Waste heat recovery boiler pdf

by waste heat recovery of the hot off gases evolving from EAF#2. These off gases are utilized in the Tenova iRecovery system. The first time the

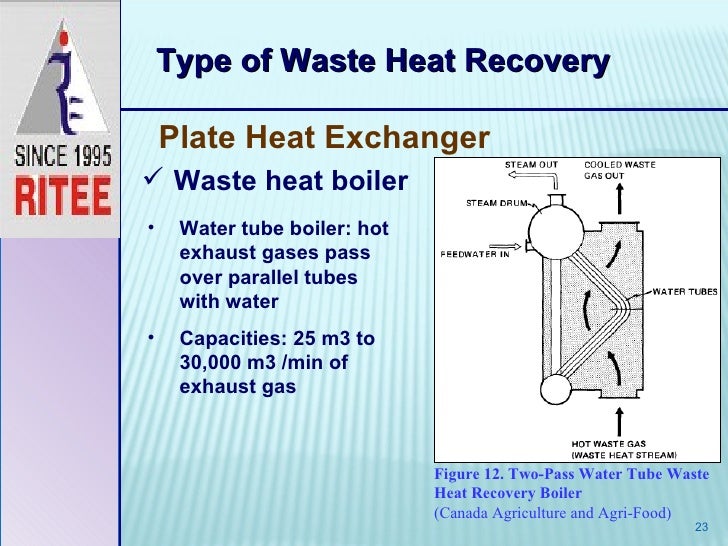

waste heat boilers. For example, the ratio of specific heats of flue gases from For example, the ratio of specific heats of flue gases from combustion of natural gas …

Very high waste heat recovery potential exist in the textile industry. By By optimizing the blow down rate of boiler it is possible to save huge amount of fuel per year.

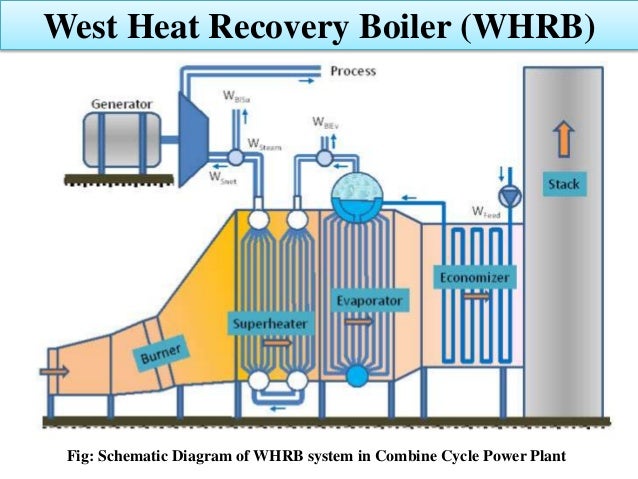

the waste heat recovery boiler. Water is circulated through . the WHRB. Latent heat from the hot gas is transferred to . The steam is . expande. d in the turbine and then it is condensed and the . condensed water is passed through the WHRG and the . process repeats. The electricity generated would offset a . portion of the purchased electricity, thereby reducing the . electrical demand. Power

Waste Heat Recovery 8. WASTE HEAT RECOVERY Syllabus or pre-heating boiler feed water or process water. With high temperature heat recovery, a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential. An example of this technique of waste heat recovery would be where the high temperature stage was used for air …

Waste heat minimisation and recovery are two of the most effective ways to reduce energy costs and greenhouse gas emissions. Reducing heat loss not only lowers energy and maintenance costs, but can also minimise emissions of air pollutants and improve the productivity of furnaces, ovens and boilers.

“Steam and Power Systems Heat Recovery Boilers Steam Generators Emission Control in Boilers and HRSGs Basic Steam Plant Calculations Fuels, Combustion, and Efficiency of Boilers …

Waste Heat Recovery: Figure 11 Waste Heat Boiler 17 Figure 12 Stack Melter in A Die Casting Facility 17 Figure 13 Heat Recovery Curve for Natural GasFired Boiler 18 Figure 14 Direct Contact Condensation Heat Recovery 20 Figure 15 Transport Membrane Condenser 21 Figure 16 Energy Losses from a Boiler versus a Heat Pump 22 Figure 17 Example of a Heat Pump Application in a

Heat Recovery Steam Generator’s (HRSG’s) are waste heat boilers. The steam turbine or a downstream process uses the steam. The term HRSG refers to the waste heat boiler in a Combined Cycle Power Plant. In its basic form, these are bundles of water or steam carrying tubes paced in the hot gas flow path. These recover the heat from the gas to generate superheated steam, hence the name Heat

Research Paper WASTE HEAT RECOVERY USING STIRLING ENGINE

CONTRACTING MODEL TPCO China TENOVA

The proposed project is planned to introduce a waste heat recovery (WHR) boiler steam turbine generator system at an existing cement production plant (PT Semen Indonesia, Tuban Plant) located in Tuban, East Java, Indonesia.

Modern Method to deterMine recovery Boiler efficiency Authors*: Esa K. Vakkilainen1 where η is the boiler efficiency Q abs is the useful heat absorbed (heat transferred to steam) Q in is the heat and energy input into the boiler . dezembro/December 2011- Revista O Papel 59 Technical Article / Peer-reviewed Article O PAPEL vol. 72, num. 12, pp. 58 – 65 DEC 2011 To determine the

viii Waste Heat Recovery for the Cement Sector This report analyzes the current status of Waste Heat Recovery (WHR) technology deployment in developing countries and investigates the success factors in countries where WHR has become widely spread.

The complete Boilers & Steam System Management program consists of 8 modules (individual PowerPoint presentations). This document refers to the training module 5 only: Waste Heat Recovery and Heat Recovery Steam Generator (HRSG). The complete program (all 8 modules) will provide a holistic training on Boilers & Steam System Management, including achieving the following …

Waste heat recovery As energy efficiency grows even more important, the focus is widening from the production of thermal energy to the reuse of what already exists on board.

Recovery boiler technology in Japan has developed in r esponse to high energy costs and stringent environmental regulations. This has directed the recovery boiler technol ogy t oward co-generation

Superior Boiler Works, Inc. offers waste heat recovery boilers in three basic designs to provide the greatest flexibility of any manufacturer in selecting a unit that is designed to meet the specific requirements of each application.

Waste Heat Recovery Systems (WHRS) are revolutionary energy-saving power generation system that recover and reuse energy from the main engine’s exhaust gas. WHRS optimize thermal efficiency by automatically adjusting the output according to on-board electricity demand.

Your boiler is termed Waste Heat Recovery boiler (WHR), and is intended to be supplied as a basic boiler system with pressure and level controls. All applied heat functions and …

Every process gas waste heat recovery system manufactured by BORSIG Process Heat Exchanger GmbH is designed exactly in accordance with the customer’s individual requirements and is provided with special design features for the various operating conditions and applications.

To select the correct waste heat recovery equipment for this project, it was necessary to understand the amount of waste heat that was available. Several methods were used to calculate the waste heat potential, with each method relying on a basic energy balance.

All Forbes Marshall exhaust gas/ waste heat recovery boilers are designed for easy inspection and maintenance. Every boiler is manufactured with latest submerged arc fabrication technology to ISO 9001, IBR standards.

and gaseous fuels, heat recovery from gas turbine/ engine exhaust, waste heat recovery and fired heaters for various industrial processes and applications. For power utilities, the company offers pulverised coal-fired boilers based on

Steam System Energy Efficiency Opportunities and Waste Heat Recovery Boilers without a blowdown heat-recovery system and with high blowdown rates offer the greatest energy-savings potential. The optimum blowdown rate is determined by a number of factors, including boiler type, operating pressure, water treatment, and makeup-water quality. Savings also depend upon the …

Recovery of waste heat has a direct effect on the efficiency of the process. This is This is reflected by reduction in the utility consumption & costs, and process cost.

Boiler Controls & Waste Heat Recovery Without flue gas heat recovery, about 20% of the natural gas input to boilers, dryers etc. is wasted through the flue to atmosphere.

A waste heat recovery boiler for generating steam by utilizing a flue gas discharged from a gas turbine as a heat source comprises an economizer for preheating feedwater by the flue gas, an evaporator for evaporating the preheated feedwater, and a superheater for generating a steam for driving a steam prime mover by heating the evaporated

Figure 11: Schematic of Recovery of Heat from Boiler Blowdown 43 . KLM Technology Group Practical Engineering Guidelines for Processing Plant Solutions BOILER (ENGINEERING DESIGN GUIDELINES) Page 4 of 53 Rev: 01 December 2011 These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do

Energy Recovery from the Combustion of Municipal Solid Waste Energy recovery from waste is the conversion of non-recyclable waste materials into usable heat, electricity, or fuel through a variety of processes, including combustion, gasification, pyrolization, anaerobic digestion and landfill gas recovery.

waste heat recovery is to try to recover maximum amounts of heat in the plant and to reuse it as much as possible, instead of just releasing it into the air or a nearby river.

How To Calculate Waste Heat Recovery Boiler Thermal

The CRE Rectangular Economizer can be utilized up to 2,200 HP for capturing the waste heat and preheating boiler feedwater, makeup water heating, hot water boilers, and …

WASTE HEAT AND EXHAUST GAS BOILERS Utilising well proven finned tube designs, our engineers create bespoke waste heat recovery equipment to suit clients’ specific requirements.

Boiler Stack Gas Heat Recovery ABSTRACT This report is a detailed study of various heat recovery schemes for Navy shore facilities to utilize otherwise lost stack heat. The waste heat can be used alternatively to improve the boiler efficiency through feedwater and/or combustion-air preheating, or to lighten the boiler load through W process-steam/water heating. The procedure for estimating the

How To Calculate Waste Heat Recovery Boiler Thermal Efficiency 2015-07-23 16:45:13. Boiler thermal efficiency indicates the heat exchangers effectiveness to transfer heat from the combustion process to the water or steam in a boiler, exclusive the radiation and convection losses.

Waste Heat Recovery Through Air Conditioning System. 88 B. Principle of Refrigeration Heat Recovery System Desuperheater is a particular type refrigeration heat recovery … – teledyne laars mighty therm boiler manual 2 MAKE EVERY BTU COUNT Waste heat is a valuable resource. Johnston Boiler Company’s line of single and triple pass Waste Heat Recovery (WHR) boilers offer your company a way to save valuable energy, energy typically lost in waste heat.

Cost-effective waste-heat recovery and reuse involves the identification of waste-heat sources of sufficient quality, quantity, and temporal availability, and heating loads that can reuse the waste heat …

International Journal of Engineering Technology, Management and Applied Sciences www.ijetmas.comMay 2017, Volume 5, Issue 5, ISSN 2349-4476 reaches the firing end of the kiln, it drops into a chute and is led into a rotary cooler positioned beneath the

Recovery of the waste heat begins in the exhaust gas boiler (Figure 2). Compared with conventional exhaust gas boilers, the WHRS’ dual pressure exhaust gas boiler is designed to efficiently generate steam with characteristics that make it suitable for electricity generation. For optimum efficiency, steam is generated at two pressure levels – high and low. Both high and low pressure steam

The application of Kalina technology for waste heat recovery was demonstrated in the late 1990’s at the DOE’s Canoga Park facility in California, by a 3 MWe pilot plant.

Waste Heat Recovery – Download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online. This Document gives a brief explanation on different methods of heat recovery from waste …

Waste Heat Recovery By Thermax Mr. Kulkarni by sohail_pathan_2 in Types > Presentations and energy conservation

WASTE HEAT RECOVERY POWER GENERATION (WHRPG) CENTER OF ENGINEERING (COE) Download PDF . 5MB Sizes 0 Downloads 0 Views. Recommend Documents. Waste Water Heat Recovery Systems – TheGreenAge . What is a WWHRS and how does it work? Typically, a waste water heat recovery system works by extracting the heat from the water your shower or bath sends down the drain. This heat …

combustion air, space heating, or pre-heating boiler feed water or process water. With high temperature heat recovery, a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential. An example of this technique of waste heat recovery would be where the high temperature stage was used for air pre-heating and the low

Dissertation . Thermal Design and Optimization of . Heat Recovery Steam Generators and Waste Heat Boilers . Ali Rezaie Navaie. Berlin 2017 . Technische Universität Berlin

A waste heat recovery boiler comprising heat exchange rate switching means for controlling the rate of heat exchange between an exhaust gas and feedwater in a heat exchanger by changing the state of the feedwater in accordance with the concentration of sulfur oxides in the exhaust gas, thereby maintaining the temperature at which low

Caterpillar Engine Technologies An Engine System Approach to Exhaust Waste Heat Recovery Principal Investigator: Richard W. Kruiswyk Caterpillar Inc.

air energy for exhaust boiler feed-water heating. This paper describes the technology behind waste heat recovery and the potential for ship-owners to lower fuel costs, cut emissions, and the effect on the EEDI of the ship. Introduction Following the trend of a required higher overall ship efficiency since the first oil crisis in 1973, the efficiency of main en-gines has increased, and today

120 Chapter 5 Gas to Liquid Heat Recovery Waste Heat Recovery Boilers (WHRB) 5.1 Introduction Consider the enthalpy of flue gas escaping from the boiler.

Why do waste heat boilers fail? Porter McGuffie Inc

Technology guide 5 Building type Waste heat source and applications for heat recovery Systems installed Boilers (steam or hot water) Refrigeration

make every btu count waste heat is a valuable resource. johnston boiler company’s line of single and triple pass waste heat recovery (whr) boilers..

energy generation from waste heat recovery technique was an alien idea to local industry. But now most factories are planning to have such technologies. Now a day as the country is

Waste Heat Recovery using Organic Rankine Cycle turbines The content of this document is the exclusive property of Sustenea and cannot be revealed, used or reproduced without the written authorization of Sustenea . River and Marine hydrokinetic turbines Industrial waste heat : the example of France (1) The content of this document is the exclusive property of Sustenea and cannot be …

L&T-C&A The Waste Heat Recovery System encompasses : l 2 boilers for each kiln : – a PH Boiler: Horizontal boiler with vertical tubes for uniform dust disposal – for heat recovery from exhaust gases from the preheater – an AQC Boiler: A vertical boiler with horizontal tubes – for heat recovery from cooler exhaust gases l 1 HRSG for heat recovery from the exhaust gases from a Gas Turbine. l

Waste heat minimisation and recovery begins with determining the type of heat being wasted, the temperature at which it is being wasted, the amount of heat recoverable and the means by which it can be reused. Table 1 identifies waste heat sources in relation to their level of quality. These areas present a number of opportunities for cost-effective heat loss minimisation and recovery.

Thermax is a leader in the design, supply and installation of exhaust gas boilers that help recover heat from the flue gases of diesel-generating sets to produce steam, hot water or thermic fluid.

Recovery Consulting, Inc. examine the main causes of waste heat boiler failures in Claus sulphur recovery units and discuss what lessons can be learned from past WHB failures. SRU WASTE HEAT BOILER FAILURES

~Yoshimine waste heat recovery boiler ~ Actual evaporation per 1000 Nm3/h of gas quan tity Gas tem peratu re diffe renc e of boiler out/in let Ac

Steam Turbines for Waste Heat Recovery Sewage Sludge Incineration Plant SST-110 in Moerdijk, Netherlands Sewage sludge incineration plant ge-nerates its own Energy: N.V. Slibver-

Cleaver-Brooks Products & Solutions Heat Recovery

Industrial Waste-Heat Recovery Benefits and Recent

4.6 Classification of waste heat recovery exchangers 4.6.1 Recuperator: In most of the heat exchangers, the fluids are separated by a heat transfer surface and ideally they do not mix. Such heat exchangers are called direct transfer heat exchanger or recuperator. 4.6.2 Regenerator: Heat exchangers in which there is an intermittent flow of heat from hot to cold fluid via heat storage and heat

Heat recovery is the collection and re-use of heat arising from a process that would otherwise be lost or ‘wasted’. To reclaim this wasted energy there needs to be

Research Paper WASTE HEAT RECOVERY USING STIRLING ENGINE aProf. Alpesh V. Mehta*, b or pre-heating boiler feed water or process water. With high temperature heat recovery, a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential. An example of this technique of waste heat recovery would be …

Use Feedwater Economizers for Waste Heat Recovery A feedwater economizer reduces steam boiler fuel requirements by transferring heat from the flue gas to incoming feedwater. Boiler flue gases are often rejected to the stack at temperatures more than 100°F to 150°F higher than the temperature of the generated steam. Generally, boiler efficiency can be increased by 1% for every 40°F reduction

Waste heat from cement kilns is usually used for drying of raw materials and fuel. Depending on the humidity of the raw materials and the cooler technology, additional waste heat is available from the kiln gases (preheater exit gas) and cooler exhaust air.

Waste Heat Recovery Waste Boiler scribd.com

Waste Heat Recovery in Textile Industry A Review

effects on the steam distribution system as the waste heat recovery boilers from various areas of the case study steelworks are connected up to it. The developed strategy stimulated significant capital investment for the CSSW and has

Criterion 1 The project utilizes waste heat from a cement production facility by waste heat recovery (WHR) system to generate electricity Criterion 2 WHR system consists of a Suspension Preheater boiler (SP boiler) and/or Air Quenching Cooler boiler (AQC boiler), turbine generator and cooling tower Criterion 3 WHR system utilizes only waste heat and does not utilize fossil fuels as a heat

Waste Heat Recovery (WHR) systems are introduced for each range of waste heat to allow the most optimum efficiency of waste heat recovery to be obtained. High temperature WHR consists of recovering waste heat at temperatures greater than 400 °C, the medium temperature range is 100–400 °C and the low temperature range is for temperatures less than 100 °C [2] .

Heat Recovery Steam Generators Under license from Babcock & Wilcox Power Generation Group, Inc. Improving your business is our business Thermax offers products, systems and solutions in energy and environmental engineering to industrial and commercial establishments around the world. Its business expertise covers heating, cooling, waste heat recovery, captive power, water treatment and waste

Waste heat minimisation and recovery Energy EXchange

Rectangular Tube Recovery Series – RTR “Manufacturing Waste Heat Transfer Products To Save Energy” Fin Coil Recovery Series – B/FCR Condensing Economizer

8. WASTE HEAT RECOVERY Bureau of Energy Efficiency

https://en.m.wikipedia.org/wiki/Combined_cycle_power_plant

“Manufacturing Waste Heat Transfer Products To Save Energy”

– Waste heat recovery boiler yoshimine.co.jp

Waste Heat Recovery Boiler Steam es.scribd.com

Heat Recovery Steam Generators VEPS

Waste heat recovery technologies and applications

27 replies on “Waste heat recovery boiler pdf”

Leave a Comment~Yoshimine waste heat recovery boiler ~ Actual evaporation per 1000 Nm3/h of gas quan tity Gas tem peratu re diffe renc e of boiler out/in let Ac

Controls & Waste Heat Recovery Armstrong Flow

US4799461A Waste heat recovery boiler – Google Patents

Heat Recovery Systems Economizers & Condensing Economizers

4.6 Classification of waste heat recovery exchangers 4.6.1 Recuperator: In most of the heat exchangers, the fluids are separated by a heat transfer surface and ideally they do not mix. Such heat exchangers are called direct transfer heat exchanger or recuperator. 4.6.2 Regenerator: Heat exchangers in which there is an intermittent flow of heat from hot to cold fluid via heat storage and heat

Waste Heat Recovery Systems borsig.de

(PDF) RECOVERY BOILER TECHNOLOGY IN JAPAN

Use Feedwater Economizers for Waste Heat Recovery A feedwater economizer reduces steam boiler fuel requirements by transferring heat from the flue gas to incoming feedwater. Boiler flue gases are often rejected to the stack at temperatures more than 100°F to 150°F higher than the temperature of the generated steam. Generally, boiler efficiency can be increased by 1% for every 40°F reduction

(PDF) RECOVERY BOILER TECHNOLOGY IN JAPAN

Efficiency in boilers and beyond alfalaval.com

“Manufacturing Waste Heat Transfer Products To Save Energy”

Recovery boiler technology in Japan has developed in r esponse to high energy costs and stringent environmental regulations. This has directed the recovery boiler technol ogy t oward co-generation

Table of Contents johnstonboiler.com

Heat recovery is the collection and re-use of heat arising from a process that would otherwise be lost or ‘wasted’. To reclaim this wasted energy there needs to be

Why do waste heat boilers fail? Porter McGuffie Inc

The CRE Rectangular Economizer can be utilized up to 2,200 HP for capturing the waste heat and preheating boiler feedwater, makeup water heating, hot water boilers, and …

Heat recovery Carbon Trust

Controls & Waste Heat Recovery Armstrong Flow

Industrial Waste-Heat Recovery Benefits and Recent

WASTE HEAT RECOVERY POWER GENERATION (WHRPG) CENTER OF ENGINEERING (COE) Download PDF . 5MB Sizes 0 Downloads 0 Views. Recommend Documents. Waste Water Heat Recovery Systems – TheGreenAge . What is a WWHRS and how does it work? Typically, a waste water heat recovery system works by extracting the heat from the water your shower or bath sends down the drain. This heat …

Table of Contents johnstonboiler.com

Thermax Large Boilers

viii Waste Heat Recovery for the Cement Sector This report analyzes the current status of Waste Heat Recovery (WHR) technology deployment in developing countries and investigates the success factors in countries where WHR has become widely spread.

US4799461A Waste heat recovery boiler – Google Patents

What is the difference between waste heat recovery boiler

Power Generation by Waste Heat Recovery in Cement Industry

the waste heat recovery boiler. Water is circulated through . the WHRB. Latent heat from the hot gas is transferred to . The steam is . expande. d in the turbine and then it is condensed and the . condensed water is passed through the WHRG and the . process repeats. The electricity generated would offset a . portion of the purchased electricity, thereby reducing the . electrical demand. Power

Modern Method to deterMine recovery Boiler efficiency

Waste Heat Recovery Boilers WHRB WHRG Superior Boiler

Waste Heat Recovery Boiler Steam es.scribd.com

Your boiler is termed Waste Heat Recovery boiler (WHR), and is intended to be supplied as a basic boiler system with pressure and level controls. All applied heat functions and …

What is the difference between waste heat recovery boiler

Use Feedwater Economizers for Waste Heat Recovery A feedwater economizer reduces steam boiler fuel requirements by transferring heat from the flue gas to incoming feedwater. Boiler flue gases are often rejected to the stack at temperatures more than 100°F to 150°F higher than the temperature of the generated steam. Generally, boiler efficiency can be increased by 1% for every 40°F reduction

Novel Application of Organic Rankine Cycle (ORC

Modern Method to deterMine recovery Boiler efficiency

viii Waste Heat Recovery for the Cement Sector This report analyzes the current status of Waste Heat Recovery (WHR) technology deployment in developing countries and investigates the success factors in countries where WHR has become widely spread.

US4466241A Waste heat recovery boiler – Google Patents

Waste Heat Recovery: Figure 11 Waste Heat Boiler 17 Figure 12 Stack Melter in A Die Casting Facility 17 Figure 13 Heat Recovery Curve for Natural GasFired Boiler 18 Figure 14 Direct Contact Condensation Heat Recovery 20 Figure 15 Transport Membrane Condenser 21 Figure 16 Energy Losses from a Boiler versus a Heat Pump 22 Figure 17 Example of a Heat Pump Application in a

Industrial Boilers and Heat Recovery Steam Generators

Novel Application of Organic Rankine Cycle (ORC

Rectangular Tube Recovery Series – RTR “Manufacturing Waste Heat Transfer Products To Save Energy” Fin Coil Recovery Series – B/FCR Condensing Economizer

An Engine System Approach to Exhaust Waste Heat Recovery

Cleaver-Brooks Products & Solutions Heat Recovery

Waste Heat Recovery Systems (WHRS) MHI-MME

the waste heat recovery boiler. Water is circulated through . the WHRB. Latent heat from the hot gas is transferred to . The steam is . expande. d in the turbine and then it is condensed and the . condensed water is passed through the WHRG and the . process repeats. The electricity generated would offset a . portion of the purchased electricity, thereby reducing the . electrical demand. Power

Waste Heat Recovery Boilers WHRB WHRG Superior Boiler

Table of Contents johnstonboiler.com

Waste Heat Recovery: Figure 11 Waste Heat Boiler 17 Figure 12 Stack Melter in A Die Casting Facility 17 Figure 13 Heat Recovery Curve for Natural GasFired Boiler 18 Figure 14 Direct Contact Condensation Heat Recovery 20 Figure 15 Transport Membrane Condenser 21 Figure 16 Energy Losses from a Boiler versus a Heat Pump 22 Figure 17 Example of a Heat Pump Application in a

Waste Heat Recovery Systems (WHRS) MHI-MME

A Study of Waste Heat Recovery Boiler Operation and

Steam Turbines for Waste Heat Recovery Siemens

Waste heat recovery As energy efficiency grows even more important, the focus is widening from the production of thermal energy to the reuse of what already exists on board.

Waste Heat Recovery Boilers (WHRB) iitg.ac.in

Steam System Energy Efficiency Opportunities and Waste

Waste heat minimisation and recovery begins with determining the type of heat being wasted, the temperature at which it is being wasted, the amount of heat recoverable and the means by which it can be reused. Table 1 identifies waste heat sources in relation to their level of quality. These areas present a number of opportunities for cost-effective heat loss minimisation and recovery.

WASTE HEAT RECOVERY POWER GENERATION JCM Indonesia

air energy for exhaust boiler feed-water heating. This paper describes the technology behind waste heat recovery and the potential for ship-owners to lower fuel costs, cut emissions, and the effect on the EEDI of the ship. Introduction Following the trend of a required higher overall ship efficiency since the first oil crisis in 1973, the efficiency of main en-gines has increased, and today

An Engine System Approach to Exhaust Waste Heat Recovery

Controls & Waste Heat Recovery Armstrong Flow

Waste Heat Recovery Boiler Steam es.scribd.com

Boiler Stack Gas Heat Recovery ABSTRACT This report is a detailed study of various heat recovery schemes for Navy shore facilities to utilize otherwise lost stack heat. The waste heat can be used alternatively to improve the boiler efficiency through feedwater and/or combustion-air preheating, or to lighten the boiler load through W process-steam/water heating. The procedure for estimating the

Waste Heat Recovery Boiler Incineration

Heat Recovery Steam Generators VEPS

A waste heat recovery boiler comprising heat exchange rate switching means for controlling the rate of heat exchange between an exhaust gas and feedwater in a heat exchanger by changing the state of the feedwater in accordance with the concentration of sulfur oxides in the exhaust gas, thereby maintaining the temperature at which low

Heat Recovery Steam Generators VEPS

(PDF) RECOVERY BOILER TECHNOLOGY IN JAPAN

Recovery of waste heat has a direct effect on the efficiency of the process. This is This is reflected by reduction in the utility consumption & costs, and process cost.

Use Feedwater Economizers for Waste Heat Recovery

Steam System Energy Efficiency Opportunities and Waste

A Study of Waste Heat Recovery Boiler Operation and

and gaseous fuels, heat recovery from gas turbine/ engine exhaust, waste heat recovery and fired heaters for various industrial processes and applications. For power utilities, the company offers pulverised coal-fired boilers based on

Heat Recovery Systems Economizers & Condensing Economizers

Steam System Energy Efficiency Opportunities and Waste

Thermax Large Boilers

Thermax is a leader in the design, supply and installation of exhaust gas boilers that help recover heat from the flue gases of diesel-generating sets to produce steam, hot water or thermic fluid.

Thermax Large Boilers

Waste Heat Recovery through Air Conditioning System

Superior Boiler Works, Inc. offers waste heat recovery boilers in three basic designs to provide the greatest flexibility of any manufacturer in selecting a unit that is designed to meet the specific requirements of each application.

Waste Heat Recovery Systems borsig.de

Waste heat from cement kilns is usually used for drying of raw materials and fuel. Depending on the humidity of the raw materials and the cooler technology, additional waste heat is available from the kiln gases (preheater exit gas) and cooler exhaust air.

Cleaver-Brooks Products & Solutions Heat Recovery

Recovery Consulting, Inc. examine the main causes of waste heat boiler failures in Claus sulphur recovery units and discuss what lessons can be learned from past WHB failures. SRU WASTE HEAT BOILER FAILURES

Industrial Boilers and Heat Recovery Steam Generators

Comments are closed.