Water tube boiler maintenance pdf

THE PARKER BOILER DESIGN The Parker Boiler water tube design offers an extremely effi-cient, reliable steam boiler built for the long term and ease of maintenance. The Parker Boiler design offers many advantages. Compare ours to the competition. ADVANTAGES 1. Safety The Parker Boiler tube bundle is extremely flexible and offers a long life with a 25 year warranty against thermal shock. No

Why Water Tube Boilers ? In contrast to its internal construction, which includes a small steam drum and small diameter tubes, the water tube boiler is used to …

1 Boiler Tube Failure, Prevention and Control Mike Rogers Alberta Technology & Science Inc October 12, 2006 2 Introduction • The content of this short presentation is

Boiler Maintenance Checklist A Scotch-marine steam boiler, common in residential buildings, typically lasts 25 to 30 years with proper maintenance. Following a regular maintenance schedule for your building’s boiler plant will go a long way toward minimizing breakdowns and service interruptions.

A boiler is an enclosed vessel in which water is heated and circulated, either as hot water or steam, to produce a source for either heat or power.

3/10/2013 · Many equipment breakdown losses can be traced to improper maintenance of boilers and pressure vessels. In this video we’ll discuss how to maintain and operate a boiler …

Watertube boilers of the bent tube design are capable of greater steam capacities, higher pressures, and greater versatility in arrangements such as floor space, head …

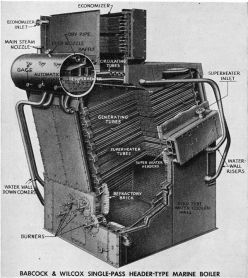

Composite Marine Boilers from SAACKE

Advanced Boilers & Combustion Watertube boiler Steam

Warranty Registration Card must be filled out by the customer and mailed within thirty (30) days of installa-tion in order to gain warranty coverage.

Selection of a boiler with “designedin” low maintenance costs – and excellent fuel-to-steam or fuel-to-water efficiency will provide substantial savings and maximize your boiler investment.

Series 3 – Packaged Firetube Boiler Save Thousands Of Dollars Over The Life Of Your Boiler Long-term energy and maintenance efficiencies are the

4 C. Boiler Water Level: On every steam boiler there is a small glass tube located on the outside of the boiler. Commonly called a “Gauge Glass”, this tube

View and Download UTICA BOILERS STARFIRE 3 WATER installation, operation & maintenance manual online. OIL FIRED CAST IRON BOILER. STARFIRE 3 WATER Boiler pdf manual download. OIL FIRED CAST IRON BOILER.

Increased downtime and maintenance costs; Tube overheating and limited boiler capacity. In addition, there is the potential for excessive water deposition due to low flow, feed-water control

18/09/2014 · Boiler expert Tim McDaniel guides you through the basics of boiler operation safety. You will learn basic boiler systems and classifications, operator responsibilities and preventative maintenance

Tube that boiler water flows in inside and is in contact with combustion gas. System heating the supplied water to reduce O ¸ melted in the water. The condition that P/P is not operated normally with influx of air into P/P.

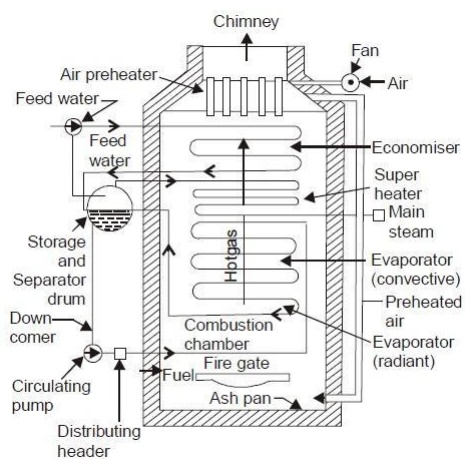

DIESEL AND BLAST FURNACE GAS FIRED BOILER OPERATION AND MAINTENANCE The working principle of water tube boiler is very interesting and simple. It consists of mainly two drums, one is upper drum called steam drum other is lower drum called mud drum. These upper drum and lower drum are connected with two tubes namely down-comer and riser tubes as shown in the picture. Water …

maintenance, and upgrading boilers and distribution systems. It also introduces some simple measures regarding distribution systems associated with steam and high temperature boilers. MENU. Steam and high temperature hot water boilers 6 Technology overview Boilers A boiler is a device that converts the chemical energy of a fuel into a useful heat output, such as steam or hot water. The fuel

by: Mohammad A. Malek, Ph.D., P.E. Abstract: Both a valuable on-the-job tool and a licensing exam study guide, the Heating Boiler Operator’s Manual offers boiler professionals a clear, straightforward account of cutting-edge methods for the operation, maintenance, and repair of today’s heating boilers.

View and Download Lochinvar Electric Hot Water and Steam Boilers operation and maintenance manual online. Electric Hot Water and Steam Boilers. Electric Hot Water and Steam Boilers Boiler pdf manual download.

Clean heat transfer surfaces o Clean slag off tube exterior o Flush boiler with water to remove loose internal scale and sediment. o Prevent scale formation.

(o) High temperature water boiler means a boiler completely filled with water intended for operation at pressures in excess of 160 psi or temperatures in excess of 250° Fahrenheit. (p) Hot water heating boiler means a boiler in which no steam is generated, from which hot water is circulated for

RULES AND REGULATIONS FOR BOILER AND PRESSURE VESSEL INSPECTION (R.I.G.L. – 28-25) Revised July 2011 RI Department of Labor & Training Division of Occupational Safety

waste liquid improves efficiency greatly and easy maintenance and operation. Multi boiler water level control devices ensure safety operation for the boilers. Start-up time is short.

example of thermodynamic calculation of d-type water tube boiler with superheater and economizer using boiler design software. 1 example of thermodynamic calculation of d-type water tube boiler with superheater and economizer using boiler design software 2 .

Fire Tube Boiler Water Tube Boiler The hot gases from the furnace pass through the tubes which are surrounded by water in the shell The water circulates inside the tubes which are surrounded by hot gases from the furnace It cannot handle high pressure It is a high pressure boiler The rate of generation of steam is relatively low The rate of generation of steam is high Overall efficiency is up

Our Water Tube Boiler Repair Service is fast and cost effective. We respond at the first instance to get you back up and running. There are many types of water tube boilers, we specialise in repairing all common water tube boilers, including D type boilers.

Superheater tubes These are small diameter tubes in the gas flow after the screen tubes. more commonly found in boilers of an older design For roof fired boilers the generating bank may consist of one or two rows of close pitched tubes. For a set water circulation the tube diameter is limited to a minimum as the ratio of steam to water can increase to a point where the possibility of

boiler room log (maintenance check list) month _____ year _____ pressure and temp. gages check water level check lube oil in oil pump check oil in compressor check status of automatic chemical feeder system pressor air filter initials blow down low water cut off clean smoke alarm lens clean oil strainers flush water column keep boiler room clean and tidy initials check tubes and breeching

Precautions for Cleaning Water-tube Boilers NOTE: welding or cutting for tube repair or replacement is to be done. If any cutting of welding is done inside the fireboxes a permit would certainly be required.” Permits for entry in confined spaces should include: (1) the hazards of the permit space (2) specific measures to be taken to ensure isolation of the space (3) lockout/tagout

Water Tube Boiler the Parat water tube boiler is a fully automatic steam boiler. a well dimensioned steam drum make the boiler suitable for evaporating steam from other exhaust gas boilers.the design and performance is a result of solid experience and high

Typically, boilers are opened for routine maintenance and inspection annually. Not only will the regulatory/insurance inspectors be looking at the boilers on a routine basis, but plant operators and the water management consultant should inspect the boiler every chance they get. The water management consultant will be inspecting both the water and firesides to evaluate the overall

maintenance. This unique boiler feature locates total water cooling where it can contribute most to keeping mainte – nance costs down. Each rear wall tube is a single flow path between drums to assure proper circulation and cooling. 2) Gas-tight setting membrane provides the gas-tight setting absolutely necessary on all package boilers. This construction uniquely inhibits dew-point sulfur

− Remember process boilers require reliable operating controls, a water treatment program and knowledgeable operators. − Your process boiler is a very important part of your production process.

Boiler repair We support you over the whole life-cycle of the boiler plant – worldwide. Our manufacturer-independent range of services covers not only the classic boiler repair by certified and qualified personnel, but also the project-specific manufacture of complete new boiler pressure chambers, if necessary also made-to-measure from existing drawings.

Water Tube Boilers output range from small capacity up to large capacity of saturated up to superheated steam. 2MW 12 bar steam boiler. The Maxitherm Water Tube Boilers can use any type of fuel (Oil, Gas, Wood, Agricultural Waste, Coal, etc).

Heat Transfer Water Tube Boiler Scribd

Water tube Boiler Commissioning Procedure and Checklists September 7, 2017 Boiler articles , Boiler Commissioning , Power plant Articles , Water tube Boilers Leave a comment 11,270 Views The operation of checking the equipment and tuning them before putting into commercial operation is commonly termed as ‘commissioning’.

of maintenance, operation hours, feed water treatment and sizing of boilers on its performance. Maintenance of boilers includes cleaning and replacing metal parts in the boiler such as water tubes, regular inspection of metals for deterioration and routine tune up of the boilers.

The CMB-VS is a combined vertical exhaust gas and oil fired boiler. The heat transfer in the standard oil fired section is performed through the plate furnace and a number of rifled plain smoke tubes. – low pressure boilers 4th edition pdf The configuration of the water tubes pr ovides a water cooled combustion chamber. A high percentage of the heating A high percentage of the heating surface is exposed to direct radiant heat, in creasing water velocities and heat transfer.

Water Tube Boiler Furnace Boiler Scribd

PART 14 CONSTRUCTION INSTALLATION INSPECTION AND

Boiler Tube Failure Prevention and Control NACE Edmonton

RULES AND REGULATIONS FOR BOILER AND PRESSURE VESSEL

Boiler Maintenance & Efficiency YouTube

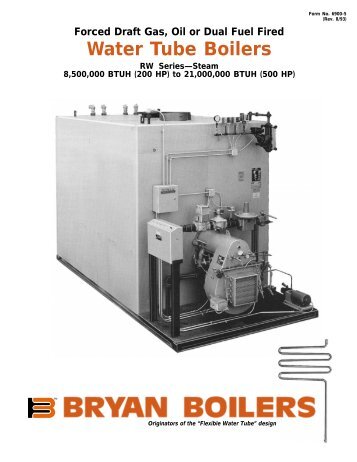

BRYAN “FLEXIBLE WATER TUBE” RW SERIES STEAM AND WATER BOILER

Boiler repair saacke.com

Determining & Testing Boiler Efficiency for Commercial

– Maintenance and Water Treatment for Your Process Boiler

Boiler and Chiller Maintenance for Maximum Efficiency

Boiler Operation Safety Boiler Maintenance Practice

Horizontal Drum Sectional Water Tube Parker Boiler

BRYAN “FLEXIBLE WATER TUBE” RW SERIES STEAM AND WATER BOILER

Boiler Maintenance RAND Engineering & Architecture DPC

Superheater tubes These are small diameter tubes in the gas flow after the screen tubes. more commonly found in boilers of an older design For roof fired boilers the generating bank may consist of one or two rows of close pitched tubes. For a set water circulation the tube diameter is limited to a minimum as the ratio of steam to water can increase to a point where the possibility of

of maintenance, operation hours, feed water treatment and sizing of boilers on its performance. Maintenance of boilers includes cleaning and replacing metal parts in the boiler such as water tubes, regular inspection of metals for deterioration and routine tune up of the boilers.

THE PARKER BOILER DESIGN The Parker Boiler water tube design offers an extremely effi-cient, reliable steam boiler built for the long term and ease of maintenance. The Parker Boiler design offers many advantages. Compare ours to the competition. ADVANTAGES 1. Safety The Parker Boiler tube bundle is extremely flexible and offers a long life with a 25 year warranty against thermal shock. No

Water tube Boiler Commissioning Procedure and Checklists September 7, 2017 Boiler articles , Boiler Commissioning , Power plant Articles , Water tube Boilers Leave a comment 11,270 Views The operation of checking the equipment and tuning them before putting into commercial operation is commonly termed as ‘commissioning’.

− Remember process boilers require reliable operating controls, a water treatment program and knowledgeable operators. − Your process boiler is a very important part of your production process.

3/10/2013 · Many equipment breakdown losses can be traced to improper maintenance of boilers and pressure vessels. In this video we’ll discuss how to maintain and operate a boiler …

by: Mohammad A. Malek, Ph.D., P.E. Abstract: Both a valuable on-the-job tool and a licensing exam study guide, the Heating Boiler Operator’s Manual offers boiler professionals a clear, straightforward account of cutting-edge methods for the operation, maintenance, and repair of today’s heating boilers.

boiler room log (maintenance check list) month _____ year _____ pressure and temp. gages check water level check lube oil in oil pump check oil in compressor check status of automatic chemical feeder system pressor air filter initials blow down low water cut off clean smoke alarm lens clean oil strainers flush water column keep boiler room clean and tidy initials check tubes and breeching

Increased downtime and maintenance costs; Tube overheating and limited boiler capacity. In addition, there is the potential for excessive water deposition due to low flow, feed-water control

Boiler Maintenance Checklist A Scotch-marine steam boiler, common in residential buildings, typically lasts 25 to 30 years with proper maintenance. Following a regular maintenance schedule for your building’s boiler plant will go a long way toward minimizing breakdowns and service interruptions.

Fire Tube Boiler Water Tube Boiler The hot gases from the furnace pass through the tubes which are surrounded by water in the shell The water circulates inside the tubes which are surrounded by hot gases from the furnace It cannot handle high pressure It is a high pressure boiler The rate of generation of steam is relatively low The rate of generation of steam is high Overall efficiency is up

Watertube boilers of the bent tube design are capable of greater steam capacities, higher pressures, and greater versatility in arrangements such as floor space, head …

Water Tube Boilers output range from small capacity up to large capacity of saturated up to superheated steam. 2MW 12 bar steam boiler. The Maxitherm Water Tube Boilers can use any type of fuel (Oil, Gas, Wood, Agricultural Waste, Coal, etc).

26 replies on “Water tube boiler maintenance pdf”

Leave a CommentSelection of a boiler with “designedin” low maintenance costs – and excellent fuel-to-steam or fuel-to-water efficiency will provide substantial savings and maximize your boiler investment.

Boiler Maintenance & Efficiency YouTube

Determining & Testing Boiler Efficiency for Commercial

Lochinvar Electric Hot Water and Steam Boilers Operation

Typically, boilers are opened for routine maintenance and inspection annually. Not only will the regulatory/insurance inspectors be looking at the boilers on a routine basis, but plant operators and the water management consultant should inspect the boiler every chance they get. The water management consultant will be inspecting both the water and firesides to evaluate the overall

Composite Marine Boilers from SAACKE

Maintenance and Water Treatment for Your Process Boiler

Combination Boiler /or Water Heater Triangle Tube

Boiler Maintenance Checklist A Scotch-marine steam boiler, common in residential buildings, typically lasts 25 to 30 years with proper maintenance. Following a regular maintenance schedule for your building’s boiler plant will go a long way toward minimizing breakdowns and service interruptions.

Boiler repair saacke.com

Boiler Operation Safety Boiler Maintenance Practice

Boiler Repair Service Water tube boilers

18/09/2014 · Boiler expert Tim McDaniel guides you through the basics of boiler operation safety. You will learn basic boiler systems and classifications, operator responsibilities and preventative maintenance

Boiler Maintenance and Upgrades — Attacking Tube Failures

Warranty Registration Card must be filled out by the customer and mailed within thirty (30) days of installa-tion in order to gain warranty coverage.

Water Tube Boiler Furnace Boiler Scribd

RULES AND REGULATIONS FOR BOILER AND PRESSURE VESSEL

Boiler repair saacke.com

waste liquid improves efficiency greatly and easy maintenance and operation. Multi boiler water level control devices ensure safety operation for the boilers. Start-up time is short.

Horizontal Drum Sectional Water Tube Parker Boiler

Boiler repair saacke.com

UTICA BOILERS STARFIRE 3 WATER Installation Operation

Tube that boiler water flows in inside and is in contact with combustion gas. System heating the supplied water to reduce O ¸ melted in the water. The condition that P/P is not operated normally with influx of air into P/P.

BRYAN “FLEXIBLE WATER TUBE” RW SERIES STEAM AND WATER BOILER

Why Water Tube Boilers ? In contrast to its internal construction, which includes a small steam drum and small diameter tubes, the water tube boiler is used to …

PART 14 CONSTRUCTION INSTALLATION INSPECTION AND

MANUAL miuraboiler.kr

Boiler repair We support you over the whole life-cycle of the boiler plant – worldwide. Our manufacturer-independent range of services covers not only the classic boiler repair by certified and qualified personnel, but also the project-specific manufacture of complete new boiler pressure chambers, if necessary also made-to-measure from existing drawings.

Marine Boilers ShipServ

18/09/2014 · Boiler expert Tim McDaniel guides you through the basics of boiler operation safety. You will learn basic boiler systems and classifications, operator responsibilities and preventative maintenance

Marine Boilers ShipServ

UTICA BOILERS STARFIRE 3 WATER Installation Operation

Boiler Maintenance & Efficiency YouTube

RULES AND REGULATIONS FOR BOILER AND PRESSURE VESSEL INSPECTION (R.I.G.L. – 28-25) Revised July 2011 RI Department of Labor & Training Division of Occupational Safety

Lochinvar Electric Hot Water and Steam Boilers Operation

Why Water Tube Boilers ? In contrast to its internal construction, which includes a small steam drum and small diameter tubes, the water tube boiler is used to …

Boiler Room Log 5-06

MANUAL miuraboiler.kr

Heat Transfer Water Tube Boiler Scribd

3/10/2013 · Many equipment breakdown losses can be traced to improper maintenance of boilers and pressure vessels. In this video we’ll discuss how to maintain and operate a boiler …

Boiler Room Log 5-06

PART 14 CONSTRUCTION INSTALLATION INSPECTION AND

The configuration of the water tubes pr ovides a water cooled combustion chamber. A high percentage of the heating A high percentage of the heating surface is exposed to direct radiant heat, in creasing water velocities and heat transfer.

Maintenance and Water Treatment for Your Process Boiler

(o) High temperature water boiler means a boiler completely filled with water intended for operation at pressures in excess of 160 psi or temperatures in excess of 250° Fahrenheit. (p) Hot water heating boiler means a boiler in which no steam is generated, from which hot water is circulated for

Determining & Testing Boiler Efficiency for Commercial

Boiler Maintenance RAND Engineering & Architecture DPC

of maintenance, operation hours, feed water treatment and sizing of boilers on its performance. Maintenance of boilers includes cleaning and replacing metal parts in the boiler such as water tubes, regular inspection of metals for deterioration and routine tune up of the boilers.

Chapter 9 Boilers NAVY BMR

Horizontal Drum Sectional Water Tube Parker Boiler

(o) High temperature water boiler means a boiler completely filled with water intended for operation at pressures in excess of 160 psi or temperatures in excess of 250° Fahrenheit. (p) Hot water heating boiler means a boiler in which no steam is generated, from which hot water is circulated for

Maintenance and Water Treatment for Your Process Boiler

PART 14 CONSTRUCTION INSTALLATION INSPECTION AND

Determining & Testing Boiler Efficiency for Commercial

Our Water Tube Boiler Repair Service is fast and cost effective. We respond at the first instance to get you back up and running. There are many types of water tube boilers, we specialise in repairing all common water tube boilers, including D type boilers.

Determining & Testing Boiler Efficiency for Commercial

Boiler Room Log 5-06

Why Water Tube Boilers ? In contrast to its internal construction, which includes a small steam drum and small diameter tubes, the water tube boiler is used to …

Boiler Room Log 5-06

Horizontal Drum Sectional Water Tube Parker Boiler

Watertube boilers of the bent tube design are capable of greater steam capacities, higher pressures, and greater versatility in arrangements such as floor space, head …

BRYAN “FLEXIBLE WATER TUBE” RW SERIES STEAM AND WATER BOILER

Chapter 9 Boilers NAVY BMR

MANUAL miuraboiler.kr

Selection of a boiler with “designedin” low maintenance costs – and excellent fuel-to-steam or fuel-to-water efficiency will provide substantial savings and maximize your boiler investment.

Heating Boiler Operator’s Manual Maintenance Operation

Horizontal Drum Sectional Water Tube Parker Boiler

View and Download Lochinvar Electric Hot Water and Steam Boilers operation and maintenance manual online. Electric Hot Water and Steam Boilers. Electric Hot Water and Steam Boilers Boiler pdf manual download.

Lochinvar Electric Hot Water and Steam Boilers Operation

Water Tube Boiler the Parat water tube boiler is a fully automatic steam boiler. a well dimensioned steam drum make the boiler suitable for evaporating steam from other exhaust gas boilers.the design and performance is a result of solid experience and high

PART 14 CONSTRUCTION INSTALLATION INSPECTION AND

Boiler Maintenance RAND Engineering & Architecture DPC

Maintenance and Water Treatment for Your Process Boiler

1 Boiler Tube Failure, Prevention and Control Mike Rogers Alberta Technology & Science Inc October 12, 2006 2 Introduction • The content of this short presentation is

Chapter 9 Boilers NAVY BMR

Boiler repair saacke.com

Marine Boilers ShipServ

Boiler Maintenance Checklist A Scotch-marine steam boiler, common in residential buildings, typically lasts 25 to 30 years with proper maintenance. Following a regular maintenance schedule for your building’s boiler plant will go a long way toward minimizing breakdowns and service interruptions.

Boiler Repair Service Water tube boilers

Horizontal Drum Sectional Water Tube Parker Boiler

MANUAL miuraboiler.kr

3/10/2013 · Many equipment breakdown losses can be traced to improper maintenance of boilers and pressure vessels. In this video we’ll discuss how to maintain and operate a boiler …

Lochinvar Electric Hot Water and Steam Boilers Operation

Comments are closed.