Induction heating power calculation pdf

P = π ⋅ d ⋅ h ⋅ H µ⋅ π ⋅ ρ⋅ µ 0 ⋅ r 4 Properties of induction heating 4 . 1 Power Transfer : simplified cal culation The load of an induction installation is heated because of the Joule effect as a …

Abstract: A power electronic inverter is developed for a high-frequency induction heating application. The The application requires high power for induction melting process of the electric furnace.

Induction heating systems employ non-contact heating. Inducing heat electromagnetically rather than using a heating element in contact with a part to conduct heat, as does resistance heating. This paper presents a technique to calculate the parameters of the coil to be used to heat an iron piece of given parameters, to 850 oC. A design of the full bridge power resonant inverter is presented

Calculation of Power Required Heating equipment using Elmatic Heating Elements will utilise one or more of the following methods for transfer‐

4 Properties of induction heating 4.1 Power Transfer: simplified calculation The load of an induction installation is heated because of the Joule effect as a result of induced eddy

Magnetic Fields and Induced Power in the Induction Heating of Aluminium Billets Mark Willia M kennedy licentiate Thesis in Materials Science and engineering

The induction heating power supply’s internal timer can be used to control cycle time; temperature control feedback for each individual part can be provided with thermocouples, IR thermometers or visual temperature sensors.

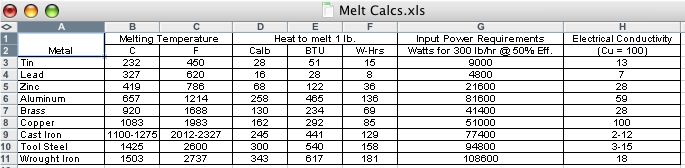

induction heating power supply, while still allowing easy insertion and removal of the part. Power Supply Capacity. The size of the induction power supply required for heating a particular part can be easily calculated. First, one must determine . how much energy needs to be transferred to the work-piece. This depends on the mass of the material being heated, the specific heat of the material

measured consist of the electric ity power put into the furnace, the temperature of liquid steel in the furnace, the temperature of input and output cooling water, flow rate of cooling water,

induction heating Abstract. Induction heating inverters are generally equipped with water-cooling systems. This results from considerable, of at least several kilowatt, power of these devices as well as from the easy availability of water-cooling used commonly, for example, for cooling the inductor. The paper presents a method for the calculation of water cooling of radiators based on the use

The induction heating power supply used for the experiments was the Inductoheat SP16. This power supply uses a voltage-fed inverter with power controlled by the operating frequency. The maximum output frequency of the series-tuned power supply is 20 …

Induction Heating Introduction of induction heating Induction heating is a process which is used to bond, harden or soften metals or other conductive materials.

Gy. Györök. A Special Case of Electronic Power Control of Induction Heating Equipment – 236 – Figure 1 The metal target inside the water-cooled coil.

induction heating using high-frequency resonant inverters. It is designed to replace ordinary stove plates. Although induction cooking has high initial cost in comparison with a conventional stove plate, it has many advantages including cleanness, safety, high efficiency, high The currents generate heat in the pan walls.power density, high reliability, maintainability and controllability [4

Induction Heating Calculation Tool Home / LEARN ABOUT INDUCTION HEATING / Induction Heating Calculation Tool Please input information about your induction heating application.

A common misassumption in induction hardening

Heat calculations for water-cooled radiators of the

Online induction heating power calculation Please fill out the parameters below for your theoretical induction heating process calculation. This power calculation gives you approximate refrence value for your induction heating application.

Temperature Estimation of Liquid Steel in Induction Furnace Anuwat Pansuwan, Krit Smerpitak and Prapart Ukakimaparn Abstract—This article presents the indirect measures of temperature by measuring the energy put into the furnace, temperature and flow rate of cooling water and temperature at the outer wall lining of the induction furnace in order to estimate the temperature of the liquid

Basics of induction The heating occurs without physical contact, it involves only the metal parts to be treated and it is characterized by a high efficiency transfer without loss of heat.

Induction heating is an accurate, fast, repeatable, efficient, non-contact technique for heating metals or any other electrically-conductive materials. An induction heating system consists of an induction power supply for converting line power to an alternating current and delivering it to a

The efficiency of an induction heating system for a specific application depends on several factors: the characteristics of the part itself, the design of the inductor, the capacity of the power supply, and the amount of temperature change required for the application.

Typical induction heating applications involve a drive coil with high currents at some kilohertz (kHz) frequency and a conductive target object placed inside or near the drive coil to induce currents and create heat (Figure 1). For high-power induction heaters, the drive coils are hollow with liquid cooling. Additional thermal/structural parts are used to support the heated object and to

is too low, center, a higher power density and large heat-affected zone result, which can waste energy and cause excessive distortion. The optimum frequency, right, results in a current penetration

Loss Minimization in Parallel & Series Induction Heating Inverters Using Genetic Algorithm H.Atighechi, H.Javadi, A.Shoulaie Department of electrical engineering

Power calculation for inductive heating of steel. Power calculation of temperature difference for shrink fits. Calculation of the power required for induction heating. Power calculation of temperature difference for shrink fits.

In the design of an induction heating installation, fundamental problems are the prediction of the heating time, the corresponding induced power and how the power can be controlled during heating in order to obtain in the workpiece the final temperature distribution required by …

9/05/2014 · Plustherm induction heating power calculator: Refer to this tutorial for help calculating power requirments and other necessary parameters for our induction heating generator.

Using this information induction power supply capacity can be select using following calculation. Let desired yearly production is 2000 ton in steel induction furnace Therefore daily production would be 2000/240 day = 8.33 ton/day (base of 240 working days in a year.

Loughborough University Institutional Repository Transistorised induction heating power supplies using MOSFET’s This item was submitted to Loughborough University’s Institutional Repository

23 ELECTROMAGNETIC INDUCTION, AC CIRCUITS, AND ELECTRICAL TECHNOLOGIES Figure 23.1This wind turbine in the Thames Estuary in the UK is an example of induction at work.

Induction Heating Power Supplies Besides the induction coil and workpiece, the induction generator (source of ac power) is probably the most important component of an over-all induction heating system. Such equipment is typically rated in terms of its frequency and maximum output power (in kilowatts). The discussion in this chapter addresses the selection of power supplies in terms of …

Estimation of the required power and dynamics of induction heating 3.3.1. Estimation of the required power for induction heating 3.3.2. Intricacies of the dynamics of induction heating . 4 3.4. Advanced induction principles and mathematical modeling 3.4.1. Mathematical modeling of the electromagnetic field 3.4.2. Mathematical modeling of the thermal processes 3.4.3. Numerical computation of

The rated power of natural gas-fueled appliances is specified by heat rate in terms of British thermal units per hour, or Btu/h, rather than kW.

Induction heating is a non-contact heating process. It uses high frequency electricity to heat materials that are electrically conductive. Since it is non-contact, the heating process does not contaminate the material being heated.

Plustherm Point Ltd. is an innovative SME company headquartered in Switzerland. Our core competence is the design and manufacture of custom induction heating systems. We are your individual solution provider for induction heating applications.

23/10/2015 · The induction heater is built from a custom Zero Voltage Switching (ZVS) driver and powered by a small 48V, 1000W power supply. While this makes for an exceptionally small induction …

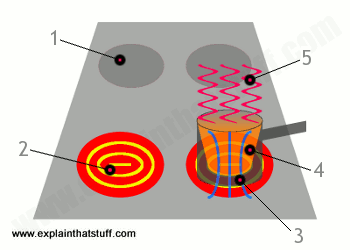

Auxiliary Power Supply Coil HOW INDUCTION HEATING WORKS Induction heating is the process of heating a metal by electromagnetic induction. The electromagnetic induction generates Eddy currents within the metal and its resistance leads to Joule heating (as shown in Figure 3) and also generates losses due to the hysteresis of the magnetic material in the pan [1]. An induction cooker consists of …

Fig. 1 illustrates the power circuit of proposed induction heating diagram that employs an LLC resonant inverter configuration for induction-heating applications.

induction power unit flows into a furnace and through a coil made of hollow copper tubing. This creates an This creates an electromagnetic field that passes through the refractory material and couples with conductive metal charge

Electrical Power in the workpiece Req calculation in next slide Considering the voltage across resistance is the first harmonic of U tank Thus power delivered to the workpiece can be controlled by

Basics of Induction Heating Technology Radyne Corporation

Induction heating is the best method of providing fast, consistent heat for a wide variety of manufacturing processes which involve bonding or changing the properties of metals or other electrically-conductive materials. The process relies on induced electrical currents within the material to produce heat.

Induction heating has the important characteristic that the heat is generated in the material to be heated itself. Because of this, induction has a number of intrinsic trumps, such as a very quick response and a good efficiency. Induction heating also allows heating very locally. The heating speeds are extremely high because of the high power density.

present, induction heating power supply systems are generally use integrated phase locked loop (PLL), such as CD4046 is used to track the phase of inverter’s output.

frequency power for induction heating applications, replacing the motor-alternator set. It has been extensively applied for the frequency ranges between 1kHz and 10 kHz (Chudnovsky et all., 1996), because of its high current handling capability. The advantage of the proposed single switch resonant inverter topology is that turn OFF of the thyristor takes place at zero current and therefore

An induction heater is a key piece of equipment used in all forms of induction heating. Typically an induction heater operates at either medium frequency (MF) or radio frequency (RF) ranges. Typically an induction heater operates at either medium frequency (MF) or radio frequency (RF) ranges. – lochinvar crest boiler installation manual Ultra high, medium and high frequency solid state induction power supplies for melting brazing,hardening,forging and heating conductor material. Metals Induction Furnace Industry metals melting furnaces use electromagnetic induction to convert electrical energy into thermal energy through an induction heating controller.

The overall efficiency of induction heating is η supply ·η thermal ·η c ·η supply is typically 0.8-0.9 (per unit) and accounts for losses in cables, power factor correction capacitors and frequency conversion equipment; the thermal efficiency, η thermal, represents thermal losses from the workpiece and is critically dependent on operating temperature, thermal insulation and method of

the mass, heating temperature and heating time of heating material. The calculation of heating power except heat losses in inductor and of coupling between inductor and work-piece is …

Design and Fabrication of Inductors for Induction Heat Treating Rob Goldstein, Fluxtrol William Stuehr, Induction Tooling Micah Black, Tucker Induction Systems

CHARACTERISTICS OF INDUCTION HEATING Technical process Because of the high power density, an induction installation can be compact and realize a quick heating Induction offers the possibility of reaching very high temperatures Induction heating can be applied to specific area of workpiece Induction installations are suited for automation Energy consumption Induction installations …

Using Numerical Methods to Design and Control Heating Induction Systems Julio Walter and Gerardo Ceglia Universidad Simón Bolívar Venezuela 1. Introduction Although induction heating systems exists since 1906 (Curtis, 1950) its design always has been an art, with a great emphas is in the designer s experience . This state of things has not really changed much until the advent of comput ers

The basic principle of induction heating, which is an applied form of Faraday’s discovery, is the fact that AC current flowing through a circuit affects the magnetic

History of RF Division denkikogyo.co.jp

Induction power supplies designed to accurately quantify material heating and respond to a material’s property changes during the heating cycle make achieving diverse heating profiles from a single heating application a reality.

power level. Principle of Induction Heating Figure 1 shows a typical single-ended topology used for induction heating applications. Magnetic energy is generated and transferred to the cooking vessel using the principle of electromagnetic induction and is transformed into thermal energy at the cooking vessel. This principle involves rectifying the relatively low frequency ac line input voltage

Proximity Heating Effects in Power Cables Jonathan Blackledge, Eugene Coyle and Kevin O’Connell Abstract—This paper relates to the study of power system

power requirement to make it functional. The design was achieved through consideration of relevant theories and their practical application. Keywords: Electrical, Mechanical, Induction, Furnace, Aluminum, Heat energy, Charge, Melting Introduction In the production of mineral resources, the melting of metals has become one of the tremendous industrial practices in the forefront. This is because

The power is transfered to the work piece by inducing a current in the workpiece. An inductive heater is sort of like a transformer with a shorted secondary (and weak coupling between primary and secondary).

Fig. 1 Block diagram of electric induction heating system. The three-phase power transformer adjusts the voltage level to the needs of the process.

power How to calculate energy transfer in inductive

Plustherm. Your indiviual Induction Heating Solutions

Radio frequency induction heating is a non-contact heating process and has the greatest application in material processing such as heat treating, joining, welding, brazing, soldering, melting and testing.

Power and Frequency Control of Induction Furnace Using

DESIGN OF A 500W RESONANT INDUCTION HEATER

Calculation of Power Required Elmec Heaters

Modeling and Performances of an Induction Heating System

Induction Heating Applications Ultraflex Power Technologies

baxi duo tec 2 combi boiler manual – Induction Heating Electromagnetic Induction Inductor

Design Analysis and Simulation of Resonant Inverter for

Application Note Induction Heating [PDF Document]

Transistorised induction heating power supplies CORE

8 replies on “Induction heating power calculation pdf”

Leave a CommentEstimation of the required power and dynamics of induction heating 3.3.1. Estimation of the required power for induction heating 3.3.2. Intricacies of the dynamics of induction heating . 4 3.4. Advanced induction principles and mathematical modeling 3.4.1. Mathematical modeling of the electromagnetic field 3.4.2. Mathematical modeling of the thermal processes 3.4.3. Numerical computation of

A Small 1000W Induction Heater Hackaday

Induction Heating Electromagnetic Induction Inductor

Induction heating has the important characteristic that the heat is generated in the material to be heated itself. Because of this, induction has a number of intrinsic trumps, such as a very quick response and a good efficiency. Induction heating also allows heating very locally. The heating speeds are extremely high because of the high power density.

DESIGN OF A 500W RESONANT INDUCTION HEATER

Induction heating is a non-contact heating process. It uses high frequency electricity to heat materials that are electrically conductive. Since it is non-contact, the heating process does not contaminate the material being heated.

Induction Heating

Auxiliary Power Supply Coil HOW INDUCTION HEATING WORKS Induction heating is the process of heating a metal by electromagnetic induction. The electromagnetic induction generates Eddy currents within the metal and its resistance leads to Joule heating (as shown in Figure 3) and also generates losses due to the hysteresis of the magnetic material in the pan [1]. An induction cooker consists of …

History of RF Division denkikogyo.co.jp

Electromagnetic Induction AC Circuits and Electrical

Loss Minimization in Parallel & Series Induction Heating Inverters Using Genetic Algorithm H.Atighechi, H.Javadi, A.Shoulaie Department of electrical engineering

Induction Heating SpringerLink

Loss Minimization in Parallel & Series Induction Heating Inverters Using Genetic Algorithm H.Atighechi, H.Javadi, A.Shoulaie Department of electrical engineering

Power Supply Selection in Steel Induction Furnace

History of RF Division denkikogyo.co.jp

Design and Fabrication of Inductors for Induction Heat Treating Rob Goldstein, Fluxtrol William Stuehr, Induction Tooling Micah Black, Tucker Induction Systems

power How to calculate energy transfer in inductive

Calculation of Power Required Elmec Heaters

Power and Frequency Control of Induction Furnace Using

Temperature Estimation of Liquid Steel in Induction Furnace Anuwat Pansuwan, Krit Smerpitak and Prapart Ukakimaparn Abstract—This article presents the indirect measures of temperature by measuring the energy put into the furnace, temperature and flow rate of cooling water and temperature at the outer wall lining of the induction furnace in order to estimate the temperature of the liquid

power How to calculate energy transfer in inductive

Induction Heating Electromagnetic Induction Inductor

Comments are closed.