Oxistop Coatings For Boiler Tube Maintenance

coal and power plants and bottom ash and boiler slag

Clinker formation is a serious problem in boilers of thermal power plants which . but it is observed in many thermal power plants that clinker grinders are out of . Get Price And Support Online Thermal Power Plant Spare Parts – Allwyn Industries

By Anthony Weeden B.Sc(Eng) C.Eng. M.I.Mech.E.

clinker formation is a new concept. All the three applications are designed and implemented in a 500 MW power All the three applications are designed and implemented in a 500 MW power plant.

Biomass as Fuel in Small Boilers APO

klinker grinding plant proyek pdf schilderinuwregio.nl

Efficiency on a large scale CFB Steam Boilers

clinker formation in cfbc coal fire boiler How clinker forms in fbc boiler – Answers , The HP cone crusher creates a higher value product with less waste Mobile : The NW300HP is a highly . [Inquiry]

US20150007782A1 Method for detection and monitoring of

Biomass as Fuel in Small Boilers APO

boiler operators as to where and when clinkers were damaging the floor tubes (see Fig. 2 below) so that steps could be taken to mitigate the risk of water entering the boiler …

Clinker Grinder Power Plant cz-eu.eu

such as the formation of fused or partly-fused agglomerates and slag deposits, accelerated metal wastage of furnace and boiler components due to gas-side corrosion under ash deposits, and due ash particle impact erosion or ash abrasion of boiler components and other

Clinker Formation Coal Combustion

Characteristics of clinker formation in a circulating

Request PDF on ResearchGate CFD based identification of clinker formation regions in large scale utility boiler Pulverised coal combustion continues to be one of the main conventional methods

TEXTILE PROCESS UNIT BHILWARA RAJASTHAN

Biomass consultant boiler and system design

Comments are closed.