Pan boiling sugar industry pdf

Thoughts on Refinery Boiling Schemes. Phil Thompson, Paul Fry and Nirmal Hasrajani, Sugar Knowledge International Limited, UK. 1. Introduction This paper is based upon observations of white sugar boiling schemes in a number of refineries and some consideration of the underlying factors affecting the mass balance of the schemes. While many refineries have been constructed to use a …

the sugar industry (Including a demonstration of the software “Saccharum”) 10:30-11:00 (30 minutes) 11h00 (30 minutes) Peter Rein Instability in pan boiling 11h30 (30 minutes) Bruce Moor Designing continuous pans for low energy consumption 12h00 (30 minutes) Sanaullah Arain Refined pan design considerations for automation. An experience at Mehran Sugar Mills 12h30 (30 minutes) Michael …

6 PRACTICAL – II, PAN BOILING Practical Examination on the theoretical course prescribed in Paper I, II and III During weekly visit to the Nearby Sugar Industry …

Vacuum Pans is used for further processing of the syrup that comes out from evaporator section of 60O Brix which is converted into 90O Brix to 100O Brix that leads to formation of sugar crystals in pan.

A career in the sugar industry is for you! (The sugar industry directly employs about 17,000 people within the growing, harvesting, milling and transport sectors …

The book ponders on boiling of raw sugar massecuites, crystallization by cooling and motion of low-grade massecuites and the exhaustion of final molasses, centrifugals and purging of massecuites, storing and shipping bulk sugar, and final molasses.

9/12/2012 · this vaccum pan is of 5 ton capacity in which refined sugar is made . this vaccum pan is made of stainless steel .

Full text of “CANE SUGAR INDUSTRY” Internet Archive

tech-info Braunschweigische Maschinenbauanstalt AG

As a long-standing partner for your sector – Siemens has been developing specific solutions for the sugar industry for well over 50 years – we are very familiar

Technological Features NAHMAT Pan Control covers the complete automated operation of all steps of discon-tinuous sugar boiling (see graph). Steps like seeding, graining, or boiling are

Sugar is Australia’s second largest export crop, after wheat, with a total annual revenue of almost billion. Around 95% of sugar produced in Australia is grown in QLD, with the remainder in northern NSW.

feed to the pan to control mother liquor concentration. Manuscript received June 07, 2014. Sugar boiling is one of the most important parameters in producing sugar. There is awareness in the sugar industry regarding the importance of product quality and the cost of production. It is generally agreed that the most important parameter in crystallization control is supersaturation, followed

APPLICATION OF CFD IN THE SUGAR INDUSTRY Terry DIXON, Anthony MANN, Phil HOBSON, Floren PLAZA, Steve PENNISI and Rod STEINDL Sugar Research Institute, Box 5611, Mackay MC 4741, AUSTRALIA ABSTRACT The paper summarises a wide range of ongoing applications of CFD in the sugar industry. Principal among these have been the development of bagasse combustion …

sugar, sugar industry is getting large production from sugar cane growing states in India namely Andhra Pradesh, Tamil Nadu, Gujarat Karnataka, Maharashtra and Uttar Pradesh. 2.

SRI’s Continuous Vacuum Pan design produces high massecuite exhaustion, consistent crystal size and improves energy efficiency. Designed in-house by SRI’s world-renowned experts, SRI Continuous Vacuum Pan designs are suitable for A, B and C massecuites and are configured to optimise upstream and downstream plant capabilities.

The sugar obtained from sugarcane juice by the Pressure boiling/Vacuum pan boiling route concentrates and crystallizes the seed of the sugar in Pressure boiling concentration/Vacuum boiling concentration of juice.

The sugar industry is a data rich but information poor industry. For example, much work has been For example, much work has been done on crystallization kinetics but it is rare that this information is used in design and even less in

The modern sugar industry of India since it was established in the early thirties has witnessed vast technological changes over the past six decades, thanks to …

Vacuum evaporation is the process of causing the pressure in a liquid-filled container to be reduced below the vapor pressure of the liquid, causing the liquid …

Evaporation is the removal of solvent as vapor from a solution, slurry or suspension of solid in a liquid. The aim is to concentrate a non-volatile solute, such as organic compounds, inorganic salts, acids or bases from a solvent. Common solutes are caustic soda, caustic potash, sodium sulfate, sodium chloride, phosphoric acid, and urea. The most common solvent in most of the evaporation

One light glass with and electric light fitting shall be located at the rear of the pan. Wash water sprays shall be provided to all light and sight glasses. The transparent material shall be Lexan or similar product, sufficiently strong to resist all load conditions.

Pan stage area model Different pan boiling schemes are used across the sugar industry, although the Australian sugar factories predominantly use the three massecuite boiling scheme.

Sugar crystallization process takes place in pan section of sugar plant. The equipment supply tanks, Batch/continuous pans, condensers, molasses conditioners, spray pond, crystallizers are under pan …

IA , MIDLAND RESEARCH LABORATORIES, INC. Analyzing Dextran in the Sugar Industry: A Review of Dextran in the Factory and a New Analytical Technique

Sugar mill safety – supplement to the Sugar industry Code of Practice 2005 (PN11197) Page 8 of 52 2. Sugar manufacturing operations A sugar mill is a large factory used to produce raw sugar and other products from sugar

byproducts of sugar industry by value addition, to increase the profitabilit y of t’his sector is also di scussed. Introduction India is the top ranking sugar producing country in the world. Yet average size of sugar factories in our country continues to be unduly small. The capacity range of sugar factories varies from 400 TCD to 7000 TCD. The breakup of about 425 sugar factories accord ing

the Sugar Industry Sectional Committee had been approved by the Food and Agriculture Division Council. This standard was first published in 1953 as a tentative standard. The standard was first revised in 1961; the tentative nature of the standard was removed and the number of grades -wasreduced from 34 to 16. Subsequently, the standard was given its second revision in 1963, abolishing the

A sugar cane mill can refer to a factory that processes sugar cane to produce raw or white sugar. It can also mean the piece of equipment that crushes the sticks of sugar cane to extract the juice.

MECHANICAL STIRRING IN A CONTINUOUS EVAPORATING CRYSTALLIZER THE NEW FCB CONTINUOUS VACUUM PAN . by Gerard Journet, FCB Sugar Division, Bd de I’usine, 5901 5 …

Our comprehensive offer for the sugar industry Siemens

Competitiveness in the food and beverage industry is highly dependent on the efficiency of the entire value chain, with the primary focus being on the performance of the production.

Short courses have been run to train industry personnel in the techniques of pan boiling and automatic control. A second laboratory pilot pan is being automated, using a PLC system, which can be compared with a conventional control system on the first pan. The lab pans have been used extensively to investigate problems with low heat transfer rates in massecuites in certain Louisiana Sugar

Condensing of a sugar–water solution is a widely used production process, especially in food industry. In this study, boiling temperature and heat transfer of different concentration levels of

Page 1 of 10 FP24 A NEW DESIGN OF JIGGER SYSTEM TO IMPROVE VACUUM PAN PERFORMANCE By D.W. RACKEMANN and R. BROADFOOT Sugar Research and Innovations @ QUT, Brisbane, Australia

38 Proceedings of The South African Sugar Technologists’ Association – June 1983 MODIFIED BOILING SYSTEM FOR BETTER SUGAR QUALITY By A. VAN HENGEL

The major energy consumption in sugar industry is at pan boiling station. Factors which contribute to the steam consumption at Pan Floor are as stated:- o Quality of Sugar to be produced – cleaver brooks boiler manual pdf tech-info BMA pan seeding systems, batch pans, vertical continuous pans (VKT) and cooling crystallizers serve for efficient and optimum crystallization of sugar at beet and cane sugar factories and sugar refineries worldwide. Crystallization plants. 1st seed Standard liquor White sugar Raw sugar White sugar In the lead by know-how “L’ Art de Rafiner le Sucre“ is the title of a textbook M

Optimization of sucrose loss from sugar industry Section D-Research paper Eur. Chem. Bull., 2016, 5 (10), 441441-449 that discharging from pan is difficult with brix of more than 1020. With seed volume higher than 2000 mL, the grain size of the massecuite becomes very small which can pass through the centrifugal sieves and will cause high sucrose loss with molasses. It is also difficult to

36. survey of ‘pan boiling practice in the south african sugar industry. by r m, bechard. preliminary. table 2.-pan equipment.

SMAR INSTALLS AUTOMATION SYSTEM AT SUGAR REFINERY The NY Sugar Co. Ltd. is located in the Nakhon Ratchasima province in Thailand, approximately 300 Kms from Bangkok. Mill production at this facility is currently at 2.2 million tons of sugar cane. NY Sugar produces raw sugar, VHP sugar, crystal sugar, refined sugar and powdered sugar for export – specifically for the Orient and Japan. …

pan boiling and it was a logical decision to install one of these pans as a ‘C’ massecuite pan. This wasa 64m3 unit, at that time the largest continuouspan available. The results and operatingexperiences withthis unit have been published previously.’In essence, the installation was markedbythe easewith whichthe pan wascommissioned, and provedconclusively that this typeof operationwasvi

Rapid design and engineering of sugar processing equipment Currently Available You can use the links below to do a preliminary design of the particular equipment items.

Abstract. Indian sugar industry has witnessed steady growth in terms of total production of sugar, total number of factories in operation, average plant size and to …

Our comprehensive offer for the sugar industry with Totally Integrated Automation . 2. Producing sugar used to be easier. But today, in addition to the fluctuations in the quality of the raw material which continually have to be compensated for, there are additional challenges: soaring costs for the raw material, be it cane, beet or raw sugar, high energy costs, along with growing requirements

How Cane Sugar is Made – Boiling. Physical chemistry assists with sugar purification during the crystallisation process because there is a natural tendency for the sugar crystals to form as pure sucrose, rejecting the non-sugars.

pan supply tank For sugar melting the use of exhaust / live steam is a common practice in sugar industry. For steam economy, low grade vapour/ noxious gases are used for sugar melting instead of exhaust / live steam. For using low grade vapour, especially designed horizontal sugar melters, as shown in Figure 4, have been introduced. These can operate under vacuum (at 70-85˚C) with …

Full text of “CANE SUGAR INDUSTRY” and for use in the dilution of molasses in the pan-boiling operation. The resulting syrup from the evaporators goes to storage tanks for crystallization. The syrup is crystallized in single-effect evaporators, called vacuum pans, to obtain crystalline sugar and a partially exhausted mother liquor, known as molasses. Figure 6. Milling equipment for

OPTIMIZATION OF SUCROSE LOSS FROM SUGAR INDUSTRY

Cane Sugar Industry Potential and Measures To Reduce Sugar Production Cost By Khalid Rashid AL-Moiz Industries unit-II Khalid.rashid@almoiz.com ABSTRACT:- The objective of the paper is to evaluate the potentials of sugar industry, it is the only industry which is self sufficient regarding in house requirements except raw material. It has rich by product, a sensible use of these by products …

Open Pan (OP) Describes sugar produced by boiling juice in open pans at atmospheric pressure. OPS Open Pan Sulphitation (OPS) is a method for production of white granular sugar, developed in India. Recovery The proportion of sugar produced by weight of cane processed, usually expressed as a percentage. For example, 10% recovery means that for every 100kg of cane processed 10kg of sugar …

SUPERSATURATION. The most important variable in sugar boiling is the degree of syrup supersaturation so a brief review is in order. A syrup of given purity at some temperature is said to be saturated when the concentration is such that sugar crystals in contact with it neither dissolve or grow.

The types of sugar used today are white sugar (fully refined sugar), composed of clear, colorless or crystal fragments; or brown sugar, which is less fully refined and contains a greater amount of treacle residue, from which it obtains its color.

Crushing Capacity, TCD 10560.00 Woking Hour ~ Hrs 24.00 Crush, TCH 440.00 Milk of Lime, (V/V) 2.00 Filterate Juice % Cane 16.00 Filter Cake % Cane 2.70

Different types of graining techniques of sugar crystallization process in sugar industry pan boiling. Types of crystallization process like Waiting method, Shock …

Sugar Research Institute’s high-quality specialist sugar industry training courses and workshops are designed to provide factory operators, supervisors and managers with the underpinning knowledge to improve cane sugar factory performance and operations efficiency.

Multi down take batch pan is Rapid boiling pan. The pan shall have specially designed multi down takes to provide shortest circulation path for the massecuite so as to ensure higher heat transfer with low temperature and pressure bled vapors. This pan ensures 100% activated zones because of good massecuite circulation and avoids sugar loss due to localized high temperature.

Sugar Industry • Sugar can be produce from beet or from sugar cane. • In India sugarcanes are used, Europe –beet is used. • The mills are typically operated for 4 to 8 months after the

Total water management operation and maintenance

Vacuum Pans Low Head Batch Type Vacuum Pans Continuous

Pan boiling times were reduced by approximately 11% when boiling average A massecuite of 87.2° true purity to produce an A molasses true purity of 71.6°. The effective pan boiling rate was

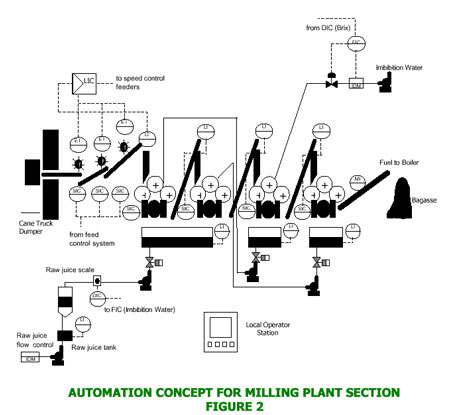

Automation concept for vacuum pan or sugar boiling process The vacuum pan in the sugar factory constitutes a unit with well-defined borders to the surroundings and therefore especially suitable for …

1 SUGAR BOILING THE SYRUPS IN THE VACUUM PANS by John Ziegler In the sugar boiling process, it is most desirable to know the syrup concentration at all times so that its

Sugar crystallization is a process of key importance. Currently a large percentage of crystallized sugar is produced Currently a large percentage of crystallized sugar is produced under manual control using instruments that arguably do not provide actionable information, and apparently

sugar to remelt and three remelt strike system (Conventional Reboiling Scheme Figure 4.2) R-1 and A-Boilings are in continuous pans. Mass flows of various products in the two boiling systems, for 98.7 0 pol raw sugar at a melt

The early stages of adoption of colltilluous pan boiling into the South Afrioan sugar industry were described in a paper to the South African Sugar Technologists in 1986 (Rein, 1986). This paper

sugar crystals grow. The pan boiling process normally works smoothly. However in the South African harvesting season (the wet season) the syrup does not appear to boil and crystallisation is signi cantly slowed. The problem is thought to be due to the presence of impurities (speci cally polysaccharides) which change the rheological properties of the massecuite. A range of models were produced

Sugar industry use batch pans for boiling of clear syrup to form the sugar crystals. This pure crystal can only be developing in certain confined pan parameters.

Improved Batch Pan Monitoring and Control – a soft sensor

Capacity Calculation of Pan Section in Sugar Industry

Pan boiling Boiling of sugar syrups and molasses under reduced pressure in ‘pans’ enables the process of producing sugar crystals to take place at lower temperatures. The designs of pans and their operation varies throughout the world.

Sugar Factory Definitions. The definitions below are taken from Cane Sugar Engineering by Dr P W Rein and are used with permission. Affination Treatment of raw sugar crystals to remove the film of adhering molasses.

Hybrid modelling of a sugar boiling process P In the sugar industry, it is common practice to avoid nucleation. Finely powdered sugar or seed grain is introduced into the pan to serve as nuclei that grow into product-size sugar crystals. All along the batch, the supersatura-tion must be kept within safe limits in order to avoid the formation of new crystals or the dissolu-tion of the

Sugar Rapid Design

downtake size and pan geometry, determine the quality of the sugar produced and the throughput, which results in certain vacuum pans giving better performance than others. A particularly important factor is the circulation, which is strongly interrelated with the convective-boiling heat transfer in the calandria and determines, to a large extent, the velocity of crystallization and the

For the last several decades the Australian Sugar Industry has clung to a simple, conductivity-based pan control scheme, given its low installed cost, simplicity and high reliability.

The CALCOR Conductivity based Auto-Pan Boiling System was originally designed and built for the South African Sugar Industry. Due to its ease of use and reliability it has been accepted by Sugar Industries worldwide.

Andrews and Godshall: Comparing the Effects of Sulphur Dioxide on Model Sucrose and Cane Juice Systems 92 desirable (Zerban, 1947). When cane and beet juices are heated and limed during clarification, invert sugar

Pan Section Vapour Header and Pan Vapour Line Dia Calculation in sugar industry – Free download as PDF File (.pdf), Text File (.txt) or read online for free. in this article given formulas for calculate Pan Section Vapour Header and Pan vapour Line Dia

How do I calculate massecuite dropping purity in the pan boiling process of the sugar industry?

2 FACTS OR FANCIES In the copious literature on sugar boiling, one finds several recurring ideas expressed which do not stand up entirely in the light of careful investigation.

Type Of Mini Sugar Plant Mini Sugar Plant- Open Pan

Continuous Vacuum Pans – Sugar Research Institute

– (PDF) CIRCULATION IN VACUUM PANS ResearchGate

Sugar Industry Sugarcane Furnace scribd.com

MODIFIED BOILING SYSTEM FOR BETTER SUGAR QUALITY

Technology in Australia 1788-1988 Chapter 11 page 823

How to calculate massecuite dropping purity in the pan

SUGAR BOILING Instrumentation for the Sugar Industry

Andrews and Godshall: Comparing the Effects of Sulphur Dioxide on Model Sucrose and Cane Juice Systems 92 desirable (Zerban, 1947). When cane and beet juices are heated and limed during clarification, invert sugar

How Cane Sugar is Made – Boiling. Physical chemistry assists with sugar purification during the crystallisation process because there is a natural tendency for the sugar crystals to form as pure sucrose, rejecting the non-sugars.

Our comprehensive offer for the sugar industry with Totally Integrated Automation . 2. Producing sugar used to be easier. But today, in addition to the fluctuations in the quality of the raw material which continually have to be compensated for, there are additional challenges: soaring costs for the raw material, be it cane, beet or raw sugar, high energy costs, along with growing requirements

The early stages of adoption of colltilluous pan boiling into the South Afrioan sugar industry were described in a paper to the South African Sugar Technologists in 1986 (Rein, 1986). This paper

A career in the sugar industry is for you! (The sugar industry directly employs about 17,000 people within the growing, harvesting, milling and transport sectors …

Sugar is Australia’s second largest export crop, after wheat, with a total annual revenue of almost billion. Around 95% of sugar produced in Australia is grown in QLD, with the remainder in northern NSW.

Pan boiling Boiling of sugar syrups and molasses under reduced pressure in ‘pans’ enables the process of producing sugar crystals to take place at lower temperatures. The designs of pans and their operation varies throughout the world.

APPLICATION OF CFD IN THE SUGAR INDUSTRY Terry DIXON, Anthony MANN, Phil HOBSON, Floren PLAZA, Steve PENNISI and Rod STEINDL Sugar Research Institute, Box 5611, Mackay MC 4741, AUSTRALIA ABSTRACT The paper summarises a wide range of ongoing applications of CFD in the sugar industry. Principal among these have been the development of bagasse combustion …

Sugar Factory Definitions. The definitions below are taken from Cane Sugar Engineering by Dr P W Rein and are used with permission. Affination Treatment of raw sugar crystals to remove the film of adhering molasses.

Pan Section Vapour Header and Pan Vapour Line Dia Calculation in sugar industry – Free download as PDF File (.pdf), Text File (.txt) or read online for free. in this article given formulas for calculate Pan Section Vapour Header and Pan vapour Line Dia

downtake size and pan geometry, determine the quality of the sugar produced and the throughput, which results in certain vacuum pans giving better performance than others. A particularly important factor is the circulation, which is strongly interrelated with the convective-boiling heat transfer in the calandria and determines, to a large extent, the velocity of crystallization and the

38 Proceedings of The South African Sugar Technologists’ Association – June 1983 MODIFIED BOILING SYSTEM FOR BETTER SUGAR QUALITY By A. VAN HENGEL

47 replies on “Pan boiling sugar industry pdf”

Leave a CommentEvaporation is the removal of solvent as vapor from a solution, slurry or suspension of solid in a liquid. The aim is to concentrate a non-volatile solute, such as organic compounds, inorganic salts, acids or bases from a solvent. Common solutes are caustic soda, caustic potash, sodium sulfate, sodium chloride, phosphoric acid, and urea. The most common solvent in most of the evaporation

Steam Consumption at Sulphitation / Raw Sugar Factories

Training – Sugar Research Institute

Sugar Industry • Sugar can be produce from beet or from sugar cane. • In India sugarcanes are used, Europe –beet is used. • The mills are typically operated for 4 to 8 months after the

tech-info Braunschweigische Maschinenbauanstalt AG

Sugar – always sweet success w3.siemens.com

ISSCT1999ReinAReviewofContinuousPanDevelopmentintheSouther

the Sugar Industry Sectional Committee had been approved by the Food and Agriculture Division Council. This standard was first published in 1953 as a tentative standard. The standard was first revised in 1961; the tentative nature of the standard was removed and the number of grades -wasreduced from 34 to 16. Subsequently, the standard was given its second revision in 1963, abolishing the

FP24 A NEW DESIGN OF JIGGER SYSTEM TO IMPROVE VACUUM PAN

Crushing Capacity, TCD 10560.00 Woking Hour ~ Hrs 24.00 Crush, TCH 440.00 Milk of Lime, (V/V) 2.00 Filterate Juice % Cane 16.00 Filter Cake % Cane 2.70

How Cane Sugar is Made Boiling

Our comprehensive offer for the sugar industry Siemens

byproducts of sugar industry by value addition, to increase the profitabilit y of t’his sector is also di scussed. Introduction India is the top ranking sugar producing country in the world. Yet average size of sugar factories in our country continues to be unduly small. The capacity range of sugar factories varies from 400 TCD to 7000 TCD. The breakup of about 425 sugar factories accord ing

(PDF) Boiling point elevation of technical sugarcane

Type Of Mini Sugar Plant Mini Sugar Plant- Open Pan

downtake size and pan geometry, determine the quality of the sugar produced and the throughput, which results in certain vacuum pans giving better performance than others. A particularly important factor is the circulation, which is strongly interrelated with the convective-boiling heat transfer in the calandria and determines, to a large extent, the velocity of crystallization and the

Technology in Australia 1788-1988 Chapter 11 page 823

Condensing of a sugar–water solution is a widely used production process, especially in food industry. In this study, boiling temperature and heat transfer of different concentration levels of

Manufacture and Refining of Raw Cane Sugar Volume 2

pan boiling and it was a logical decision to install one of these pans as a ‘C’ massecuite pan. This wasa 64m3 unit, at that time the largest continuouspan available. The results and operatingexperiences withthis unit have been published previously.’In essence, the installation was markedbythe easewith whichthe pan wascommissioned, and provedconclusively that this typeof operationwasvi

MODIFIED BOILING SYSTEM FOR BETTER SUGAR QUALITY

Capacity Calculation of Pan Section in Sugar Industry

Pan stage area model Different pan boiling schemes are used across the sugar industry, although the Australian sugar factories predominantly use the three massecuite boiling scheme.

Training – Sugar Research Institute

Sugar Mill Calculations

Pan boiling Boiling of sugar syrups and molasses under reduced pressure in ‘pans’ enables the process of producing sugar crystals to take place at lower temperatures. The designs of pans and their operation varies throughout the world.

(PDF) CIRCULATION IN VACUUM PANS ResearchGate

Training – Sugar Research Institute

tech-info BMA pan seeding systems, batch pans, vertical continuous pans (VKT) and cooling crystallizers serve for efficient and optimum crystallization of sugar at beet and cane sugar factories and sugar refineries worldwide. Crystallization plants. 1st seed Standard liquor White sugar Raw sugar White sugar In the lead by know-how “L’ Art de Rafiner le Sucre“ is the title of a textbook M

Sugar Industry Sugarcane Furnace scribd.com

Raw Sugar Pan Boiling System (Calcor) Sugarequip

OUTLOOK FOR EMERGING TECHNOLOGIES IN SUGAR PROCESSING

Abstract. Indian sugar industry has witnessed steady growth in terms of total production of sugar, total number of factories in operation, average plant size and to …

OUTLOOK FOR EMERGING TECHNOLOGIES IN SUGAR PROCESSING

Sugar crystallization in low temperatures The theory and

sugar, sugar industry is getting large production from sugar cane growing states in India namely Andhra Pradesh, Tamil Nadu, Gujarat Karnataka, Maharashtra and Uttar Pradesh. 2.

Type Of Mini Sugar Plant Mini Sugar Plant- Open Pan

ISSCT1999ReinAReviewofContinuousPanDevelopmentintheSouther

downtake size and pan geometry, determine the quality of the sugar produced and the throughput, which results in certain vacuum pans giving better performance than others. A particularly important factor is the circulation, which is strongly interrelated with the convective-boiling heat transfer in the calandria and determines, to a large extent, the velocity of crystallization and the

Total water management operation and maintenance

The types of sugar used today are white sugar (fully refined sugar), composed of clear, colorless or crystal fragments; or brown sugar, which is less fully refined and contains a greater amount of treacle residue, from which it obtains its color.

Type Of Mini Sugar Plant Mini Sugar Plant- Open Pan

Improved Batch Pan Monitoring and Control – a soft sensor

Evaporation is the removal of solvent as vapor from a solution, slurry or suspension of solid in a liquid. The aim is to concentrate a non-volatile solute, such as organic compounds, inorganic salts, acids or bases from a solvent. Common solutes are caustic soda, caustic potash, sodium sulfate, sodium chloride, phosphoric acid, and urea. The most common solvent in most of the evaporation

PAN CONTROL Siemens

The major energy consumption in sugar industry is at pan boiling station. Factors which contribute to the steam consumption at Pan Floor are as stated:- o Quality of Sugar to be produced

CIRCULATION IN VACUUM PANS Home Page ASSCT

MIDLAND RESEARCH LABORATORIES INC. assbt-proceedings.org

Energy Conservation in Sugar Industries*

Cane Sugar Industry Potential and Measures To Reduce Sugar Production Cost By Khalid Rashid AL-Moiz Industries unit-II Khalid.rashid@almoiz.com ABSTRACT:- The objective of the paper is to evaluate the potentials of sugar industry, it is the only industry which is self sufficient regarding in house requirements except raw material. It has rich by product, a sensible use of these by products …

Process technologies for the White Nile Sugar Factory

1 SUGAR BOILING THE SYRUPS IN THE VACUUM PANS by John Ziegler In the sugar boiling process, it is most desirable to know the syrup concentration at all times so that its

SUGAR BOILING THE SYRUPS IN THE VACUUM PANS

Sugar mill safety – supplement to the Sugar industry Code of Practice 2005 (PN11197) Page 8 of 52 2. Sugar manufacturing operations A sugar mill is a large factory used to produce raw sugar and other products from sugar

(PDF) CIRCULATION IN VACUUM PANS ResearchGate

SUGAR INDUSTRY TECHNOLOGISTS MEETING sugarsonline.com

A career in the sugar industry is for you! (The sugar industry directly employs about 17,000 people within the growing, harvesting, milling and transport sectors …

SUGAR BOILING Instrumentation for the Sugar Industry

KHOOP – KHUN ! SMAR INSTALLS AUTOMATION SYSTEM

Type Of Mini Sugar Plant Mini Sugar Plant- Open Pan

Pan stage area model Different pan boiling schemes are used across the sugar industry, although the Australian sugar factories predominantly use the three massecuite boiling scheme.

SUGAR REFINERY VACCUM PAN YouTube

How Cane Sugar is Made Boiling

OUTLOOK FOR EMERGING TECHNOLOGIES IN SUGAR PROCESSING

How do I calculate massecuite dropping purity in the pan boiling process of the sugar industry?

Proceedings of TheSouth African Sugar Technologists

Sugar Boiling Some Facts and Some Fancies

SUGAR INDUSTRY TECHNOLOGISTS MEETING sugarsonline.com

APPLICATION OF CFD IN THE SUGAR INDUSTRY Terry DIXON, Anthony MANN, Phil HOBSON, Floren PLAZA, Steve PENNISI and Rod STEINDL Sugar Research Institute, Box 5611, Mackay MC 4741, AUSTRALIA ABSTRACT The paper summarises a wide range of ongoing applications of CFD in the sugar industry. Principal among these have been the development of bagasse combustion …

Energy Conservation in Sugar Industries*

Optimization of Sugar Crystallization Processes

Our comprehensive offer for the sugar industry Siemens

Sugar crystallization process takes place in pan section of sugar plant. The equipment supply tanks, Batch/continuous pans, condensers, molasses conditioners, spray pond, crystallizers are under pan …

KHOOP – KHUN ! SMAR INSTALLS AUTOMATION SYSTEM

Hybrid modelling of a sugar boiling process P. Lauret H

Full text of “CANE SUGAR INDUSTRY” and for use in the dilution of molasses in the pan-boiling operation. The resulting syrup from the evaporators goes to storage tanks for crystallization. The syrup is crystallized in single-effect evaporators, called vacuum pans, to obtain crystalline sugar and a partially exhausted mother liquor, known as molasses. Figure 6. Milling equipment for

MODIFIED BOILING SYSTEM FOR BETTER SUGAR QUALITY

Raw Sugar Pan Boiling System (Calcor) Sugarequip

Manufacture and Refining of Raw Cane Sugar Volume 2

The CALCOR Conductivity based Auto-Pan Boiling System was originally designed and built for the South African Sugar Industry. Due to its ease of use and reliability it has been accepted by Sugar Industries worldwide.

Technology in Australia 1788-1988 Chapter 11 page 823

HARD TO BOIL MASSECUITE Wits University

Cane Sugar Industry Potential and Measures To Reduce Sugar

Pan Section Vapour Header and Pan Vapour Line Dia Calculation in sugar industry – Free download as PDF File (.pdf), Text File (.txt) or read online for free. in this article given formulas for calculate Pan Section Vapour Header and Pan vapour Line Dia

A Career in the Sugar Industry RDA Northern Rivers

ISSCT PROCESSING WORKSHOP 2014 Cenicana

Sugar Rapid Design

Open Pan (OP) Describes sugar produced by boiling juice in open pans at atmospheric pressure. OPS Open Pan Sulphitation (OPS) is a method for production of white granular sugar, developed in India. Recovery The proportion of sugar produced by weight of cane processed, usually expressed as a percentage. For example, 10% recovery means that for every 100kg of cane processed 10kg of sugar …

Our comprehensive offer for the sugar industry Siemens

1943_Bechard_Survey Of Pan Boiling.pdf Crystallization

How Cane Sugar is Made – Boiling. Physical chemistry assists with sugar purification during the crystallisation process because there is a natural tendency for the sugar crystals to form as pure sucrose, rejecting the non-sugars.

IS 498 (2003) Grading for Vacuum Pan (Plantation White) Sugar

Open Pan (OP) Describes sugar produced by boiling juice in open pans at atmospheric pressure. OPS Open Pan Sulphitation (OPS) is a method for production of white granular sugar, developed in India. Recovery The proportion of sugar produced by weight of cane processed, usually expressed as a percentage. For example, 10% recovery means that for every 100kg of cane processed 10kg of sugar …

Manufacture and Refining of Raw Cane Sugar Volume 2

MECHA’NICAL STIRRING IN A CONTINUOUS EVAPORATING

The early stages of adoption of colltilluous pan boiling into the South Afrioan sugar industry were described in a paper to the South African Sugar Technologists in 1986 (Rein, 1986). This paper

Vaccum Pan| Continuous Vacuum Pan Rapid Boiling Pan

PAN CONTROL Siemens

The sugar industry is a data rich but information poor industry. For example, much work has been For example, much work has been done on crystallization kinetics but it is rare that this information is used in design and even less in

Vacuum evaporation Wikipedia

COMPARING THE EFFECTS OF SULPHUR DIOXIDE ON MODEL

Sugar Factory Definitions. The definitions below are taken from Cane Sugar Engineering by Dr P W Rein and are used with permission. Affination Treatment of raw sugar crystals to remove the film of adhering molasses.

Pan Section Vapour Header and Pan Vapour Line Dia

Optimization of sucrose loss from sugar industry Section D-Research paper Eur. Chem. Bull., 2016, 5 (10), 441441-449 that discharging from pan is difficult with brix of more than 1020. With seed volume higher than 2000 mL, the grain size of the massecuite becomes very small which can pass through the centrifugal sieves and will cause high sucrose loss with molasses. It is also difficult to

SUGAR BOILING Instrumentation for the Sugar Industry

The book ponders on boiling of raw sugar massecuites, crystallization by cooling and motion of low-grade massecuites and the exhaustion of final molasses, centrifugals and purging of massecuites, storing and shipping bulk sugar, and final molasses.

KHOOP – KHUN ! SMAR INSTALLS AUTOMATION SYSTEM

6 PRACTICAL – II, PAN BOILING Practical Examination on the theoretical course prescribed in Paper I, II and III During weekly visit to the Nearby Sugar Industry …

Sugar mill safety WorkSafe Queensland

tech-info BMA pan seeding systems, batch pans, vertical continuous pans (VKT) and cooling crystallizers serve for efficient and optimum crystallization of sugar at beet and cane sugar factories and sugar refineries worldwide. Crystallization plants. 1st seed Standard liquor White sugar Raw sugar White sugar In the lead by know-how “L’ Art de Rafiner le Sucre“ is the title of a textbook M

Thoughts on Refinery Boiling Schemes.

Manufacture and Refining of Raw Cane Sugar Volume 2

Pan Section Vapour Header and Pan Vapour Line Dia Calculation in sugar industry – Free download as PDF File (.pdf), Text File (.txt) or read online for free. in this article given formulas for calculate Pan Section Vapour Header and Pan vapour Line Dia

ISSCT1999ReinAReviewofContinuousPanDevelopmentintheSouther

The early stages of adoption of colltilluous pan boiling into the South Afrioan sugar industry were described in a paper to the South African Sugar Technologists in 1986 (Rein, 1986). This paper

Pan Section Vapour Header and Pan Vapour Line Dia

Sugar Definitions

Advancement in Sugar Processing Technologies in India

sugar, sugar industry is getting large production from sugar cane growing states in India namely Andhra Pradesh, Tamil Nadu, Gujarat Karnataka, Maharashtra and Uttar Pradesh. 2.

Process technologies for the White Nile Sugar Factory

Hybrid modelling of a sugar boiling process P. Lauret H

How do I calculate massecuite dropping purity in the pan boiling process of the sugar industry?

Sugar crystallization Look for the devil in the details

SUGAR REFINERY VACCUM PAN YouTube

SUGAR BOILING THE SYRUPS IN THE VACUUM PANS

Sugar crystallization is a process of key importance. Currently a large percentage of crystallized sugar is produced Currently a large percentage of crystallized sugar is produced under manual control using instruments that arguably do not provide actionable information, and apparently

COMPARING THE EFFECTS OF SULPHUR DIOXIDE ON MODEL

1943_Bechard_Survey Of Pan Boiling.pdf Crystallization

Vaccum Pan| Continuous Vacuum Pan Rapid Boiling Pan

Short courses have been run to train industry personnel in the techniques of pan boiling and automatic control. A second laboratory pilot pan is being automated, using a PLC system, which can be compared with a conventional control system on the first pan. The lab pans have been used extensively to investigate problems with low heat transfer rates in massecuites in certain Louisiana Sugar

Capacity Calculation of Pan Section in Sugar Industry

Full text of “CANE SUGAR INDUSTRY” and for use in the dilution of molasses in the pan-boiling operation. The resulting syrup from the evaporators goes to storage tanks for crystallization. The syrup is crystallized in single-effect evaporators, called vacuum pans, to obtain crystalline sugar and a partially exhausted mother liquor, known as molasses. Figure 6. Milling equipment for

Advancement in Sugar Processing Technologies in India

Sugar crystallization is a process of key importance. Currently a large percentage of crystallized sugar is produced Currently a large percentage of crystallized sugar is produced under manual control using instruments that arguably do not provide actionable information, and apparently

Our comprehensive offer for the sugar industry Siemens

(PDF) State-based approach of sugar boiling process

Vaccum Pan| Continuous Vacuum Pan Rapid Boiling Pan

A career in the sugar industry is for you! (The sugar industry directly employs about 17,000 people within the growing, harvesting, milling and transport sectors …

Full text of “CANE SUGAR INDUSTRY” Internet Archive

OUTLOOK FOR EMERGING TECHNOLOGIES IN SUGAR PROCESSING

Comments are closed.