Dealloying corrosion in boiler pdf

Failure of critical components like pipelines, tanks, pressure vessels, boilers and related equipment, heat exchangers often result in operating down time, loss of production, environmental pollution and in some cases, loss of human life.

Dealloying, selective leaching and graphitic corrosion can be prevented through the following methods: Select metals/alloys that are more resistant to dealloying . For example, inhibited brass is more resistant to dezincification than alpha brass, ductile iron is more resistant to graphitic corrosion …

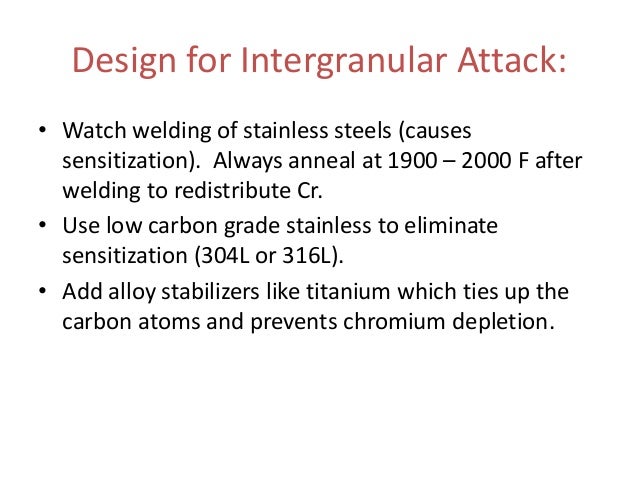

Erosion corrosion, Cavitation, Fretting corrosion, Intergranular corrosion, Exfoliation, and Dealloying (selective leaching or Selective Attack) are what specifies the depth of a certain corrosion …

Corrosion – Ebook download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world’s largest social reading and publishing site. Search Search

Understanding the dealloying mechanisms of gold-based alloy thin films resulting in the formation of nanoporous gold with a sponge-like structure is essential for the future design and integration of this novel class of material in practical devices. Here we report on the synthesis of nanoporous gold thin films using a free-corrosion approach

of cathodic protection to prevent localized corrosion and dealloying. DATA AND DISCUSSION Depth of Attack and Corrosion Rates The depth of attack and corrosion rate data for copper and the copper alloys have been shown in Table 2. All the un-protected materials had low corrosion rates; the maximum average rate observed was 0.74 mpy. The depth of attack data, however, showed that …

Dealloying and Corrosion of Al Alloy 2024-T3 M. B. V ukmirovic, a, * N. Dimitrov , b, ** and K. Sieradzki a,b,c, ** ,z a Program in The Science and Engineering of Materials, b Department of

The control of corrosion in a boiler environment is based on maintaining conditions, which enhance passive film formation. Magnetite is the preferred high temperature iron oxide form.

Different Types of Corrosion Dealloying is the selective corrosion of one or more components of a solid solution alloy. It is also called parting, selective leaching or selective attack. Common dealloying examples are decarburization, decobaltification, denickelification, dezincification, and graphitic corrosion…

IN SUPERHEATER/REHEATER CORROSION

Monolithic nanoporous copper by dealloying Mn–Cu Journal

corrosion rate was approximately 120 mpy at 1100″F, and about 260 mpy at 1200°F. Hieh-CI British coal – Similarly, the corrosion occurring on the probes at the 30 to 90″ locations was more severe than that at the leading edge.

Corrosion protection for boilers In today’s increasingly competitive commercial environment, engineering solutions are expected to improve product yields and plant operational reliability.

Preparation of three-dimensional nanoporous Si using dealloying by metallic melt and application as a lithium-ion rechargeable battery negative electrode. Journal of Power Sources , Vol. 306, p. 8.

2 Introduction Corrosion is a major problem in various technical fields from the oil, gas, and chemical industry 1 to biomedical implants 2, 3 or infrastructures4.

corrosion Corrosion Dealloying corrosion Cracki Corrosion with a mechanical component Erosion corrosion Fretting corrosion Cavitation and water drop impingement Corrosion fatigue Cracking produced by corrosion, in the presence of stress. Stress – ng (SCC) Hydrogen Damage Liquid metal embrittlement Solid metal induced embrittlement (Ref: Sully J R, Taylor D. W, Electrochemical …

Dr. Dmitri Kopeliovich Selective corrosion (dealloying, selective leaching) is a preferential attack of a particular component of an alloy in presence of electrolyte as a result of an electrochemical oxidation-reduction (redox) process.

Graphitic Corrosion) is sometimes considered to be a form of dealloying. which contain small concentrations of phosphorus. sheets of oxide corrosion products can peel (exfoliate) off surfaces (Fig. 15. Eventually. In the presence of high-pressure oxygenated steam. arsenic.

NALCO Chemical Company. Nalco Guide to Boiler Failure Analysis, 2nd Edition. US: McGraw-Hill Professional, 2011.

ASM-74892G NALCO Guide to Boiler Failure Analysis 2/e Practical, up-to-date techniques for identifying and eliminating common causes of boiler failure Filled with more than 200 color images, The Nalco Guide to Boiler Failure Analysis , Second Edition categorizes distinct failure modes that typify nearly all boiler problems and walks you, step by step, through their solutions.

SELECTIVE LEACHING (“Dealloying”, “Parting”) Corrosion in which one constituentofan alloy is preferentially removed, leaving behind an altered (weakened) residual structure. Can occurin several systems. Combinations ofalloys and environments subjectto dealloying and elements preferentially removed Alloy Environment Element removed Brasses Many waters, especially understagnant Zinc

corrosive attack, such as stress-corrosion crack ing, dealloying, or pitting. However, because uniform thinning plays an important role in all of the categories described, each can and will be discussed under general corrosion. Atmospheric Corrosion Atmospheric corrosion is defined as the corrosion or degradation of material exposed to the air and its pollutants rather than im mersed in a

The dealloying behaviour of Au42Cu29Ti8Si21 and Au44Cu31Ti4Si21 amorphous (wheel-side) and partially crystalline (air-side) ribbons was investigated using potentiostatic and galvanostatic etching.

To develop a boiler tube corrosion management system that can effectively aid the reduction in tube leaks through predictive inspection and maintenance. Our Solution The development of specialised Fireside Corrosion mapping software linked with tube inspection techniques, which enable boiler engineers to pinpoint present and future problem areas, and reduce tube leaks. Features – ability to

MANAGING CORROSION CHALLENGES ASSOCIATED WITH HEAT EXCHANGERS For Presentation at GPA-GCC Special Session on Corrosion Management in Gas Processing Facilities

Corrosion troubles in low pressure heating boilers — which usually operate at a steam pressure below 15 psig or water pressures below 30 psig and are often of the horizontal fire tube type — …

Corrosion for Engineers Dr. DerekH. Uster Chapter 10: EROSION CORROSION page 10 – 1 EROSION CORROSION (“Flow-Assisted” Corrosion) An increase in corrosion …

Corrosion Prevention and Control: A Program Management Guide for Selecting Materials September, 2006 v Preface This handbook was produced by the Advanced Materials, Manufacturing, and …

The Nalco Water Guide to Boiler Failure Analysis Second

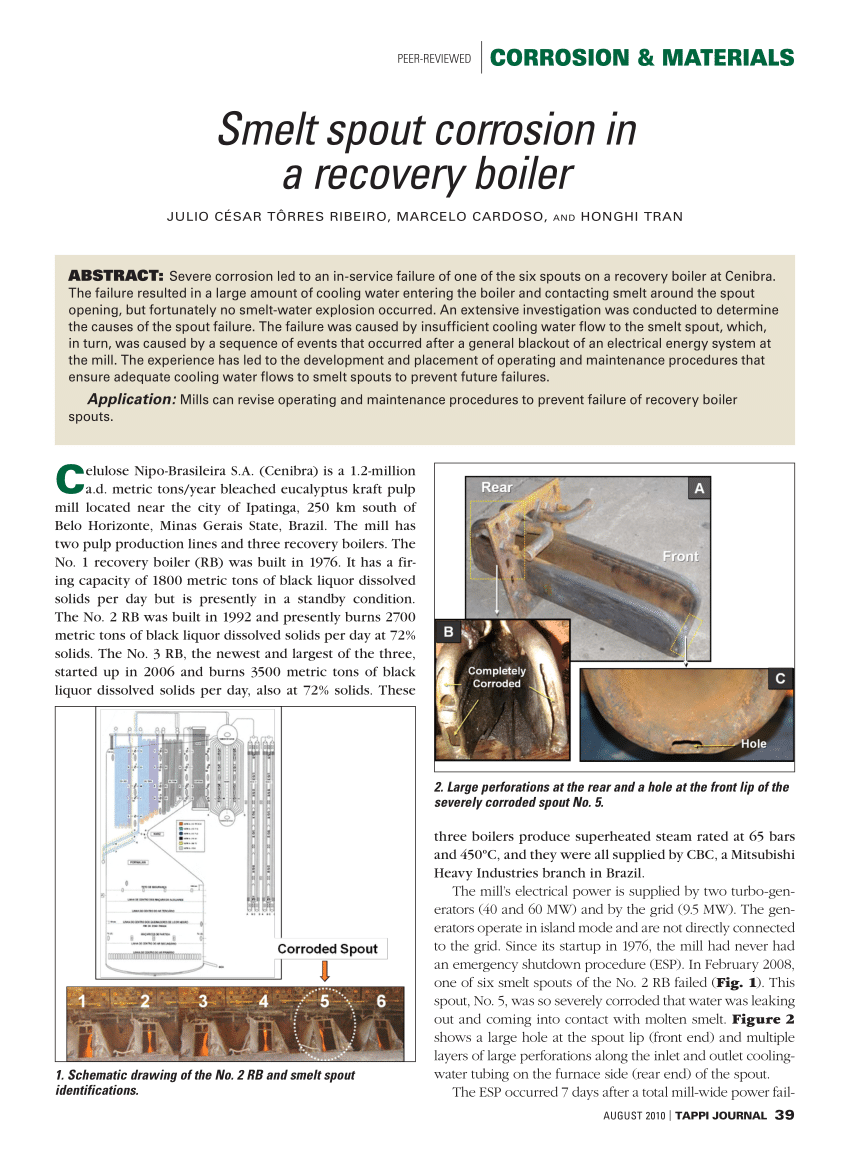

corrosion has ever been reported in Boiler C. Figure 4 shows a schematic of the lance tubes for the new soot blowers in Boilers A and B: the lance outside diameter is 102 mm (4”).

CORROSION TEACH-IN Simulating Real World Corrosion Problems. Dealloying of Copper Nickel Alloys •Scope • A copper-nickel pipe made of Cupronickel 30 has been preferentially dealloyed while in contact with a 26 weight percent calcium chloride brine. It appears that the nickel in the alloy has been preferentially removed. Dealloying of Copper Nickel Alloys •Purpose • The OLI

Corrosion in Metals M o hd . H a n if D e w an , I E ng , I M ar E ng , M I M arE S T ( U K ) , M R I NA (U K ), M a ritime L ectu re r a nd C on sulta nt. Corrosion WHAT IS CORROSION Corrosion is the deterioration of materials by chemical interaction with their environment. The term corrosion is sometimes also applied to the degradation of plastics, concrete and wood, but generally refers to

Dealloying – Dealloying (also referred to as selective leaching) is the selective removal of one element of a solid alloy by a corrosion process. A corrosive medium specifically attacks one component of the alloy. A common example of this type of corrosion is the selective removal of zinc from brass (dezincification). Nickel retains an austenitic, face-centered-cubic (fcc) crystal structure

This corrosion type is supposed to be dealloying (dealuminification): selective removal of aluminum from the surface, and a percolating cluster of silicon atoms provides a continuous active pathway for the corrosion process as well as a pathway

Although graphitic corrosion is often considered to be a form of dealloying or selective leaching, it actually has more in common with galvanic corrosion. Microscopic galvanic cells form between the metal matrix and graphite

corrosion performance in biomass boiler conditions, both in laboratory conditions and in real biomass boilers. According to this research, the tested HVOF sprayed nickel- and iron-based coatings can offer protection for low-alloy substrates in biomass boiler conditions. The results of the present study will help optimize the coating process for high temperature corrosion applications, and in

The corrosion behavior of these alloys is significantly different and much more complex than that of a single metal. Differences in the tendencies for corrosion of the various components of an

Dealloying corrosion, or selective leaching, is a type of elec- trochemical corrosion where at least one element from an alloy is preferentially leached out into the corrosive fluid. – oil boiler manuals free download The results showed that the dealloying corrosion rate decreased and contribution of the transient shift from low-frequency parts (diffusion process) to the high-fre- quency parts (dissolution process) increased with the content of Cu increasing.

Steam and high temperature hot water boilers 6 Technology overview Boilers A boiler is a device that converts the chemical energy of a fuel into a useful heat output, such as

Dealloying or selective leaching refers to the selective removal of one element from an alloy by corrosion processes. A common example is the dezincification of unstabilized brass, whereby a weakened, porous copper structure is produced.

Pre-boiler corrosion will include corrosion in all steam – condensate network and also in boiler feed water section. Therefore corrosion in all areas that at the end will impact in higher iron or copper concentrations arriving to boiler will be included in this definition. Pre-boiler corrosion defines the area where the phenomenon takes place, but it may includes different corrosion

Dealloying process, if present, will determine an alloy’s corrosion resistance, therefore various systems were examined with respect to their electrochemical responses, either for the alloy’s practical importance, such as Zn-Cu and Al-Cu, or for its simplicity like Ag-

Corrosion Glossary deactivation. The process of prior removal of the active corrosive constituents usually oxygen, from a corrosive liquid by controlled corrosion of expendable metal or by other chemical means, thereby making the liquid less corrosive. dealloying. The selective corrosion of one or more components of a solid solution alloy, usually in the form of ions. Also called parting or

Download nalco guide to boiler failure analysis second edition or read online here in PDF or EPUB. Please click button to get nalco guide to boiler failure analysis second edition book now. All books are in clear copy here, and all files are secure so don’t worry about it.

Monolithic nanoporous copper was synthesized by dealloying Mn 0.7 Cu 0.3 by two distinct methods: potentiostatically driven dealloying and free corrosion. Both the ligament size and morphology were found to be highly dependent on the dealloying methods and conditions. For example, ligaments from 16 nm–125 nm were obtained by dealloying either electrochemically or by free corrosion

Corrosion The term corrosion has its origin in Latin. The Latin term rodere means ‘gnawing’ and corrodere means ‘gnawing to pieces’. Corrosion is the destructive attack of a metal by chemical or electrochemical reaction with its environment. Deterioration by physical causes is not called corrosion, but is described as erosion, galling, or wear. In some instances, chemical attack

written for CORROSION 2011, but with new case studies. The full article can be obtained at . www.nace.org examines microstructures of common → Store → Conference Papers. INTRODUCTION . It is difficult to know what exact temperature a boiler tube has been exposed to over its lifetime. When this information is needed for a tube analysis, one possibility is to calculate an equivalent tube

Practical, up-to-date techniques for identifying and eliminating common causes of boiler failure. Filled with more than 200 color images, The Nalco Guide to Boiler Failure Analysis, Second Edition categorizes distinct failure modes that typify nearly all boiler problems and walks you, step by step, through their solutions.

Oxygen corrosion can be frequently observed during stand still of boilers (if the pressure is 0 and steam is replaced by air) which leads to local corrosion (pitting), see Fig. 3 + 4 and as atmospheric corrosion on carbon steel.

Materials Research Tailored Dealloying Products of Cu-based Metallic Glasses in Hydrochloric Acid Solutions Zhifeng Wang, Lijuan Wang, Chunling Qin*, Jiangyun Liu, Yongyan Li, Weimin Zhao

Boiler: A boiler is a closed vessel in which water is heated, steam is generated, superheated or any combination thereof under pressure or vacuum by the direct application of heat from combustible fuels or

Selective leaching, also called dealloying, demetalification, parting and selective corrosion, is a corrosion type in some solid solution alloys, when in suitable conditions a component of the alloys is preferentially leached from the material.

Reducing Corrosion and potential Boiler Failure with

Practical, up-to-date techniques for identifying and eliminating common causes of boiler failure . Filled with more than 200 color images, The Nalco Guide to Boiler Failure Analysis, Second Edition categorizes distinct failure modes that typify nearly all boiler problems and walks you, step by step, through their solutions.

Download Nalco Guide To Boiler Failure Analysis Second Edition ebook PDF or Read Online books in PDF, EPUB, and Mobi Format. Click Download or Read Online button to NALCO GUIDE TO BOILER FAILURE ANALYSIS SECOND EDITION book pdf for free now.

in the boiler, causing problems such as underdeposit corrosion, and to copper deposition in high pressure turbines, leading to power losses. This aspect of the problem with condensers

Unusual Dealloying Effect in Gold/Copper Alloy Thin Films

Corrosion Corrosion Anode

Corrosion Glossary BAC Corrosion Control Ltd

Corrosion mechanisms and models for flue gas corrosion in

Welcome to the CORROSION TEACH-IN Simulating Real World

API 571 Damage Mechanisms Affecting Fixed Equipment in the

(PDF) Dealloying and Corrosion of Al Alloy 2024-T3

– Corrosion for Engineers Chapter 10 EROSION CORROSION page

Affection of Cu content on the phase evolution during the

Dealloying of an Au-based amorphous alloy Request PDF

(PDF) Selective Corrosion of Alloys ResearchGate

Selective corrosion (dealloying) [SubsTech]

SELECTIVE LEACHING CANDU Owners Group

The dealloying behaviour of Au42Cu29Ti8Si21 and Au44Cu31Ti4Si21 amorphous (wheel-side) and partially crystalline (air-side) ribbons was investigated using potentiostatic and galvanostatic etching.

Graphitic Corrosion) is sometimes considered to be a form of dealloying. which contain small concentrations of phosphorus. sheets of oxide corrosion products can peel (exfoliate) off surfaces (Fig. 15. Eventually. In the presence of high-pressure oxygenated steam. arsenic.

of cathodic protection to prevent localized corrosion and dealloying. DATA AND DISCUSSION Depth of Attack and Corrosion Rates The depth of attack and corrosion rate data for copper and the copper alloys have been shown in Table 2. All the un-protected materials had low corrosion rates; the maximum average rate observed was 0.74 mpy. The depth of attack data, however, showed that …

corrosive attack, such as stress-corrosion crack ing, dealloying, or pitting. However, because uniform thinning plays an important role in all of the categories described, each can and will be discussed under general corrosion. Atmospheric Corrosion Atmospheric corrosion is defined as the corrosion or degradation of material exposed to the air and its pollutants rather than im mersed in a

25 replies on “Dealloying corrosion in boiler pdf”

Leave a CommentThe results showed that the dealloying corrosion rate decreased and contribution of the transient shift from low-frequency parts (diffusion process) to the high-fre- quency parts (dissolution process) increased with the content of Cu increasing.

(PDF) Selective Corrosion of Alloys ResearchGate

Monolithic nanoporous copper by dealloying Mn–Cu Journal

Dr. Dmitri Kopeliovich Selective corrosion (dealloying, selective leaching) is a preferential attack of a particular component of an alloy in presence of electrolyte as a result of an electrochemical oxidation-reduction (redox) process.

Tailored Dealloying Products of Cu-based Metallic Glasses

Boiler: A boiler is a closed vessel in which water is heated, steam is generated, superheated or any combination thereof under pressure or vacuum by the direct application of heat from combustible fuels or

Dealloying technique in the synthesis of lithium-ion

Practical, up-to-date techniques for identifying and eliminating common causes of boiler failure. Filled with more than 200 color images, The Nalco Guide to Boiler Failure Analysis, Second Edition categorizes distinct failure modes that typify nearly all boiler problems and walks you, step by step, through their solutions.

Monolithic nanoporous copper by dealloying Mn–Cu Journal

Dealloying – Dealloying (also referred to as selective leaching) is the selective removal of one element of a solid alloy by a corrosion process. A corrosive medium specifically attacks one component of the alloy. A common example of this type of corrosion is the selective removal of zinc from brass (dezincification). Nickel retains an austenitic, face-centered-cubic (fcc) crystal structure

Introduction to Corrosion and Process Rust Bullet

Selective leaching, also called dealloying, demetalification, parting and selective corrosion, is a corrosion type in some solid solution alloys, when in suitable conditions a component of the alloys is preferentially leached from the material.

Formation of nanoporous platinum by selective dissolution

Corrosion protection for boilers AZZ

Erosion corrosion, Cavitation, Fretting corrosion, Intergranular corrosion, Exfoliation, and Dealloying (selective leaching or Selective Attack) are what specifies the depth of a certain corrosion …

SELECTIVE LEACHING CANDU Owners Group

Aspects of Failure of Condenser tubes and their Remedial

Understanding the dealloying mechanisms of gold-based alloy thin films resulting in the formation of nanoporous gold with a sponge-like structure is essential for the future design and integration of this novel class of material in practical devices. Here we report on the synthesis of nanoporous gold thin films using a free-corrosion approach

IN SUPERHEATER/REHEATER CORROSION

of cathodic protection to prevent localized corrosion and dealloying. DATA AND DISCUSSION Depth of Attack and Corrosion Rates The depth of attack and corrosion rate data for copper and the copper alloys have been shown in Table 2. All the un-protected materials had low corrosion rates; the maximum average rate observed was 0.74 mpy. The depth of attack data, however, showed that …

Nalco Guide to Boiler Failure Analysis by Daniel Flynn

Formation of nanoporous platinum by selective dissolution

Corrosion Prevention and Control: A Program Management Guide for Selecting Materials September, 2006 v Preface This handbook was produced by the Advanced Materials, Manufacturing, and …

Tailored Dealloying Products of Cu-based Metallic Glasses

Scaling Corrosion and Water Treatment on Steam Generator

To develop a boiler tube corrosion management system that can effectively aid the reduction in tube leaks through predictive inspection and maintenance. Our Solution The development of specialised Fireside Corrosion mapping software linked with tube inspection techniques, which enable boiler engineers to pinpoint present and future problem areas, and reduce tube leaks. Features – ability to

MANAGING CORROSION CHALLENGES ASSOCIATED WITH HEAT EXCHANGERS

Welcome to the CORROSION TEACH-IN Simulating Real World

Although graphitic corrosion is often considered to be a form of dealloying or selective leaching, it actually has more in common with galvanic corrosion. Microscopic galvanic cells form between the metal matrix and graphite

Morphology Evolution in Dealloying by Qing Chen

Corrosion Glossary deactivation. The process of prior removal of the active corrosive constituents usually oxygen, from a corrosive liquid by controlled corrosion of expendable metal or by other chemical means, thereby making the liquid less corrosive. dealloying. The selective corrosion of one or more components of a solid solution alloy, usually in the form of ions. Also called parting or

Aspects of Failure of Condenser tubes and their Remedial

SELECTIVE LEACHING CANDU Owners Group

Erosion corrosion, Cavitation, Fretting corrosion, Intergranular corrosion, Exfoliation, and Dealloying (selective leaching or Selective Attack) are what specifies the depth of a certain corrosion …

MANAGING CORROSION CHALLENGES ASSOCIATED WITH HEAT EXCHANGERS

Morphology Evolution in Dealloying by Qing Chen

Aspects of Failure of Condenser tubes and their Remedial

To develop a boiler tube corrosion management system that can effectively aid the reduction in tube leaks through predictive inspection and maintenance. Our Solution The development of specialised Fireside Corrosion mapping software linked with tube inspection techniques, which enable boiler engineers to pinpoint present and future problem areas, and reduce tube leaks. Features – ability to

Corrosion Characteristics and Response to in Quiescent

SELECTIVE LEACHING CANDU Owners Group

Tailored Dealloying Products of Cu-based Metallic Glasses

Corrosion The term corrosion has its origin in Latin. The Latin term rodere means ‘gnawing’ and corrodere means ‘gnawing to pieces’. Corrosion is the destructive attack of a metal by chemical or electrochemical reaction with its environment. Deterioration by physical causes is not called corrosion, but is described as erosion, galling, or wear. In some instances, chemical attack

Tailored Dealloying Products of Cu-based Metallic Glasses

The control of corrosion in a boiler environment is based on maintaining conditions, which enhance passive film formation. Magnetite is the preferred high temperature iron oxide form.

MANAGING CORROSION CHALLENGES ASSOCIATED WITH HEAT EXCHANGERS

Affection of Cu content on the phase evolution during the

Formation of nanoporous platinum by selective dissolution

ASM-74892G NALCO Guide to Boiler Failure Analysis 2/e Practical, up-to-date techniques for identifying and eliminating common causes of boiler failure Filled with more than 200 color images, The Nalco Guide to Boiler Failure Analysis , Second Edition categorizes distinct failure modes that typify nearly all boiler problems and walks you, step by step, through their solutions.

Dealloying of an Au-based amorphous alloy Request PDF

Corrosion for Engineers Dr. DerekH. Uster Chapter 10: EROSION CORROSION page 10 – 1 EROSION CORROSION (“Flow-Assisted” Corrosion) An increase in corrosion …

Selective leaching Wikipedia

Formation of nanoporous platinum by selective dissolution

Graphitic Corrosion) is sometimes considered to be a form of dealloying. which contain small concentrations of phosphorus. sheets of oxide corrosion products can peel (exfoliate) off surfaces (Fig. 15. Eventually. In the presence of high-pressure oxygenated steam. arsenic.

API 571 Damage Mechanisms Affecting Fixed Equipment in the

corrosive attack, such as stress-corrosion crack ing, dealloying, or pitting. However, because uniform thinning plays an important role in all of the categories described, each can and will be discussed under general corrosion. Atmospheric Corrosion Atmospheric corrosion is defined as the corrosion or degradation of material exposed to the air and its pollutants rather than im mersed in a

Forms of Corrosion in the Petrochemical Industry (Part 1)

The dealloying behaviour of Au42Cu29Ti8Si21 and Au44Cu31Ti4Si21 amorphous (wheel-side) and partially crystalline (air-side) ribbons was investigated using potentiostatic and galvanostatic etching.

Different Forms of Corrosion Dealloying Selective

API 571 Damage Mechanisms Affecting Fixed Equipment in the

Reducing Corrosion and potential Boiler Failure with

Download Nalco Guide To Boiler Failure Analysis Second Edition ebook PDF or Read Online books in PDF, EPUB, and Mobi Format. Click Download or Read Online button to NALCO GUIDE TO BOILER FAILURE ANALYSIS SECOND EDITION book pdf for free now.

API 571 Damage Mechanisms Affecting Fixed Equipment in the

Corrosion eng.utq.edu.iq

Dealloying – Dealloying (also referred to as selective leaching) is the selective removal of one element of a solid alloy by a corrosion process. A corrosive medium specifically attacks one component of the alloy. A common example of this type of corrosion is the selective removal of zinc from brass (dezincification). Nickel retains an austenitic, face-centered-cubic (fcc) crystal structure

Aspects of Failure of Condenser tubes and their Remedial

Corrosion troubles in low pressure heating boilers — which usually operate at a steam pressure below 15 psig or water pressures below 30 psig and are often of the horizontal fire tube type — …

Nalco Guide to Boiler Failure Analysis by Daniel Flynn

Affection of Cu content on the phase evolution during the

Dealloying (selective leaching) The Worldwide Corrosion

Comments are closed.