Steam boiler control system pdf

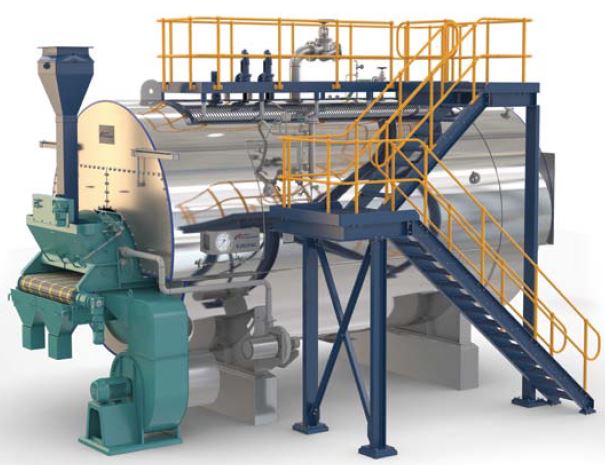

START-UP AND OPERATION STEAM BOILERS WARNING: CONTROL The steam pressure in the boiler is regulated by the Boiler Operator. This is a pressure control which senses the steam pressure and turns the boiler on and off accordingly. This control must be operationally tested. Adjust the pressure setting on the control to a pressure less than the boiler pressure (as shown on the boiler …

A. NFPA 85 Boiler and Combustion Control Systems Hazards code. B. API 556 Instrumentation and Controls for Fire Heaters and Steam Generators C. AS 3814 …

ENGINEERING FOR RURAL DEVELOPMENT Jelgava, 23.-24.05.2013. 399 SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM FOR STEAM BOILER Andris Sniders, Toms Komass

Boiler Control System Engineering introduction Boilers are a key power source for electrical generation in the United States and around the world and for providing heat in process industries and buildings.

opment of the DCS (distributed control systems or digital control systems) and electronic systems, it was the responsibility of the operator to line up the set point and the process variable before transferring to automatic control.These systems have the capability of the

Electronic steam boiler controls Important note Under many local regulations, boilers using this system for 1st and 2nd low water alarms must be supervised, and the alarms tested daily.

Surface blow down (TDS) control system for boiler Is the ultimate goal of any steam system and it includes all the heat transfer systems and functions In the case of Kiln Drying, it would provide the heat for drying and the steam for humidification. New England Kiln Drying Association – Steam Design & Best Practices – HerLine Technologies GAUGE ABSOLUTE TEMP SENSIBLE LATENT TOTAL

combustion control the steam demand from boiler varythe steam demand from boiler vary depending upon change in process requirement or power requirement. the fuel fed to the boiler should be controlled tofed to the boiler should be controlled to give the necessary quantity of steam. the steam demand increase or decrease will be indicated by the boiler outlet pressureindicated by the boiler

• Boiler operators of larger steam systems like to have two boilers online and contributing to the load in some way • Increases reliability and helps the equipment last longer.

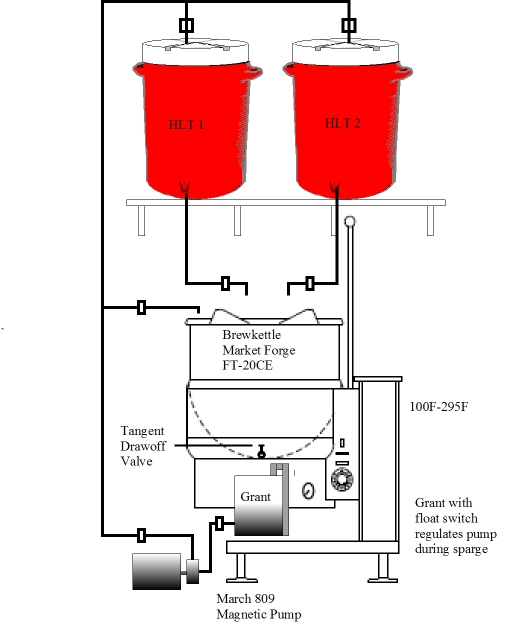

Automated control systems, such as in either the boiler or steam-condensate system. Boiler Feedwater A boiler’s efficiency is directly related to the quality of its feedwater. The feedwater system refers to deaerator, feedwater pumps, and the piping to the boiler. Before water enters the boiler, oxygen must be removed or corrosion can occur throughout the boiler system, forming pits that

Complex boiler control systems may involve multiple digital control systems (e.g. DCS, PLC, or computer controlled smart instruments) linked together by a communication data bus.

The boiler operating control is set at the desired steam pressure of the boiler. On-off steam systems for comfort heating are usually set for an average of 2 lb. of steam pressure. The operating control is an automatic one that will cycle the boiler between the settings of the pressure control as long as there is a call for heat. For example, you could set the control for 3 psig with a 2-lb

the nonlinearity of the system for accurate control of the boiler steam temperature and pressure level. Embedded system based boiler automation system consist of GSM (Global System for Mobile Communication), PIC (Peripheral Interface Controller) and different sensors which is capable of monitoring the entire boiler temperature and obtained temperature and pressure measured data are …

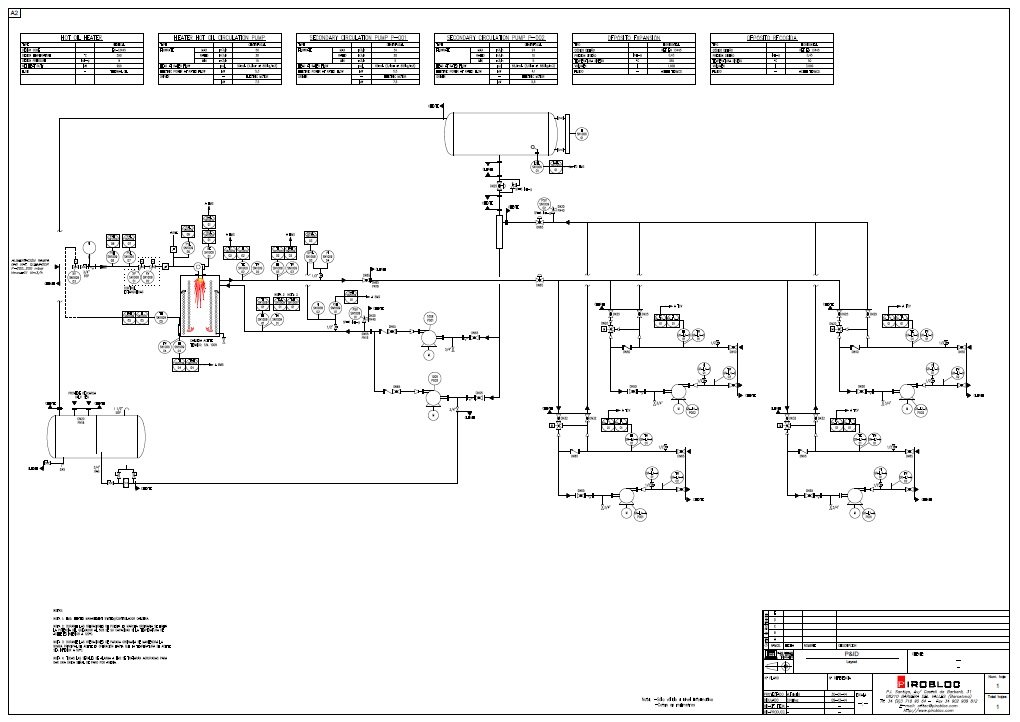

The boiler control system shall consist of both a Combustion Control System (CCS) and a Burner Management System (BMS). The CCS shall control the boiler’s fuel and air levels and drum water levels. The BMS shall control the burner startup and shutdown sequencing and all boiler safety systems. B. The specification defines the requirements for the assembled and tested hardware, …

boiler(s), main boiler control console (if any), steam engines, maneuvering platform, main boiler auxiliaries, and auxiliary boilers and boiler controls. Requirements for Oil Fired Boiler Control Systems (refer to 46 CFR 62.35-

The feedwater control system is a three element type, designed to monitor changes in steam flow, water flow and drum level. Steam flow is the rate of steam leaving the boiler – the demand. Water flow is the rate of feedwater flow into the boiler – the supply. Drum level reflects the amount of water in the boiler – the inventory. With changes in boiler load (steam flow), steam and water flow

Boilers usually form part of a larger steam system. Steam is also used for heating applications in industrial processes to control temperatures and pressures, to remove contaminants and drive mechanical processes.

• The Boiler Pressure Control System has a role in limiting the potential swell and shrink of the HTS inventory by maintaining the HTS average temperature essentially constant over the full operating range. • To control the boiler pressure, (the controlled variable) the following manipulated variables are used: (a) Reactor Power (b) Turbine Steam Flow (c) Steam Reject Valve (SRV) Steam

Boiler Control System SELMA Ship Electric Marine Control

(PDF) Boiler gas burner management system automation using PLC

The boiler system comprises of: feed water system, steam system and fuel system. The feed water system provides water to the boiler and regulates it automatically to meet the steam

The control system not only makes the Stack-boiler in the optimal combustion state, but also realizes the real-time online monitoring of the Stack-boiler, and realizes the economic, environmental

Power boilers are defined as boilers that generate steam at pressures in excess of 15 psig, for external use. Most designers and owners of steam-generation systems from fired heaters agree that ASME Code Section 1 is the appropriate design code for the steam system.

Sage2.3™ Boiler Control System Exclusive, Full Featured Boiler Control System The Sage2.3™ was designed with many features that make the control simple to understand and use, as well as features that optimize boiler performance, flexibility and overall system efficiency and reliability.

AD353-132 BOILER MASTER CONTROL With several parallel connected boilers supplying a common header, it is generally desirable to provide a way to adjust the load distribution among the boilers.

Eugen Iancu WSEAS TRANSACTIONS on SYSTEMS and CONTROL of input-output.The steam pressure p in the drum is a variable how depend on the boiler steam flow Dp and the turbine steam flow Dc. We will choose as the output variables that measurable variable how permit the obtaining a complete information on the state of the boiler in each moment of time (Fig. which to assure an efficient control …

An oxygen trim control system is installed as part of a broader digital combustion control package on a 6,350kg/hr steam boiler at a cost of £20,000. The boiler operates five days a week, 24 hours a day and uses 15,716,000kWh/year of gas. Trim control gives a 6.4% saving, equivalent to 1,005,824kWh/year of gas and 44,352kWh/year of electricity. At a gas price of 2.5p/kWh, you save £25,145 a

Control System Simulator for Steam Boiler Parameters CAMELIA MAICAN, MATEI VINATORU, GABRIELA CANURECI, EUGEN IANCU Department of Automation University of Craiova

Safe management of industrial steam and hot water boilers A guide for owners, managers and supervisors of boilers, boiler houses and boiler plant This is a web-friendly version of leaflet INDG436 Safe management of industrial steam and hot water boilers A guide for owners, managers and supervisors of boilers, boiler houses and boiler plant Background Accidents involving exploding boilers …

BURNERMATE TS BOILER CONTROL SYSTEM Ordering Information Ordering Information 1.Specify BurnerMate TS Control System from the table (see the following pages for system descriptions) Combustion Control Type Catalog Number Steam or Hot Water Boiler Steam ST Hot Water HW Single Point Positioning Combustion Control Triac** SPT Current* SPC Parallel Positioning Combustion Control …

PDF This paper presents an operation and control system for gas burner management of steam boiler and discuss about the system structure and implementation of smooth automatic operation using

Drum Level Control Systems are used extensively throughout the process industries and the Utilities to control the level of boiling water contained in boiler drums on process plant and help provide a constant supply of steam.

DSboiler V1.0 Boiler Control System Page 3 1. General A. This specification defines the requirements for the boiler control system. The boiler control

Advanced Review Steam power plant configuration, design, and control Xiao Wu,1 Jiong Shen,1 Yiguo Li1 and Kwang Y. Lee2∗ This article provides an overview of …

Boiler Control System is designed for marine industry implementing automation of burners and combustion system for any type of ship. SELMA implements the design, development and retrofit installation of Boiler Control Systems comprising of:

Boiler control and systems An extensive range of boiler controls and systems are available. Whether it’s a completely new boiler house plant or a simple blowdown valve replacement, Spirax Sarco will have the answer. 1. Feedtanks The Spirax Sarco feedtank is an atmospheric deaerator fully constructed in stainless steel – no rusting, no linings, coatings or joints to leak. It is fitted with a

3 4 Rotary Cup Burner Type SDR-1 45~100 0.15 Turbo Blower Trochoid Gear Pump(MDO, MGO) Trochoid Gear Pump(HFO, MDO, MGO) Combustion System

Control System Simulator for Steam Boiler Parameters CAMELIA MAICAN, MATEI VINATORU, GABRIELA CANURECI, EUGEN IANCU Department Automation University of Craiova

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 10, NO. 2, MARCH 2002 281 Fig. 1. The boiler’s steam-water system of a power plant’s 300 MW power unit.

STEAM HEATING BOILER CONTROL SYSTEM Filed Sept. 26, 1947 5 Sheets-Sheet 2 INVENTOR.’ Lam/renne IlEmTr-uml Aug. 28, 1951 L. c. SIMMONS STEAM HEATING BOILER CONTROL SYSTEM 5 Sheets-Sheet 5 Filed Sept. 26, 1947 JNVENTOR: awrene E Elmmuns,

Hawk 4000 1 HAWK 4000 Integrated Boiler Control System The Hawk 4000 is a state-of-the-art boiler control system that integrates the functions of a Programmable Controller and Burner Management Controller, as well

The energy efficiency of steam systems can be improved by improving the efficiency of boilers and the reticulation system, point of use equipment and control systems used throughout the process. There are many strategies to improve the efficiency by which steam is generated from boilers, such as:

Introduction to Boiler Control Systems CED Engineering

• Recognise and understand typical boiler control diagrams and their design intentions • Contribute to the setting up and tuning of boiler control loops • Identify the principles and design concepts governing: – Boiler feed water control – Furnace draft measurement and control – Steam demand and firing rate control – Main steam and reheat steam temperature control – Flue gas analysis and

Burner Management System – That portion of a boiler control system associated with the supply of fuel to the burners. This includes the complete fuel train, safety shut-off valves, fuel pressure and temperature limits, burner starting and sequencing logic and annunciation of trouble signals. Carryover – The moisture and entrained solids forming the film of steam bubbles, a result of foaming in

sure control, mechanical drive, and component separation, The distribution system carries steam from the boiler or generator to the points of end use. Many distribution sys- tems have several take-off lines that operate at different pressures. These distribution lines are separated by various types of isolation valves, pressure-regulating valves, and, sometimes, backpressure turbines. A

Boiler-Tuning Basics, Part I – powermag.com. 2009-1-3 · On my first project as a combustion control engineer, I was responsible for loop checks and for watching the experts tune the system controls.

level control system tightly controls the level whatever the disturbances, level change, increase/decrease of steam demand, feed water flow variations appears.

HC900 Boiler Control 2 The objective of the drum level control system is to maintain the water-steam interface at the specified level and provide a – water tube boiler parts and functions pdf Structural and Behavioral Models of the Steam-Boiler Control System Robert Busso w and Matthias Weber Technische Universit at Berlin January 22, 2010

9 CONTROL VALVE, (if supplied) A fully modulating temperature regulator (also referred to as a control valve) should be installed to regulate the flow of boiler water through the heating coil.

Model HAWK Integrated Boiler Control System HAWK INTEGRATED BOILER CONTROL SYSTEM . The HAWK is a state-of-the-art boiler control system that integrates the functions of a Programmable Controller and Burner Management Controller, as well as other boiler operating and ancillary controls. The HAWK system incorporates a graphical Human Machine Interface (HMI), which displays boiler …

The heart of an industrial boiler system is a hot water or steam boiler operated with a certain kind of fuel. The boiler heats up or evaporates the water inside it, which is then transported to the consumers via pipe systems. In case of hot water the transport energy is generated by pumps, in case of steam the transport is based on inherent pressure. The cooled water or the condensed steam

New boiler control system means big savings in commercial space heating your community energy company printed on recycled paper GS1660 07/25/2011 Are you ready to take a big bite out of your hot water space-heating costs without replacing your boiler? If your annual natural gas heating/reheating fuel bills are greater than ,000, a new control system offers you an excellent chance of

International Journal of Instrumentation and Control Systems (IJICS) Vol.4, No.2, April 2014 3 Measurement of boiler steam drum level using differential pressure transmitter must take into

Tuning of drum level control on a 600 MW natural circulation boiler with a steam driven feedpump is extremely difficult due to the drum level instability. While it is hard to generalize. This would require extended range feedwater flow measurement (two stacked transmitters. It pays to get the drum level control tuning as perfect as possible. Stability of any boiler will benefit from lagging

The main components ofthe boiler pressure control system are outlined in Figure 3. The steam pressure is The steam pressure is sensed by electronic transmitters which develop the measurement signal for the boiler pressure control

The control system for a boiler–turbine unit usually needs to meet the requirement of the amount of water in the steam drum must be maintained at a desired level to prevent overheating of the drum or flooding of steam lines.

Three Element Feed Control System

New Boiler Control System Madison Wisconsin

coal fired boiler logic control CFB power plant boiler

Complete Boiler System Federal Corporation

US2566041A Steam heating boiler control system – Google

Boiler Control Systems U.S. Boiler Company

CHAPTER 3 STEAM GENERATOR CONTROL MODULE 2 PRESSURE CONTROL

SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM

– How to implement oxygen trim control Carbon Trust

BURNERMATE TS BOILER CONTROL SYSTEM Overview

Modeling and Simulation of prototype of boiler drum level

“Standards Compliance and User Requirements for Industrial

40 replies on “Steam boiler control system pdf”

Leave a CommentNew boiler control system means big savings in commercial space heating your community energy company printed on recycled paper GS1660 07/25/2011 Are you ready to take a big bite out of your hot water space-heating costs without replacing your boiler? If your annual natural gas heating/reheating fuel bills are greater than ,000, a new control system offers you an excellent chance of

Control System Simulator for Steam Boiler scribd.com

Eugen Iancu WSEAS TRANSACTIONS on SYSTEMS and CONTROL of input-output.The steam pressure p in the drum is a variable how depend on the boiler steam flow Dp and the turbine steam flow Dc. We will choose as the output variables that measurable variable how permit the obtaining a complete information on the state of the boiler in each moment of time (Fig. which to assure an efficient control …

Boiler Control System SELMA Ship Electric Marine Control

BoilerTuning.pdf Boiler Control System Scribd

4 things to look out for in steam boiler pressure controls

Complex boiler control systems may involve multiple digital control systems (e.g. DCS, PLC, or computer controlled smart instruments) linked together by a communication data bus.

Process heat boilers and steam systems Energy EXchange

The control system not only makes the Stack-boiler in the optimal combustion state, but also realizes the real-time online monitoring of the Stack-boiler, and realizes the economic, environmental

How to implement oxygen trim control Carbon Trust

Boiler Control Systems U.S. Boiler Company

The main components ofthe boiler pressure control system are outlined in Figure 3. The steam pressure is The steam pressure is sensed by electronic transmitters which develop the measurement signal for the boiler pressure control

CHAPTER 3 STEAM GENERATOR CONTROL MODULE 2 PRESSURE CONTROL

Boiler Control System Engineering boilersinfo.com

New Boiler Control System Madison Wisconsin

PDF This paper presents an operation and control system for gas burner management of steam boiler and discuss about the system structure and implementation of smooth automatic operation using

(PDF) Automatic control of boiler system using distributed

The boiler control system shall consist of both a Combustion Control System (CCS) and a Burner Management System (BMS). The CCS shall control the boiler’s fuel and air levels and drum water levels. The BMS shall control the burner startup and shutdown sequencing and all boiler safety systems. B. The specification defines the requirements for the assembled and tested hardware, …

MSC Guidelines for Boiler Control System dco.uscg.mil

Advanced Review Steam power plant configuration, design, and control Xiao Wu,1 Jiong Shen,1 Yiguo Li1 and Kwang Y. Lee2∗ This article provides an overview of …

Drum Level Control Systems Guide in the Process Industries

Structural and Behavioral Models of the Steam-Boiler

New Boiler Control System Madison Wisconsin

Drum Level Control Systems are used extensively throughout the process industries and the Utilities to control the level of boiling water contained in boiler drums on process plant and help provide a constant supply of steam.

CHAPTER 3 STEAM GENERATOR CONTROL MODULE 2 PRESSURE CONTROL

The boiler control system shall consist of both a Combustion Control System (CCS) and a Burner Management System (BMS). The CCS shall control the boiler’s fuel and air levels and drum water levels. The BMS shall control the burner startup and shutdown sequencing and all boiler safety systems. B. The specification defines the requirements for the assembled and tested hardware, …

Control System Simulator for Steam Boiler Parameters

Control System Simulator for Steam Boiler scribd.com

Advanced Review Steam power plant configuration, design, and control Xiao Wu,1 Jiong Shen,1 Yiguo Li1 and Kwang Y. Lee2∗ This article provides an overview of …

4 things to look out for in steam boiler pressure controls

The boiler operating control is set at the desired steam pressure of the boiler. On-off steam systems for comfort heating are usually set for an average of 2 lb. of steam pressure. The operating control is an automatic one that will cycle the boiler between the settings of the pressure control as long as there is a call for heat. For example, you could set the control for 3 psig with a 2-lb

SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM

The energy efficiency of steam systems can be improved by improving the efficiency of boilers and the reticulation system, point of use equipment and control systems used throughout the process. There are many strategies to improve the efficiency by which steam is generated from boilers, such as:

Technology background – Process heat boilers and steam

New boiler control system means big savings in commercial space heating your community energy company printed on recycled paper GS1660 07/25/2011 Are you ready to take a big bite out of your hot water space-heating costs without replacing your boiler? If your annual natural gas heating/reheating fuel bills are greater than ,000, a new control system offers you an excellent chance of

US2566041A Steam heating boiler control system – Google

International Journal of Instrumentation and Control Systems (IJICS) Vol.4, No.2, April 2014 3 Measurement of boiler steam drum level using differential pressure transmitter must take into

4 things to look out for in steam boiler pressure controls

Control System Simulator for Steam Boiler Parameters CAMELIA MAICAN, MATEI VINATORU, GABRIELA CANURECI, EUGEN IANCU Department of Automation University of Craiova

US2566041A Steam heating boiler control system – Google

“Standards Compliance and User Requirements for Industrial

HAWK 4000 Integrated Boiler Control System cleaverbrooks.com

Safe management of industrial steam and hot water boilers A guide for owners, managers and supervisors of boilers, boiler houses and boiler plant This is a web-friendly version of leaflet INDG436 Safe management of industrial steam and hot water boilers A guide for owners, managers and supervisors of boilers, boiler houses and boiler plant Background Accidents involving exploding boilers …

Control System Simulator for Steam Boiler Parameters

Complete Boiler System Federal Corporation

AD353-132 BOILER MASTER CONTROL With several parallel connected boilers supplying a common header, it is generally desirable to provide a way to adjust the load distribution among the boilers.

HC900 Boiler Control Honeywell

Intelligence-Based Hybrid Control for Power Plant Boiler

COMBUSTION CONTROL SYSTEM dieselduck.info

Electronic steam boiler controls Important note Under many local regulations, boilers using this system for 1st and 2nd low water alarms must be supervised, and the alarms tested daily.

Modeling and Simulation of prototype of boiler drum level

STEAM HEATING BOILER CONTROL SYSTEM Filed Sept. 26, 1947 5 Sheets-Sheet 2 INVENTOR.’ Lam/renne IlEmTr-uml Aug. 28, 1951 L. c. SIMMONS STEAM HEATING BOILER CONTROL SYSTEM 5 Sheets-Sheet 5 Filed Sept. 26, 1947 JNVENTOR: awrene E Elmmuns,

Boiler Control System SELMA Ship Electric Marine Control

Technology background – Process heat boilers and steam

BOILER CONTROL AND INSTRUMENTATION automation.com

The boiler operating control is set at the desired steam pressure of the boiler. On-off steam systems for comfort heating are usually set for an average of 2 lb. of steam pressure. The operating control is an automatic one that will cycle the boiler between the settings of the pressure control as long as there is a call for heat. For example, you could set the control for 3 psig with a 2-lb

HC900 Boiler Control Honeywell

Safe management of industrial steam and hot water boilers A guide for owners, managers and supervisors of boilers, boiler houses and boiler plant This is a web-friendly version of leaflet INDG436 Safe management of industrial steam and hot water boilers A guide for owners, managers and supervisors of boilers, boiler houses and boiler plant Background Accidents involving exploding boilers …

Procidia Control Solutions Boiler Control Overview

The boiler system comprises of: feed water system, steam system and fuel system. The feed water system provides water to the boiler and regulates it automatically to meet the steam

HAWK INTEGRATED BOILER CONTROL SYSTEM Ontario

Three Element Feed Control System

HC900 Boiler Control 2 The objective of the drum level control system is to maintain the water-steam interface at the specified level and provide a

SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM

9 CONTROL VALVE, (if supplied) A fully modulating temperature regulator (also referred to as a control valve) should be installed to regulate the flow of boiler water through the heating coil.

Boiler Control Systems Engineering Second Edition Chapter 2

coal fired boiler logic control CFB power plant boiler

Structural and Behavioral Models of the Steam-Boiler

combustion control the steam demand from boiler varythe steam demand from boiler vary depending upon change in process requirement or power requirement. the fuel fed to the boiler should be controlled tofed to the boiler should be controlled to give the necessary quantity of steam. the steam demand increase or decrease will be indicated by the boiler outlet pressureindicated by the boiler

Boiler Control System SELMA Ship Electric Marine Control

HAWK 4000 Integrated Boiler Control System cleaverbrooks.com

The main components ofthe boiler pressure control system are outlined in Figure 3. The steam pressure is The steam pressure is sensed by electronic transmitters which develop the measurement signal for the boiler pressure control

BURNERMATE TS BOILER CONTROL SYSTEM Overview

HC900 Boiler Control Honeywell

Procidia Control Solutions Boiler Control Overview

BURNERMATE TS BOILER CONTROL SYSTEM Ordering Information Ordering Information 1.Specify BurnerMate TS Control System from the table (see the following pages for system descriptions) Combustion Control Type Catalog Number Steam or Hot Water Boiler Steam ST Hot Water HW Single Point Positioning Combustion Control Triac** SPT Current* SPC Parallel Positioning Combustion Control …

Technology background – Process heat boilers and steam

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 10, NO. 2, MARCH 2002 281 Fig. 1. The boiler’s steam-water system of a power plant’s 300 MW power unit.

Design Specification For Boiler Control System PDF Free

HAWK INTEGRATED BOILER CONTROL SYSTEM Ontario

New Boiler Control System Madison Wisconsin

HC900 Boiler Control 2 The objective of the drum level control system is to maintain the water-steam interface at the specified level and provide a

coal fired boiler logic control CFB power plant boiler

ENGINEERING FOR RURAL DEVELOPMENT Jelgava, 23.-24.05.2013. 399 SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM FOR STEAM BOILER Andris Sniders, Toms Komass

BoilerTuning.pdf Boiler Control System Scribd

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 10, NO. 2, MARCH 2002 281 Fig. 1. The boiler’s steam-water system of a power plant’s 300 MW power unit.

Modeling and Simulation of prototype of boiler drum level

“Standards Compliance and User Requirements for Industrial

SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM

ENGINEERING FOR RURAL DEVELOPMENT Jelgava, 23.-24.05.2013. 399 SIMULATION OF MULTI-LINK INVARIANT CONTROL SYSTEM FOR STEAM BOILER Andris Sniders, Toms Komass

4 things to look out for in steam boiler pressure controls

Boiler Control Systems Engineering Second Edition Chapter 2

AD353-132 BOILER MASTER CONTROL With several parallel connected boilers supplying a common header, it is generally desirable to provide a way to adjust the load distribution among the boilers.

(PDF) Boiler gas burner management system automation using PLC

New boiler control system means big savings in commercial space heating your community energy company printed on recycled paper GS1660 07/25/2011 Are you ready to take a big bite out of your hot water space-heating costs without replacing your boiler? If your annual natural gas heating/reheating fuel bills are greater than ,000, a new control system offers you an excellent chance of

BOILER CONTROL AND INSTRUMENTATION automation.com

DSboiler V1.0 Boiler Control System Page 3 1. General A. This specification defines the requirements for the boiler control system. The boiler control

Procidia Control Solutions Boiler Control Overview

Hawk 4000 1 HAWK 4000 Integrated Boiler Control System The Hawk 4000 is a state-of-the-art boiler control system that integrates the functions of a Programmable Controller and Burner Management Controller, as well

Boiler Control Systems Engineering Second Edition Chapter 2

Advanced Review Steam power plant configuration, design, and control Xiao Wu,1 Jiong Shen,1 Yiguo Li1 and Kwang Y. Lee2∗ This article provides an overview of …

HC900 Boiler Control Honeywell

Control System Simulator for Steam Boiler Parameters CAMELIA MAICAN, MATEI VINATORU, GABRIELA CANURECI, EUGEN IANCU Department Automation University of Craiova

PLC & SCADA Based Effective Boiler Automation System for

9 CONTROL VALVE, (if supplied) A fully modulating temperature regulator (also referred to as a control valve) should be installed to regulate the flow of boiler water through the heating coil.

Applying ASME Boiler Code to Steam Generation Systems

Intelligence-Based Hybrid Control for Power Plant Boiler

Comments are closed.