Types of high pressure boilers pdf

can find low pressure boilers 4th edition steingress or just about any type of ebooks, for any type of product. Download: LOW PRESSURE BOILERS 4TH EDITION STEINGRESS PDF Best of all, they are entirely free to find, use and download, so there is no cost or stress at all. low pressure boilers 4th edition steingress PDF may not make exciting reading, but low pressure boilers 4th edition

The high pressure boiler which is also known as modern boilers used for power generation are for steam capacities 30 to 650 tons/hr and above with a pressure up to 160 bar and maximum steam temperature of about 540°C.

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

Three pass full wetback, packaged firetube type, constructed in accordance with requirements of the ASME Code Section IV for 30 psi and 125 psi water or 15 psi steam; Section I for higher pressure steam. All units are registered with the National Board. Boiler tubes are expanded and flared in low pressure boilers; expanded and beaded in high pressure boilers. Turbulator baffles are not used in

Boilers are high pressure and temperature systems used for generating steam to drive steam turbines for electricity generation. If, due to any reason of operation or malfunction in equipment or controls, the operating pressure in the system goes above the safe limit of …

medium is high pressure overfire air. This economic arrangement allows for a boiler This economic arrangement allows for a boiler uprate without the additional cost of rearranging the boiler pressure …

pressure in the high subcritical and supercritical range. In this type the feedwater goes through the economizer, furnace walls and super heater sections in one continuous pass, so no

critical boilers are once through boilers where water pumped in at pressure by the Boiler Feed Pump passes progressively through the heating stages of the boiler and is delivered to the turbine at final temperature with no recirculation.

the Parat water tube boiler is a fully automatic steam boiler. a well dimensioned steam drum make the boiler suitable for evaporating steam from other exhaust gas boilers.the design and performance is a result of solid experience and high

The blowdown amount required is a function of boiler type, steam pressure, chemical treatment program, and feedwater quality. The optimum blowdown amount is typically calculated and controlled by measuring the conductivity of the boiler feedwater. Conductivity is a viable indicator of the overall total dissolved solid concentrations. Typically, blowdown rates range from 4 – 8 percent of

* water converted into high pressure steam by transfer of heat from very high temperature combustion gases on water. * hot combustion gases produced by burning diesel oil, town gas etc. in the furnace. * boilers are of fully automatic design. * essential mountings include safety valve, steam pressure switch, pressure gauge, gauge glass, valve fittings, low-water level cut-off and alarm devices

Boilers that operate higher than 15 psig are called “high-pressure” boilers. A hot water boiler, strictly speaking, is not a boiler. It is a fuel-fired hot water heater. Because of its similarities in many ways to a steam boiler, the term ”hot water boiler” is used. Hotwater boilers that have temperatures above 250° Fahrenheit or pressures higher than 160 psig are called ”high temperature

the following books are helpful in preparing for the boiler operator examination: high pressure examination: high pressure boilers by fredrick m. steingress .00 + s/h

Difference Between Low- and High-Pressure Boilers Hunker

150 PSI High Pressure Steam Boilers Atmospheric / Natural

Industrial boiler systems can cope with much higher pressures than pressure cookers. These boilers are welded from thick steel plates that are up to 35 mm thick, making pressures of 30 bar and more possible. A stable, robust design is also essential – if a boiler of this type were to collapse, explosive forces comparable to the explosive power of a ton of gelignite would be released (milk

Boilers are classified by their pressure capacity, their design type and by their use. High & Low Pressure Boilers – The M.A.W.P or Maximum Allowable Working Pressure is the highest amount of pressure that the vessel is designed to withstand. Pressure is measured in terms of pounds per square inch or psi. Psig (gauge) indicates gauge pressure, which ignores the atmospheric pressure. Psia

xVery high pressure boilers, from above 1200 psig to supercritical pressures (section 5.3.4) are found in large power generation stations. They require the highest

Fairfield-Johnson boiler: a later form of Johnson boiler operating at lower pressure (450psi rather than 850psi), but still a high superheat temperature 825 °F (441 °C). [4] Fairlie boiler : A double-ended locomotive boiler with a central firebox, used in Fairlie’s patent for …

A boiler is a vessel in which water is heated under pressure and vaporized into steam for a specific purpose. There are several different kinds of boilers, heated by coal, solid fuel, oil or gas.

parts of tank-type boilers, where such parts are in compression. In this chapter details of the construction of riveted, welded and forged boilers will be given, and also particulars of require

Every type of steel tube and pipe can be manufactured. A power generation boiler consists of an economizer, a furnace( evapo-rator), a superheater tube, a reheater tube, a main steam pipe, a reheat

cibo energy efficiency handbook council of industrial boiler owners (cibo) 6035 burke centre parkway, suite 360 burke, va 22015 edited by ronald a. zeitz

I of the ASME Boiler and Pressure Vessel Code.2 These rules apply to steam boilers that operate above 15 psig and hot water boilers that operate above 160 psig or 250°F. Common design pressures are 150, 200, 250, and 300 psig, but higher pressures are possible. 3 For example, boilers for certain pulp and paper industry applications are now designed for pressures as high as 1,500 psig

There are two main types of boilers, based on the type of heat transfer system they use: Firetube boilers – store water in the main body of the boiler. They heat the water via conduction where a tube carrying the combustion gases is immersed in water. Firetube boilers are simple and low cost and best suited to producing hot water or low pressure steam. Watertube boilers – Combust fuel in a

High efficiency – High-pressure boilers have better firing methods, monitoring, furnace conditions, control flue gases and water velocity. Intensive heating – the furnace temperature in high-pressure boilers is high enough and therefore, 70% of heat is transferred to water by radiation.

• High Pressure up to 900 psig • Fast Steaming • Low Water Content • Quick Response to Load Demands • Disadvantages • Steam Only • Process Only 32. 17 Types of Boilers • Cast Iron Sectional • Scotch Marine Steel • Firetube • Firebox • Watertube • Low water content copper fin • Condensing boilers 33 Boiler Type Copper Fin Tube – Horizontal Lay-out 34 Source

Boilers: Types, Combustion in boilers, Performances evaluation, Analysis of losses, Feed water treatment, Blow down, Energy conservation opportunities. 2.1 Introduction A boiler is an enclosed vessel that provides a means for combustion heat to be transferred into water until it becomes heated water or steam. The hot water or steam under pressure is then usable for transferring the heat to a

ME 416/516 Introduction There is a tremendous variation in boiler design and size- ranging from home heating size of capacity less than 100 Ibm/hr of steam to utility boilers in excess of

One of the reasons is that a boiler using this type of combustion allows many different types of fuels, also lower quality fuels, to be used in the same boiler with high combustion efficiency.

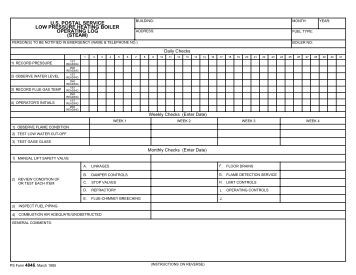

In addition to the checks and tests listed on the High-Pressure Power Boiler Log – Weekly (form 1467) or High-Pressure Power BoilerLog – Hourly (form 2055) log sheets, the following checks should be made on a periodic basis.

High Pressure Boilers Fire tube boilers are cheaper and easier to transport at low operating pressures (<30bar) and steam generation rates less than 30000kg/hr. Above these parameters, the size of the shell becomes unwieldy to transport.

BOILER TYPES Two principal types of boilers are used for industrial applications: This is a contamination of steam with boiler water solids High concentrations of soluble or insoluble solids in boiler water can stabilize and strengthen the bubbles surface in boiler water, giving rise to foaming. Steam generated can carry the foams into the process. Substances such as oil, alkali, greases

boiler was a spirally-wound-type boiler with smooth tubes. However, this boiler had a significant However, this boiler had a significant pressure drop at the water wall tubes because its fluid mass velocity was high and the tubes were

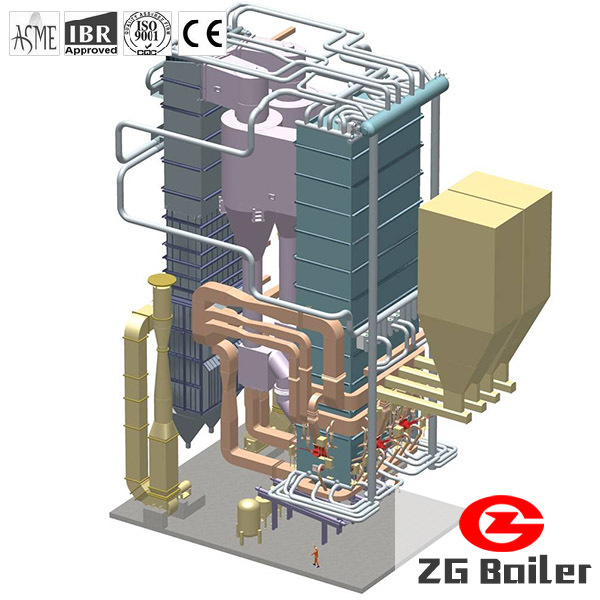

High pressure boilers (Powertherm) are mostly water tube boilers in which water is on the tube side while flue gases flow across the tubes thereby transferring heat from flue gases to …

High-Pressure Steam Cycle and Boiler Water Treatment – High purity steam to the turbine – No excess hydrate alkalinity – Precise control of total system water treatment High Pressure Boilers • Steam cycle – Begins at the boiler where thermal energy in superheated steam is converted to mechanical energy in the propulsion turbine – Steam is then converted into condensate in the

Steam and high temperature hot water (HTHW) boilers are commonly used in industrial sectors and in some applications in public and commercial organisations. They are found in circumstances where there is a continual demand for steam or hot water, in a wide range of industrial processes, such as cooking large vats of food, corrugating cardboard and chemical production amongst others. Other

High Pressure Boiler: Powertherm. High pressure boilers (Powertherm) are mostly water tube boilers in which water is on the tube side while flue gases flow across the tubes thereby transferring heat from flue gases to water using cross flow heat transfer.

High pressure Boilers Boilersinfo

Global Superheated Water High Pressure Boiler Market Research Report 2017 (1) – This report provided by GrandResearchStore is about, Superheated Water High Pressure Boiler in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with capacity, production, price

A boiler is an appliance designed to heat water and produce energy. The heat is applied to water in an enclosed container before being distributed throughout the system. The major difference between a low-pressure and a high-pressure boiler is the amount of pressure per square inch and pounds per…

have large capacity, high steam parameters, and high boiler efficiency. There are two type boilers: industrial boiler and marine boilers. a. Industrial Boiler is utilized to produce steam for electrical power generation. Normally have large capacity, high steam parameters, and high boiler efficiency. b. Marine Boiler is utilized as a source of motive power for ships. Normally compact general

Most high-pressure and large boilers are of this type (Figure 9.2.2). It is important to note that It is important to note that the small tubes in the water-tube boiler can withstand high pressure better than the large vessels of a

Section IV Heating Boilers – commercial boilers, industrial boilers, heating boilers, low pressure boilers boilers in which steam or other vapor is generated at a pressures not exceeding 15 psig high temperature water boilers intended for operation at pressures not exceeding 160 psig and or temperatures exceeding 250 degrees F

of high-pressure steam to push against moving pistons in the cylinders of reciprocating engines, or against the moving vanes of steam turbines. When the Berkeley and the Medea were built, steam piston engines, after a century of develop-ment, were universal for marine use, and they continued up through the Liberty Ships of World War II that deliberately used an old design that was easy to

dependent upon the type of boiler, the designed heat transfer surface and the fuels that power the combustion. The Basics of Steam Generation – 4 A simple boiler In order to describe the principles of a steam boiler, consider a very simple case, where the boiler simply is a container, partially filled with water (Figure 1). Combustion of fuel produce heat, which is transferred to the container

of 5 parts per billion (ppb) or lower is needed to prevent corrosion in most high- pressure (>200 pounds per square inch) boilers. While oxygen concentrations of

media other than water, steam generation by drop in pressure of high-pressure hot water within pressure reducing chambers, by transformation of mechanical (kinetic) energy into heat energy and steam generation at critical or supercritical pressure values.

Water tube boilers are used for high-pressure boilers. Fuel is burned inside the furnace, creating hot gas which heats up water in the steam generating tubes. Types of water tube boiler Babcock Wilcox boiler, Sterling boiler etc. Fig. Schematic Diagram of a Water Tube Boiler. 12 Water Tube Boiler Babcock Wilcox boiler. 13 Comparison between Water Tube and Fire Tube Boilers. Fire Tube Boiler – weil mclain gold oil boiler model wgo 3 installtion manual 2019 Whatever the type of fuel being fired, all high pressure boilers are bound to have a tube failure during the course of their working life. Did you know that a single tube failure in a 500 MW boiler requiring four days of repair work can result in a loss of more than ,000,000 apart from the generation loss?

DZL Series Coal Fired Chain Grate Boiler 2-10 t/1.4-7 MW Pressure: ≤1.6MPa SZL Assembled Chain Grate Coal Fired Boiler 6-25 t/4.2-17.5MW

Consider Installing High-Pressure Boilers with Backpressure Turbine-Generators When specifying a new boiler, consider a high-pressure boiler with a backpressure steam turbine-generator placed between the boiler and the steam distribution network. A turbine-generator can often produce enough electricity to justify the capital cost of purchasing the higher-pressure boiler and the turbine

Positive displacement pumps will discharge at the pressure required by the system they are supplying. The relief valve prevents system and pump damage if the pump discharge valve is shut during pump operation or if any other occurrence such as a clogged strainer blocks system flow.

Home / Boiler and Mechanical Digital Library / High pressure Boilers Technical papers Books pdf, presentations ppt and manuals about High pressure Boilers subcritical and supercritical Pulverized Coal utility boilers.

boiler size and power are the output steam mass flow rate, pressure and temperature. Since the first boilers were used in Since the first boilers were used in the 18 th century, the design of boilers has evolved so as to increase efficiency as well as steam pressure and temperature.

boiler in comparison with 2 pass type traditional boiler design have also been described and analyzed. Flexibility in operation of modern power stations is achieved by the Benson technology with sliding pressure, a well proven, reliable and effective operational mode. The material selection in a modern boiler, being one of the key aspects of supercritical and ultra supercritical design in the

5 BOILER AND PRESSURE VESSEL B-5.1 REG 1 CHAPTER B-5.1 REG 1 The Boiler and Pressure Vessel Act, 1999 PART I Preliminary Matters Title 1 These regulations may be cited as The Boiler and Pressure Vessel Regulations.

150 PSI High Pressure Steam Boilers Atmospheric / Natural Gas Fired PRODUCT DESCRIPTION Rite Atmospheric Natural Gas Fired High Pressure Steam Boilers have been providing our valued customers with high

Boiler Types – There are many different types of boilers in the boiler room today in a variety of heating applications. There are two main categories of boilers among the different boilers and those two categories are steam boilers and hot water boilers.

Chapter 3 Fossil-fuel steam Generators

Safety Valves in Boiler System Bright Hub Engineering

high pressure boiler Boiler Steam Engine Scribd

PPT – High Pressure Boilers PowerPoint presentation free

Boiler Wikipedia

HIGH-PRESSURE POWER BOILER LOG – WEEKLY

Technology background – Process heat boilers and steam

CIBO Energy Efficiency Handbook

example of water tube boiler – Consider Installing High-Pressure Boilers with

NY AEE BOILERS 101 (SEPT 2014) Website

OPERATING AND MAINTENANCE MANUAL FOR BOILER WATER OR HIGH

LOW PRESSURE BOILERS 4TH EDITION STEINGRESS PDF

21 replies on “Types of high pressure boilers pdf”

Leave a CommentWhatever the type of fuel being fired, all high pressure boilers are bound to have a tube failure during the course of their working life. Did you know that a single tube failure in a 500 MW boiler requiring four days of repair work can result in a loss of more than ,000,000 apart from the generation loss?

150 PSI High Pressure Steam Boilers Atmospheric / Natural

Boiler Blowdown Fact Sheet

Thermodyne Engineering Systems — High Pressure Boiler

BOILER TYPES Two principal types of boilers are used for industrial applications: This is a contamination of steam with boiler water solids High concentrations of soluble or insoluble solids in boiler water can stabilize and strengthen the bubbles surface in boiler water, giving rise to foaming. Steam generated can carry the foams into the process. Substances such as oil, alkali, greases

High Pressure Boilers.ppt Boiler Steam Scribd

Boiler Wikipedia

Boilers are classified by their pressure capacity, their design type and by their use. High & Low Pressure Boilers – The M.A.W.P or Maximum Allowable Working Pressure is the highest amount of pressure that the vessel is designed to withstand. Pressure is measured in terms of pounds per square inch or psi. Psig (gauge) indicates gauge pressure, which ignores the atmospheric pressure. Psia

Boiler Types HVAC Heating and Cooling

Safety Valves in Boiler System Bright Hub Engineering

Most high-pressure and large boilers are of this type (Figure 9.2.2). It is important to note that It is important to note that the small tubes in the water-tube boiler can withstand high pressure better than the large vessels of a

Chapter 3 Fossil-fuel steam Generators

Technology background – Process heat boilers and steam

Whatever the type of fuel being fired, all high pressure boilers are bound to have a tube failure during the course of their working life. Did you know that a single tube failure in a 500 MW boiler requiring four days of repair work can result in a loss of more than ,000,000 apart from the generation loss?

LOW PRESSURE BOILERS 4TH EDITION STEINGRESS PDF

The high pressure boiler which is also known as modern boilers used for power generation are for steam capacities 30 to 650 tons/hr and above with a pressure up to 160 bar and maximum steam temperature of about 540°C.

Technology background – Process heat boilers and steam

Consider Installing High-Pressure Boilers with

Three pass full wetback, packaged firetube type, constructed in accordance with requirements of the ASME Code Section IV for 30 psi and 125 psi water or 15 psi steam; Section I for higher pressure steam. All units are registered with the National Board. Boiler tubes are expanded and flared in low pressure boilers; expanded and beaded in high pressure boilers. Turbulator baffles are not used in

Design Technology for Supercritical Sliding Pressure

Boiler Wikipedia

the following books are helpful in preparing for the boiler operator examination: high pressure examination: high pressure boilers by fredrick m. steingress .00 + s/h

Boiler Wikipedia

Safety Valves in Boiler System Bright Hub Engineering

parts of tank-type boilers, where such parts are in compression. In this chapter details of the construction of riveted, welded and forged boilers will be given, and also particulars of require

CIBO Energy Efficiency Handbook

Boiler Types HVAC Heating and Cooling

Consider Installing High-Pressure Boilers with

Industrial boiler systems can cope with much higher pressures than pressure cookers. These boilers are welded from thick steel plates that are up to 35 mm thick, making pressures of 30 bar and more possible. A stable, robust design is also essential – if a boiler of this type were to collapse, explosive forces comparable to the explosive power of a ton of gelignite would be released (milk

Safety Valves in Boiler System Bright Hub Engineering

Every type of steel tube and pipe can be manufactured. A power generation boiler consists of an economizer, a furnace( evapo-rator), a superheater tube, a reheater tube, a main steam pipe, a reheat

Boiler Wikipedia

High Pressure Boilers.ppt Boiler Steam Scribd

Consider Installing High-Pressure Boilers with Backpressure Turbine-Generators When specifying a new boiler, consider a high-pressure boiler with a backpressure steam turbine-generator placed between the boiler and the steam distribution network. A turbine-generator can often produce enough electricity to justify the capital cost of purchasing the higher-pressure boiler and the turbine

High Pressure Boilers.ppt Boiler Steam Scribd

Three pass full wetback, packaged firetube type, constructed in accordance with requirements of the ASME Code Section IV for 30 psi and 125 psi water or 15 psi steam; Section I for higher pressure steam. All units are registered with the National Board. Boiler tubes are expanded and flared in low pressure boilers; expanded and beaded in high pressure boilers. Turbulator baffles are not used in

LOW PRESSURE BOILERS 4TH EDITION STEINGRESS PDF

Consider Installing High-Pressure Boilers with

Consider Installing High-Pressure Boilers with Backpressure Turbine-Generators When specifying a new boiler, consider a high-pressure boiler with a backpressure steam turbine-generator placed between the boiler and the steam distribution network. A turbine-generator can often produce enough electricity to justify the capital cost of purchasing the higher-pressure boiler and the turbine

CIBO Energy Efficiency Handbook

LOW PRESSURE BOILERS 4TH EDITION STEINGRESS PDF

High pressure Boilers Boilersinfo

Boilers are classified by their pressure capacity, their design type and by their use. High & Low Pressure Boilers – The M.A.W.P or Maximum Allowable Working Pressure is the highest amount of pressure that the vessel is designed to withstand. Pressure is measured in terms of pounds per square inch or psi. Psig (gauge) indicates gauge pressure, which ignores the atmospheric pressure. Psia

High Pressure Boilers Powertherm Manufacturer Water

Tube Failures in High Pressure Boilers

Technology background – Process heat boilers and steam

• High Pressure up to 900 psig • Fast Steaming • Low Water Content • Quick Response to Load Demands • Disadvantages • Steam Only • Process Only 32. 17 Types of Boilers • Cast Iron Sectional • Scotch Marine Steel • Firetube • Firebox • Watertube • Low water content copper fin • Condensing boilers 33 Boiler Type Copper Fin Tube – Horizontal Lay-out 34 Source

150 PSI High Pressure Steam Boilers Atmospheric / Natural

BOILER WATER TREATMENT Sensorex

A boiler is a vessel in which water is heated under pressure and vaporized into steam for a specific purpose. There are several different kinds of boilers, heated by coal, solid fuel, oil or gas.

Classifications of Boilers Engineering ToolBox

cibo energy efficiency handbook council of industrial boiler owners (cibo) 6035 burke centre parkway, suite 360 burke, va 22015 edited by ronald a. zeitz

High Pressure Boilers Powertherm Manufacturer Water

Boiler Types HVAC Heating and Cooling

the following books are helpful in preparing for the boiler operator examination: high pressure examination: high pressure boilers by fredrick m. steingress .00 + s/h

OPERATING AND MAINTENANCE MANUAL FOR BOILER WATER OR HIGH

Thermodyne Engineering Systems — High Pressure Boiler

Boilers that operate higher than 15 psig are called “high-pressure” boilers. A hot water boiler, strictly speaking, is not a boiler. It is a fuel-fired hot water heater. Because of its similarities in many ways to a steam boiler, the term ”hot water boiler” is used. Hotwater boilers that have temperatures above 250° Fahrenheit or pressures higher than 160 psig are called ”high temperature

Deaerators in Industrial Steam Systems

Boiler Wikipedia

Steam Boiler Hot Water Boiler Industrial Autoclave

A boiler is a vessel in which water is heated under pressure and vaporized into steam for a specific purpose. There are several different kinds of boilers, heated by coal, solid fuel, oil or gas.

150 PSI High Pressure Steam Boilers Atmospheric / Natural

Thermodyne Engineering Systems — High Pressure Boiler

High pressure Boilers Boilersinfo

Comments are closed.